A pile hole construction method for underground engineering

A construction method and underground engineering technology, which is applied to earth drilling, mining equipment, tunnels, etc., can solve the problems of violating the scientific development concept, poor adaptability, unreasonableness, etc., and achieve clear structural force path, fast construction, and high quality reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

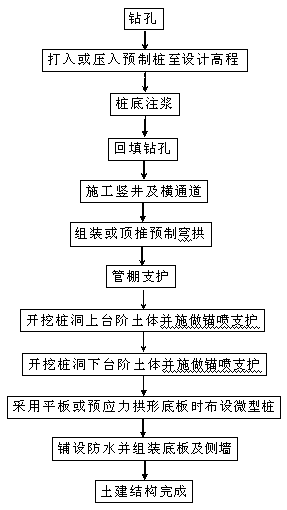

[0054] combine Figure 2 to Figure 10 , the construction steps are introduced as follows:

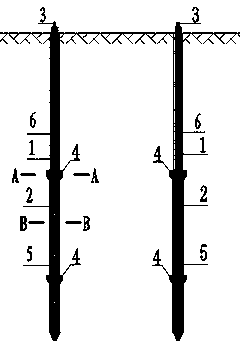

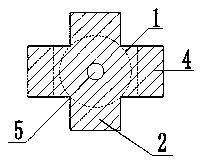

[0055] Step 1: Drill holes on the road surface, mechanically drive or press prefabricated piles to the design elevation, to ensure the compaction effect of the piles, reserve a long hole in the middle of the prefabricated piles, the hole diameter is 10cm, and place positioning rods with grouting function, prefabricated During the process of driving or pressing the pile, the positioning rod controls the accuracy of the pile. See the cross-sectional schematic diagram and corresponding section Figure 2-Figure 4 As shown; the prefabricated piles are provided with two-way corbels at the level of the arch and the floor;

[0056] Step 2: Carry out grouting at the bottom of the pile, fill the borehole with plain concrete, and repair the road surface. See the cross-sectional schematic diagram Figure 5 shown;

[0057] Step 3: Construct the shaft on the side of the road, construct the cross p...

Embodiment 2

[0064] Among them, the excavation height of the soil body of the upper step is 2m, and the prefabricated dome is pushed up, and the other schemes are the same as in Embodiment 1.

Embodiment 3

[0066] Among them, the diameter of the anchor rod and the micro-pile is 15cm, and the angle between the anchor rod and the horizontal line is 5 degrees and it is obliquely downward. The cross-sectional schematic diagram is shown in Figure 8 Shown; Other schemes are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com