New motor housing structure based on detachable support base

A technology for motor shells and support seats, which is applied in the direction of casings/covers/supports, electrical components, electromechanical devices, etc., which can solve the problem of insufficient length of the working part of the connecting bolts, reduce the service life of the support seat, and affect the normal operation of the motor And other problems, to achieve the effect of preventing thread damage, convenient production, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

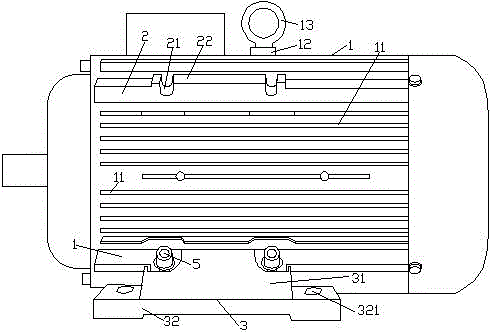

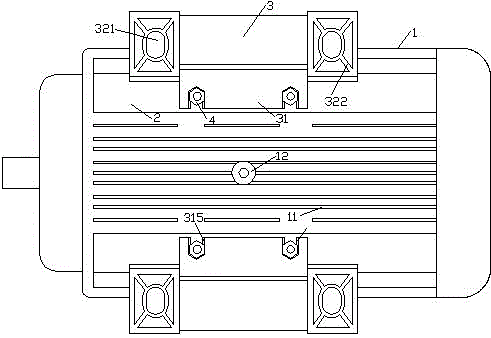

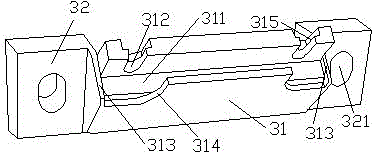

[0018] refer to Figure 1 to Figure 5

[0019] A new type of motor housing structure based on a detachable support seat, including a cylindrical motor housing 1, at least a pair of connecting ribs 2 are arranged at intervals along the outer circumference of the motor housing, so as to install the motor according to the Choose which two adjacent connecting ribs to use. The connecting ribs are arranged at intervals along the length direction with U-shaped notches 21 for passing bolts. The use of such U-shaped notches is also convenient for installation and disassembly, and avoids the need for hole positioning during installation. A detachable support seat 3 for connecting with the frame is provided on the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com