A Milling Stability Prediction Method Based on Legendre Polynomials

A stability prediction, polynomial technology, used in prediction, instrumentation, manufacturing computing systems, etc., can solve the problem that the accuracy of the calculation method has not been improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

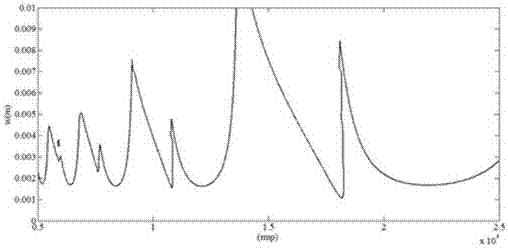

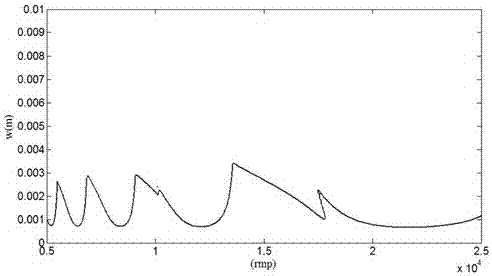

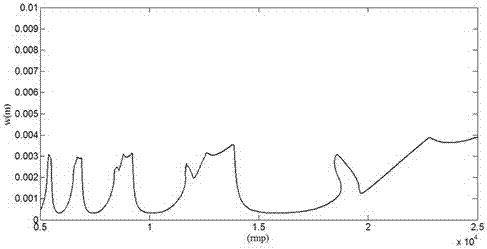

Image

Examples

Embodiment Construction

[0127] The present invention comprises the following steps:

[0128] ① Establish the dynamic equation of the milling cutter in the single-degree-of-freedom milling process:

[0129]

[0130] in, is a constant coefficient matrix, is the coefficient matrix that changes with the time period, x(t) represents the state response of the tool at time t, ω n Indicates the natural frequency of the tool tip point, ζ indicates the relative damping, m t Indicates the modal quality, w indicates the axial cutting depth, and τ indicates the time lag;

[0131] h(t) represents the instantaneous chip thickness, and its expression is:

[0132]

[0133] In formula (2), N represents the number of teeth of the milling cutter, K t and K n are the cutting force coefficients in the tangential and normal directions, respectively, φ j (t) is the angular displacement of the jth tooth, the expression is φ j (t)=(2πΩ / 60)t+(j-1).2π / N, window function g(φ j (t)) is defined as:

[0134]

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com