A kind of thick seamless velvet pantyhose for abdominal tightening and hip raising and manufacturing method thereof

A manufacturing method and technology of pantyhose, applied in the direction of pantyhose, socks, textiles and papermaking, etc., can solve problems such as seam breaks, uncoordinated wearing, stuffy heat, etc., and meet the requirements of simple production process, generous aesthetics, The effect of heat preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to describe the present invention in more detail, reference is made below to the accompanying drawings.

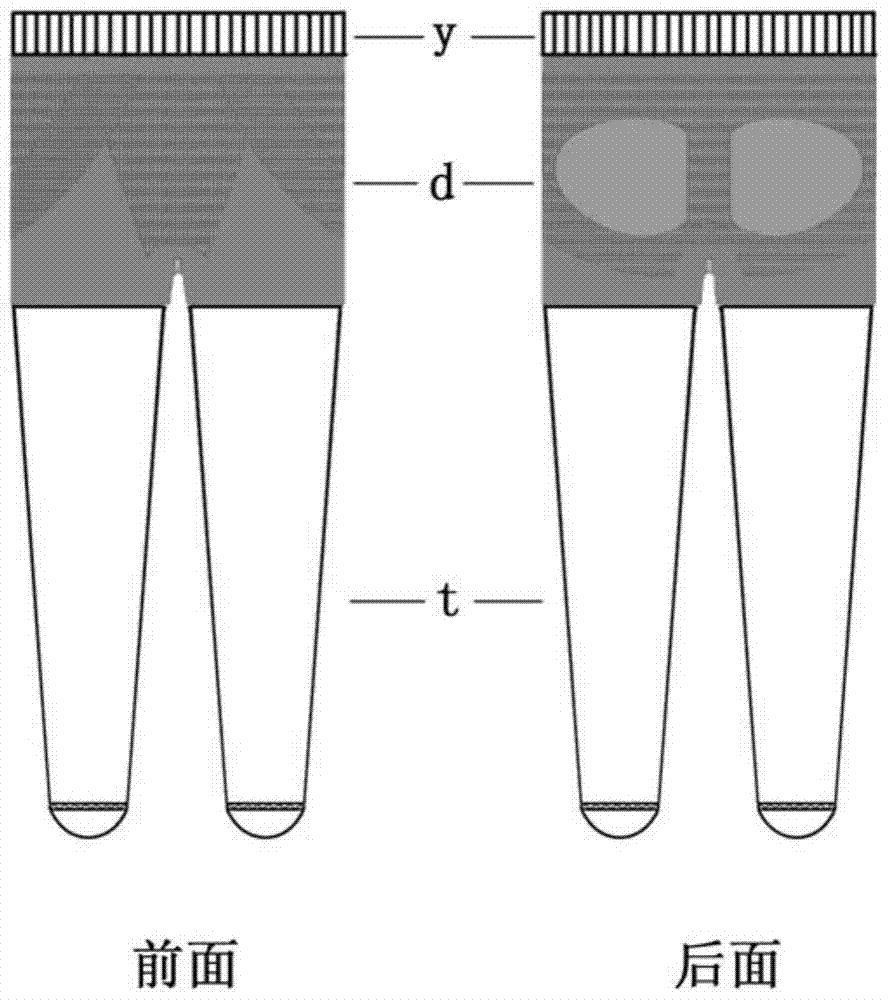

[0037] Such as figure 1 As shown, the thick seamless velvet pantyhose of the present invention is composed of a waist y, a crotch d, and a trouser leg t.

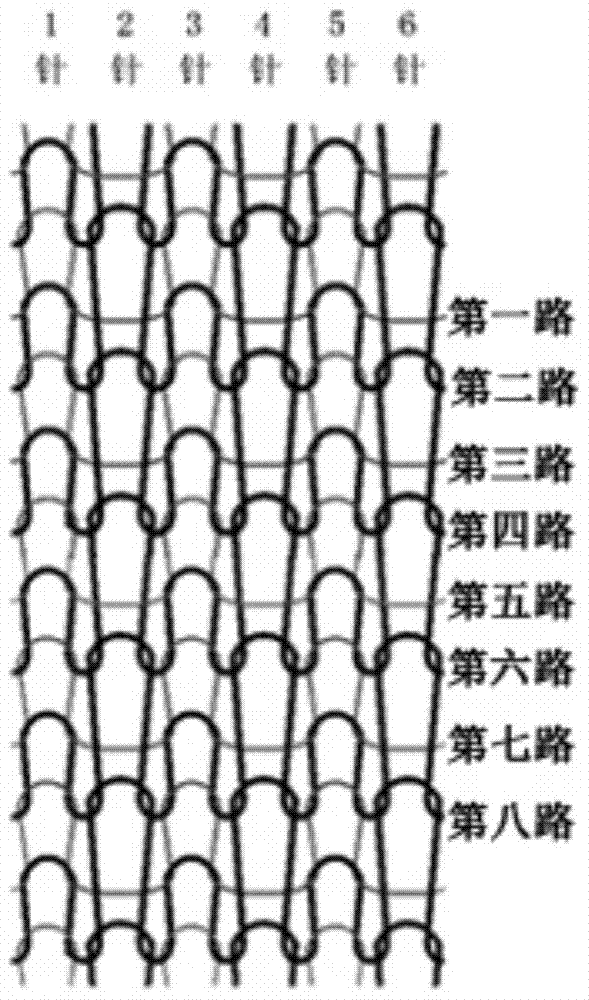

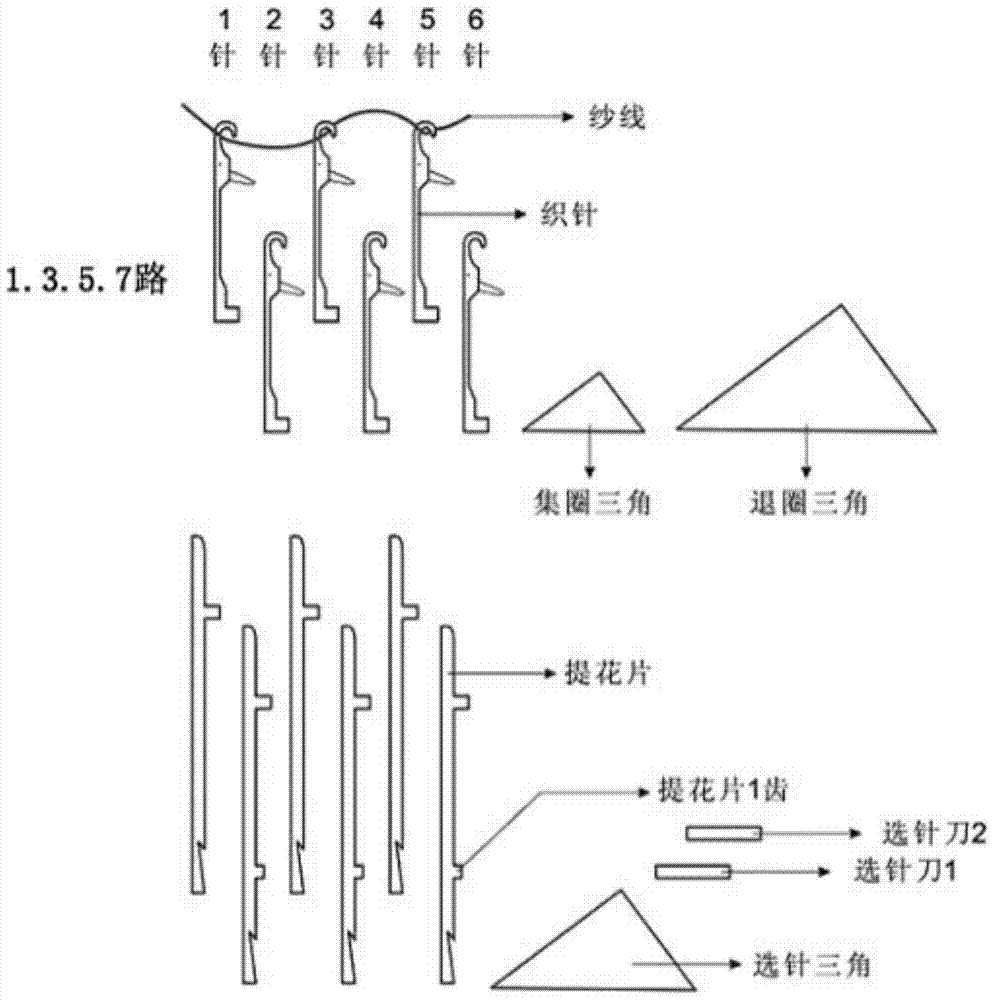

[0038] The trouser waist y is woven with an eight-way feeder underwear machine, and the double-layer tie is woven with 1*1 fake rib weave. Such as Picture 1-1 The schematic diagram of the 1*1 false rib weave shown, the 1st, 3rd, 5th, 7th way 1, 3, 5... odd-numbered needles form a loop, 2, 4, 6... even-numbered needles do not form a loop to form a floating line; the second , 4, 6, and 8 stitches are all looped; then repeat this knitting. To achieve such an organization, such as Figure 1-2 As shown, remove 1 tooth of 1, 3, 5... odd-numbered jacquard pieces, leave 1 tooth of 2, 4, 6... Needle knife 2 quits working. On the one hand, because 2, 4, 6... even-numbered jacquard pieces have 1 tooth, so wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com