A quantitative evaluation device and method for engineering simulation and quantitative evaluation of cementing prefluid flushing efficiency

A technology for cementing pre-fluid and simulation and quantification, which is applied in the field of petroleum drilling engineering, can solve the problem that the optimal amount of pre-fluid, flushing time, and displacement construction parameters cannot provide scientific guidance and cannot truly simulate the existence of filter cake in the well. It can reduce the experimental workload, visualize the process, and optimize the flushing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

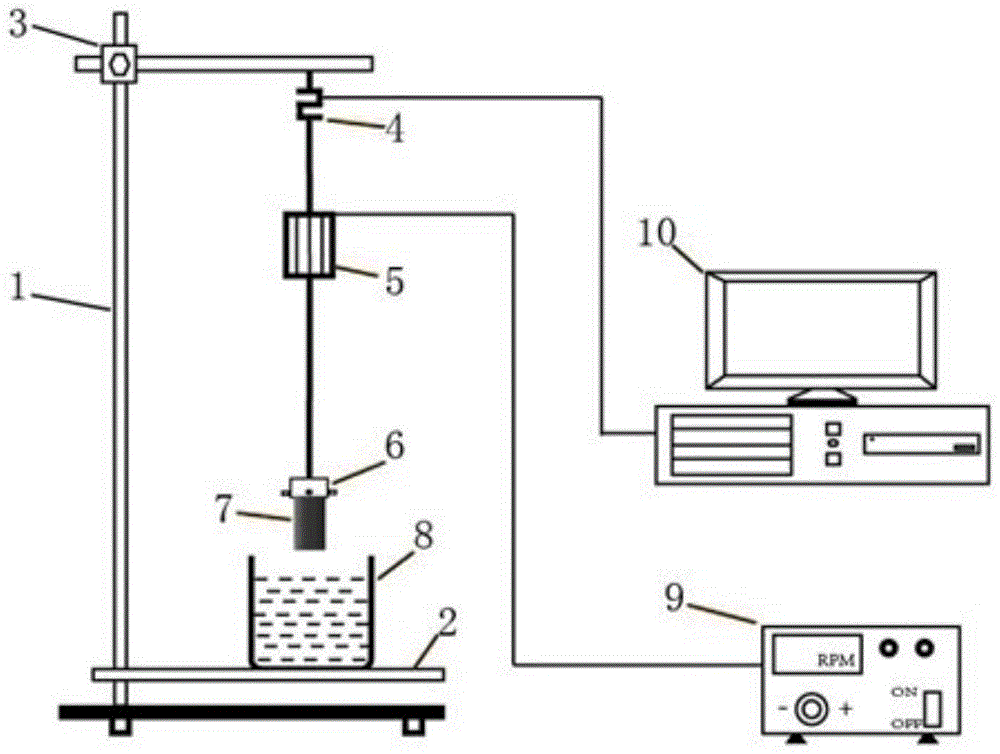

Method used

Image

Examples

Embodiment 1

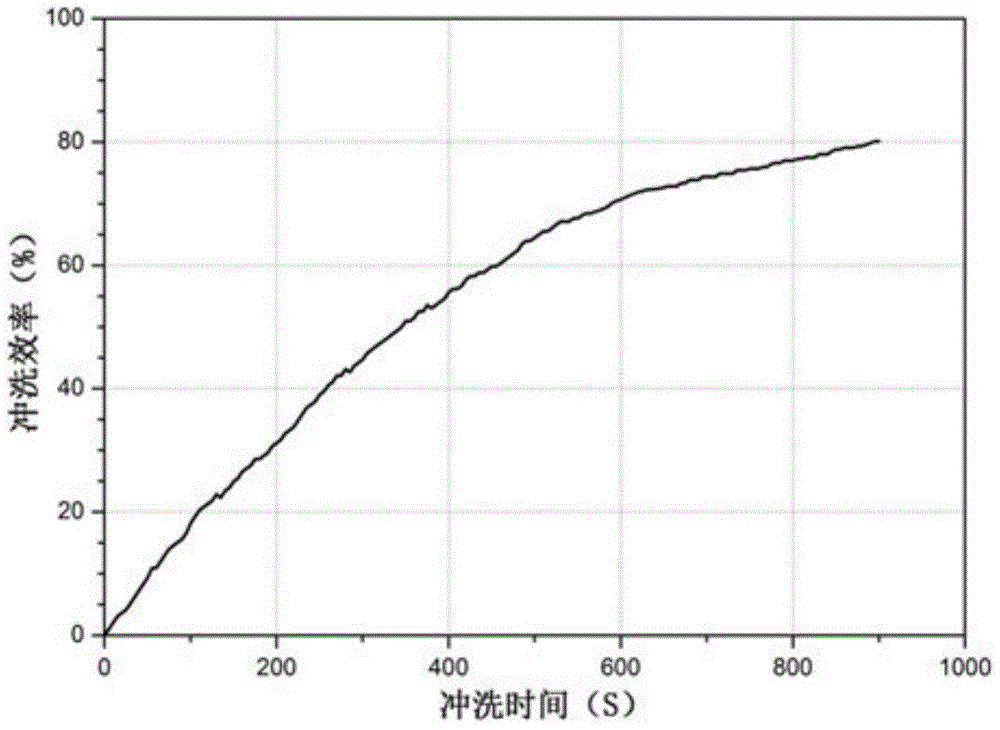

[0044] Example 1 Drilling Fluid Flushing Efficiency Test Experiment

[0045] In a well in western Sichuan, a 139.70mm casing was run in a 215.90mm diameter hole, and the drilling fluid system was used with a density of 1.52g / cm 3 The sulfonated drilling fluid system is designed to replace the drilling fluid with pad fluid A at an annular return velocity of 0.8m / S, and the design flushing time is 15min. The evaluation device and method of the present invention are used to evaluate the flushing efficiency of prefluid A under the operating parameter conditions.

[0046] In the first step, the mass of the artificial rock core is weighed to be 112.36g. The second step is to put the artificial rock core in the high temperature and high pressure water loss instrument, pour in the drilling fluid on site and cover the core, use a nitrogen bottle to inject a pressure of 3.5MPa into the high temperature and high pressure water loss instrument, and release the pressure after 20 minutes t...

Embodiment 2

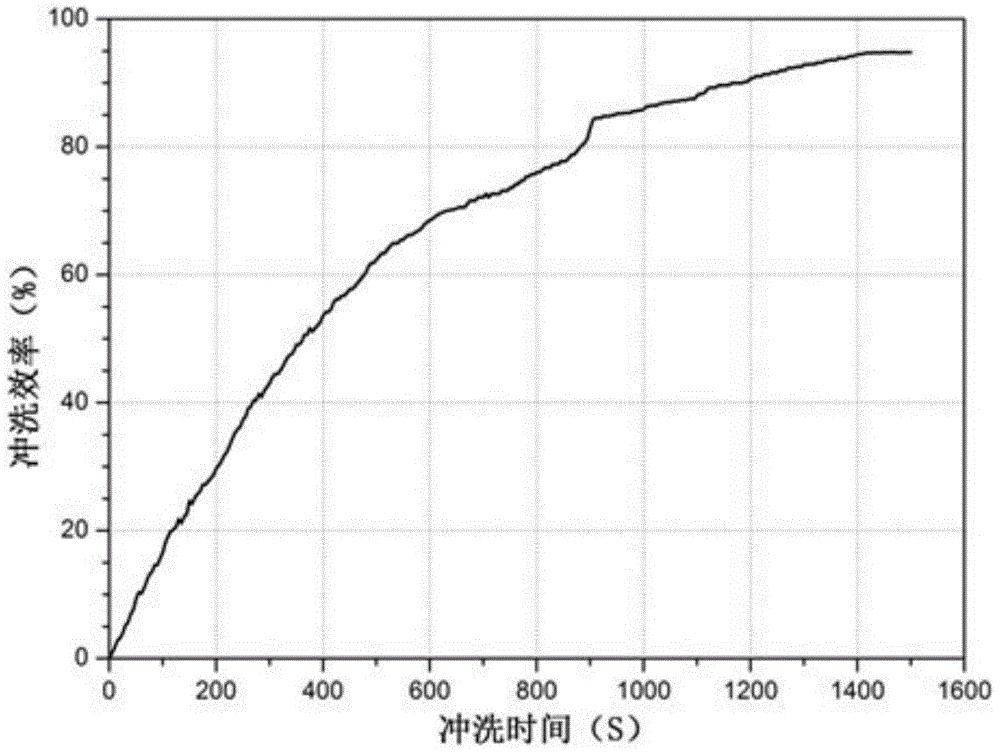

[0047] The optimization of embodiment 2 preflush flushing time

[0048] The steps are the same as in Example 1, other conditions remain unchanged, only the flushing time of the pre-fluid A is extended, and the variation of the flushing efficiency with the flushing time is investigated, the test results are as follows image 3 shown. From image 3 It can be seen that the flushing efficiency is 82.95% when the flushing time reaches 15 minutes, and the result is consistent with the result of Example 1. It also shows that the flushing efficiency under different flushing time conditions can be evaluated by extending the flushing time by using the device of the present invention, and a large number of Save experimental workload. When the flushing time reaches more than 23 minutes, the flushing efficiency remains at about 94% and does not change, indicating that under the condition of 0.8m / s annular velocity, the preflush flushing time must be designed at least 23 minutes to obtain...

Embodiment 3

[0049] The optimization of embodiment 3 prefluid return velocity

[0050] On the basis of Example 1, other conditions remain unchanged, except that the annulus return velocity of the prefluid A is increased to 1.0m / s, and the corresponding core rotation speed is increased to 478r / min, and the flushing efficiency after flushing for 15 minutes is investigated, and the following is obtained The final flushing efficiency is 90.48%, the test results are as follows Figure 4 shown. From Figure 4 It can be seen from the figure that when the return speed is increased, the flushing efficiency increases rapidly in the early stage, and gradually tends to be stable in the later stage, indicating that properly increasing the return speed can improve the flushing efficiency when the amount of prefluid is insufficient or the sealing section is long.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com