Control system for flexible tools for assembly of wing foreparts

A technology of flexible tooling and control systems, applied in the direction of digital control, electrical program control, etc., can solve the problem that rigid tooling cannot meet the requirements of various wing flaps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

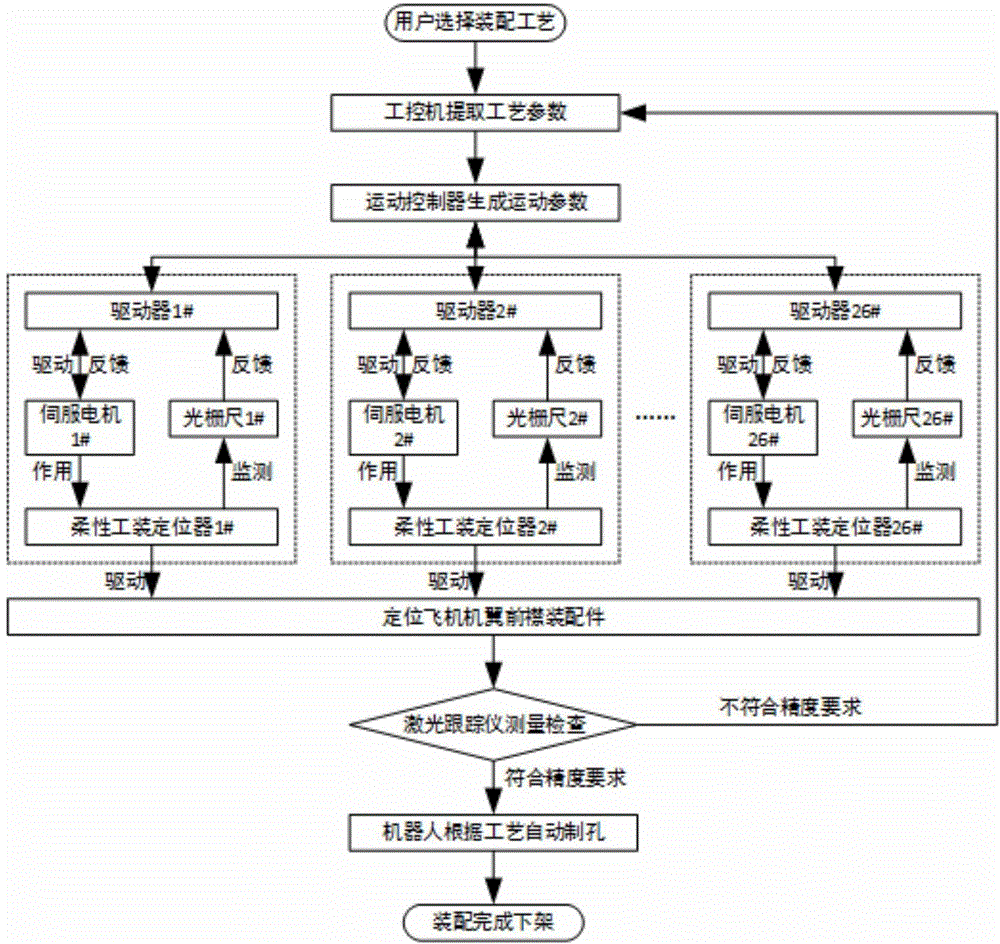

[0018] This embodiment is a flexible tooling control system for assembling the front flap of the wing. The single-axis servo motor on the SERCOS-III bus node is controlled by the motion controller to realize the motion control of the entire set of flexible tooling for the front flap of the wing, and to digitize the front flap of the wing. assembly.

[0019] see figure 1 , figure 2 , The control structure of the flexible assembly unit of the leading edge flap adopts the multi-level distributed control method introduced by the field bus.

[0020] The industrial computer 1 communicates control commands and status information with the motion controller 2 , the laser tracker controller 6 and the robot controller 7 through the TCP / IP network.

[0021] The industrial computer 1 communicates with the TCP / IP network communication module 3 in the motion controller 2 through the TCP / IP network. The driver 10 of the motion unit 8 sends motion control commands, and simultaneously colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com