Manufacturing method for multi-color quartz stone board

A technology for manufacturing devices and double-color plates, which is applied in the field of plate production equipment, can solve the problems of reducing the production efficiency of quartz stone double-color plates, manual handling, time-consuming and labor-intensive problems, and achieve the effects of shortening the production cycle, ensuring quality, and reducing the probability of errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

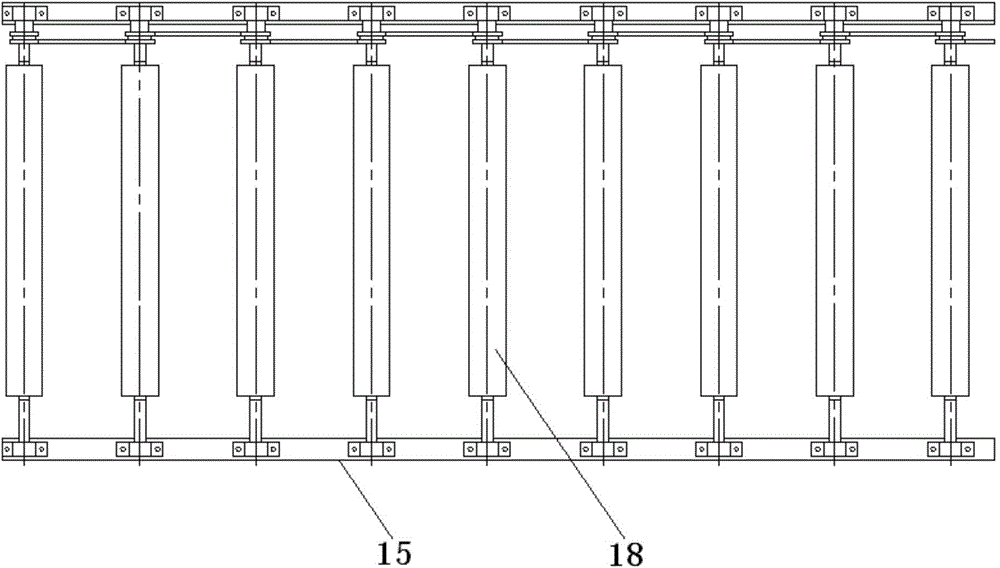

[0017] Quartz stone compound color plate manufacturing device provided by the invention, its structure is as figure 1 and figure 2 As shown, it includes a frame 2, a transmission device installed on the frame 2, a batching hopper 4 placed on the transmission device, and more than two horizontally distributed mixers 1 installed on the frame, and the transmission device and the batching hopper are located at Below the mixer, the conveying equipment includes a feed conveyor belt 3 and a discharge conveyor belt 12, the feed conveyor belt is located below the discharge port of the mixer, the discharge conveyor belt is parallel to the feed conveyor belt, and is positioned on the same plane as the feed conveyor belt, and the feed conveyor belt is placed on the same plane as the feed conveyor belt. Both the conveyor belt and the discharge conveyor belt are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com