Helium circulating system

A circulatory system, helium technology, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of helium waste, inability to recycle, and lack of systems and devices that can guarantee the purity of helium.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

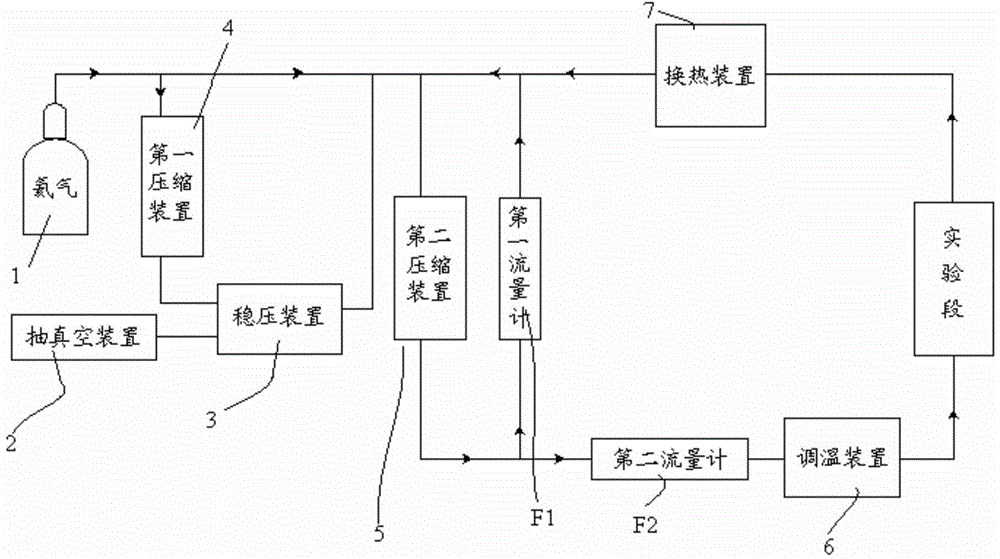

[0023] Such as figure 1 , figure 2 As shown, a helium circulation system provided by the present invention includes a helium cylinder 1, a heat exchange device 7, a vacuum device 2, a voltage stabilizing device 3, a first compression device 4, a second compression device 5, and a temperature adjustment device 6. Experiment section 8.

[0024] The helium cylinder 1 is connected to the stop valve V11, and then connected to the pressure indicator P11 and the stop valve V12 in turn. The stop valve V12 is connected to the pressure indicator P11 and the temperature indicator T11 in turn, and then connected to the input end of the second compression device 5. The device 5 includes a compressor 51, the input end of the compressor 51 is connected with a pressure indicator P51 and a temperature indicator T51, and the output end of the compressor 51 is sequentially connected with a regulating valve V51, a first flow meter F1, and an exhaust valve V53, and then connected to To the inpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com