Cable climbing robot

A crawling robot and cable technology, applied in the field of robotics, can solve problems such as the inability to change the gripping force of the robot on the cable, the inability to control the recovery of the robot, and the inability to use the cable, etc., to achieve good passability, large clamping force, and strong obstacle-crossing ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

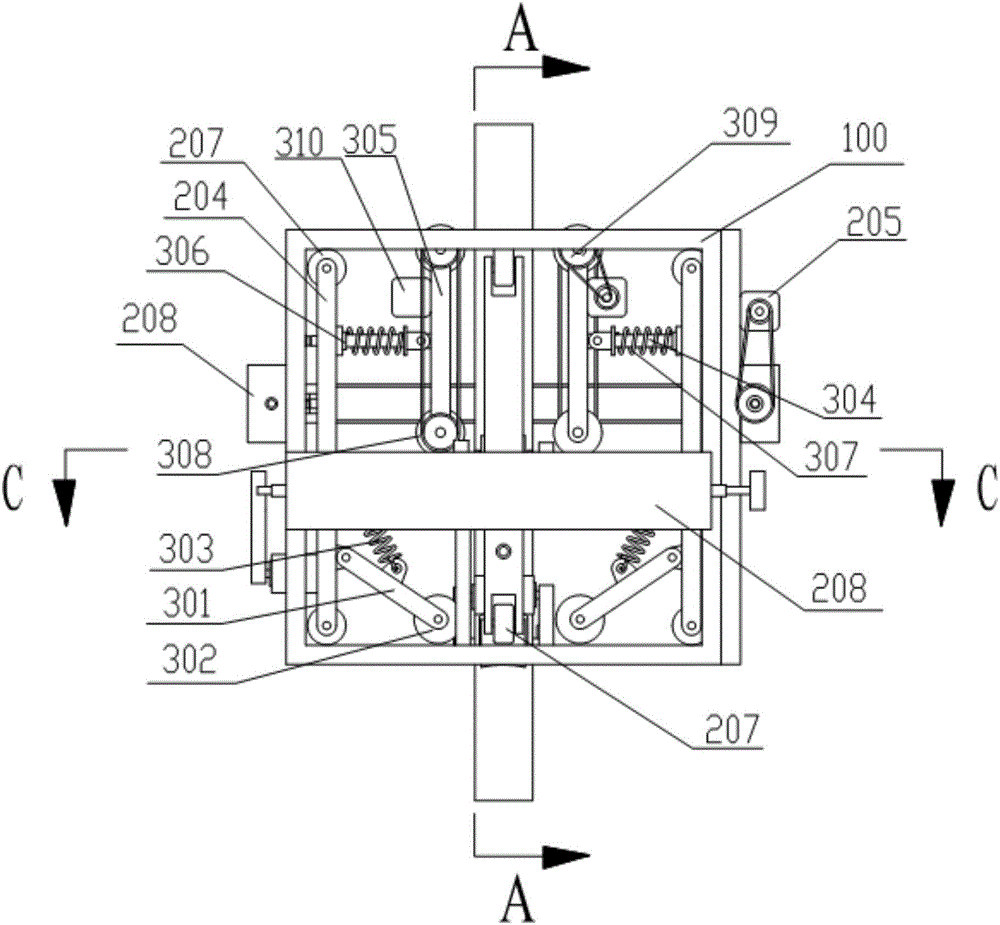

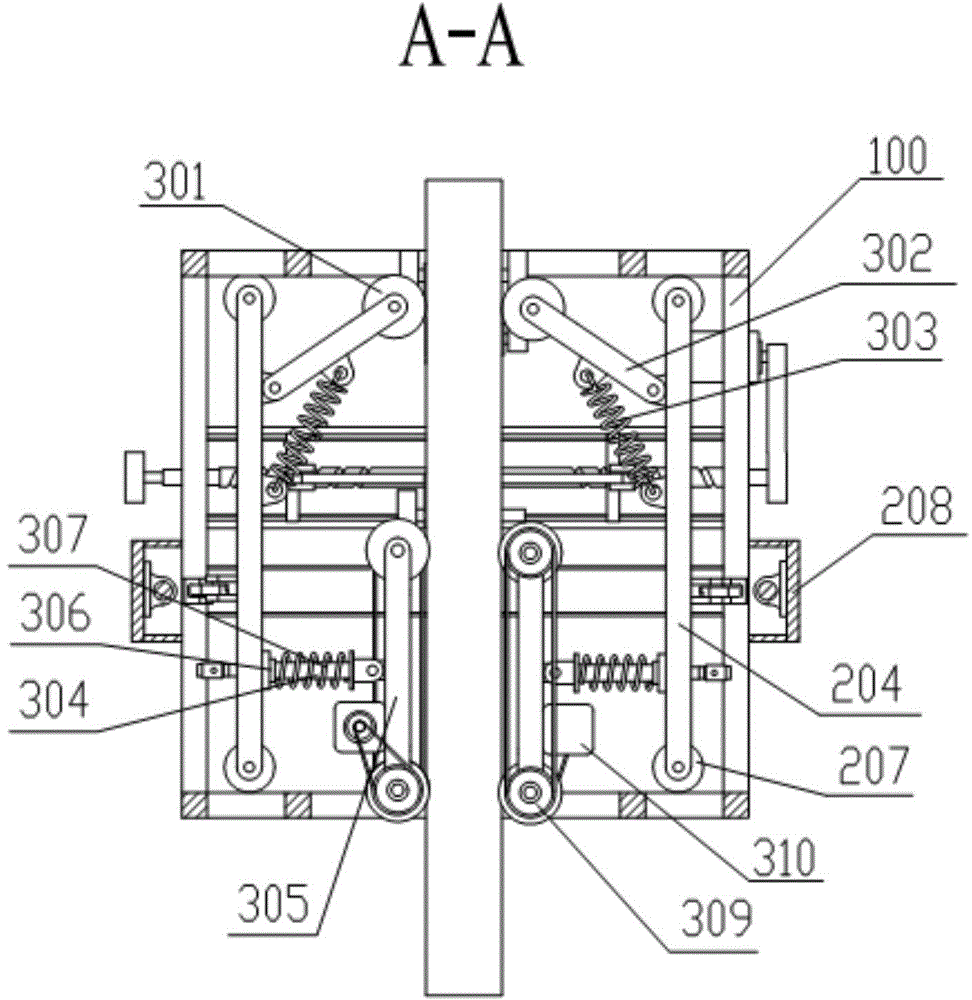

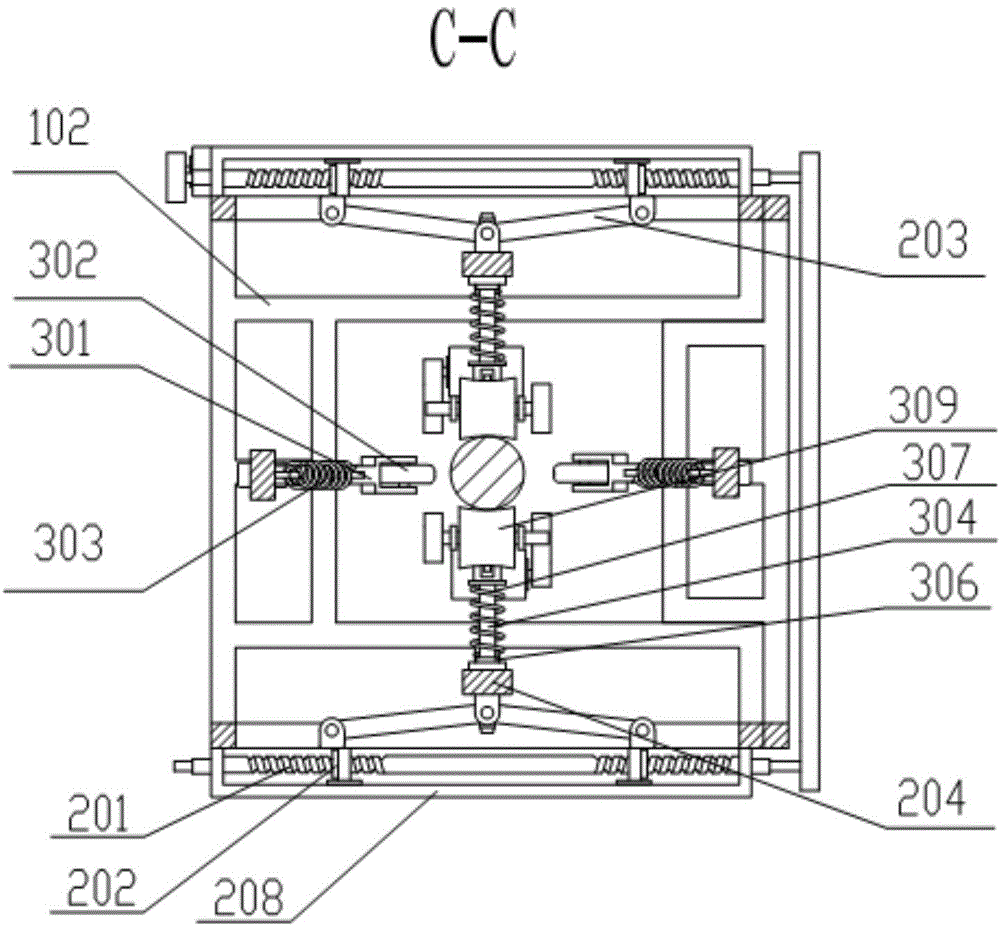

[0036] Figure 1-5 As shown, a specific embodiment of the present invention is: a cable crawling robot, including an outer frame 100, a clamping mechanism and a crawling mechanism on the outer frame 100, and its structural characteristics are:

[0037] The outer frame 100 is a cube frame; each side of the upper surface and the lower surface of the outer frame 100 is connected with the inner side frame 102 through the radial frame 101, and each side of the outer frame 100 has a clamping mechanism and crawling mechanism;

[0038] The specific composition of each clamping mechanism is: between the vertical rods on the side of the outer frame 100, the ball screw 201 with opposite rotation on both sides is connected by bearings, and the screw nuts 202 on both sides of the ball screw 201 are hinged with connecting rods 203 , the other ends of the two connecting rods 203 are jointly hinged on the hinge shaft at the back of the vertical clamping support plate 204, and the ball screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com