Two-way bearing heavy load guide rail pair

A guide rail pair, guide rail technology, applied in the direction of bearings, shafts and bearings, linear motion bearings, etc., can solve the problems of limited application scope, increased size, and reduced stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

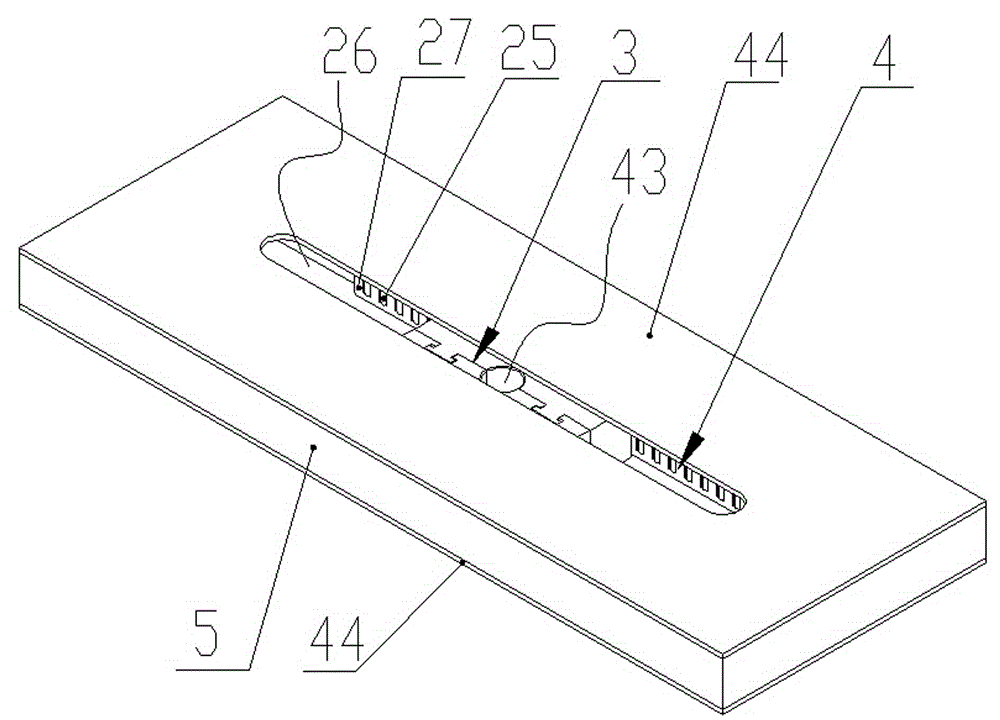

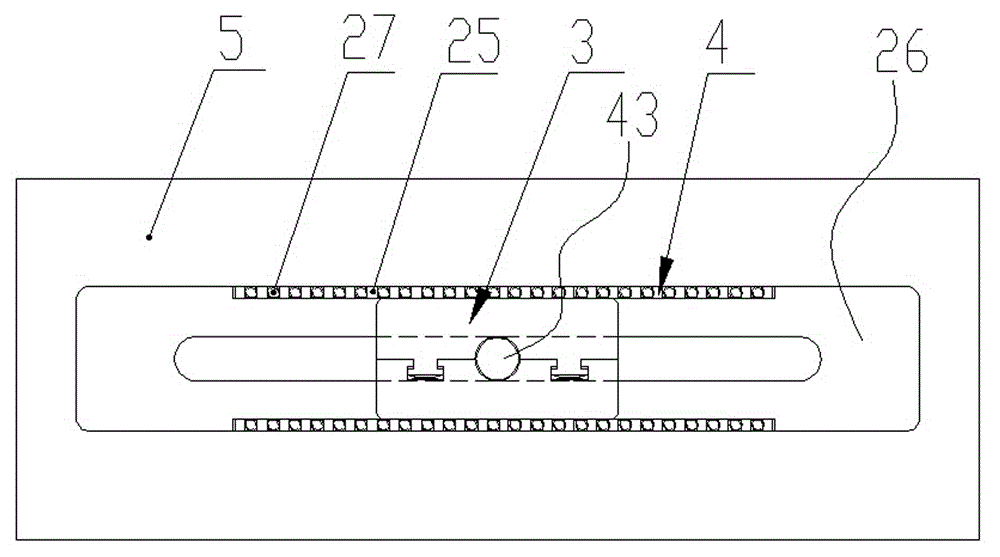

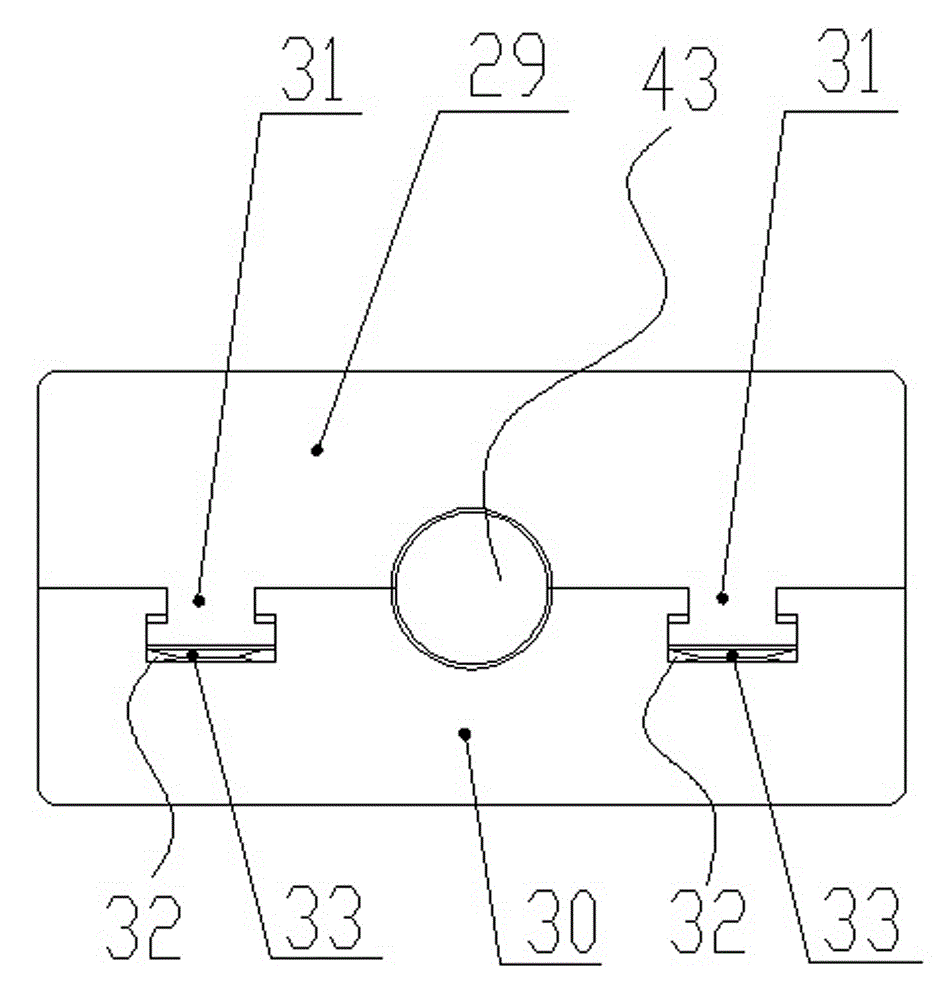

[0017] Combine below Figure 1 to Figure 4 The structure and working process of the present invention are further described.

[0018] A two-way force-bearing heavy-duty guide rail pair, which includes a guide rail frame body 5 provided with a guide rail groove 26, and a self-tensioning slider 3 matched with it is provided inside the rail groove 26, and the self-tensioning slider A roller row 4 is arranged between both sides of the block 3 and the inner wall of the guide rail groove 26, and the roller row 4 is composed of a roller row 27 and a roller cage 25, and the roller cage 27 is provided with a Roller rows 25 are matched with roller positioning holes arranged in a grid structure (not marked in the drawings), each roller of the roller row 25 is arranged in the roller positioning holes, and the rollers Both sides of the roller in the column positioning hole are rollingly connected with the self-tensioning slider 3 and the inner wall of the guide rail groove 26; the self-te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com