Light-weight and convenient type steel rail corrugation grinding machine

A portable, grinding mechanism technology, used in tracks, track laying, track maintenance, etc., can solve the problems of low grinding precision and efficiency, and achieve the effects of high grinding precision, cost reduction and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

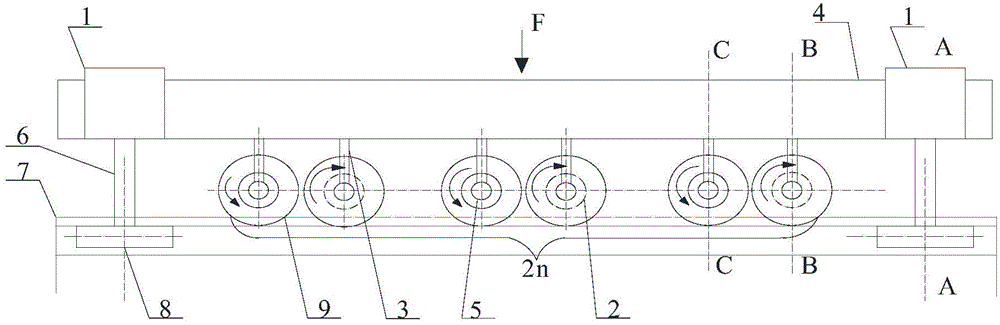

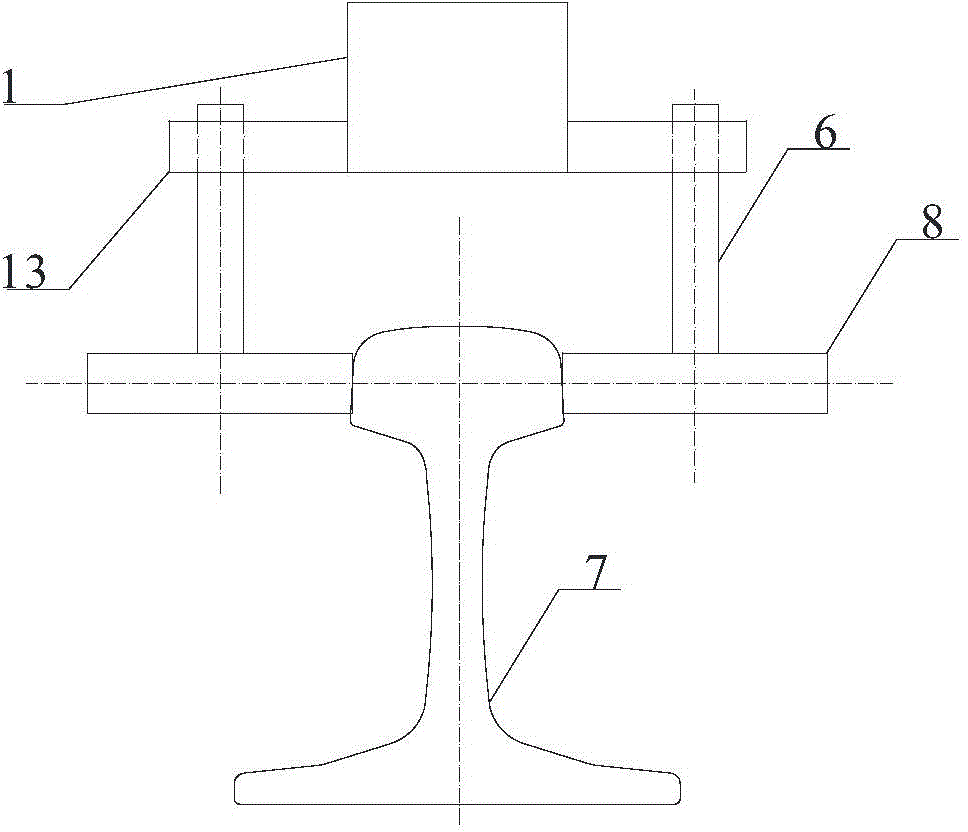

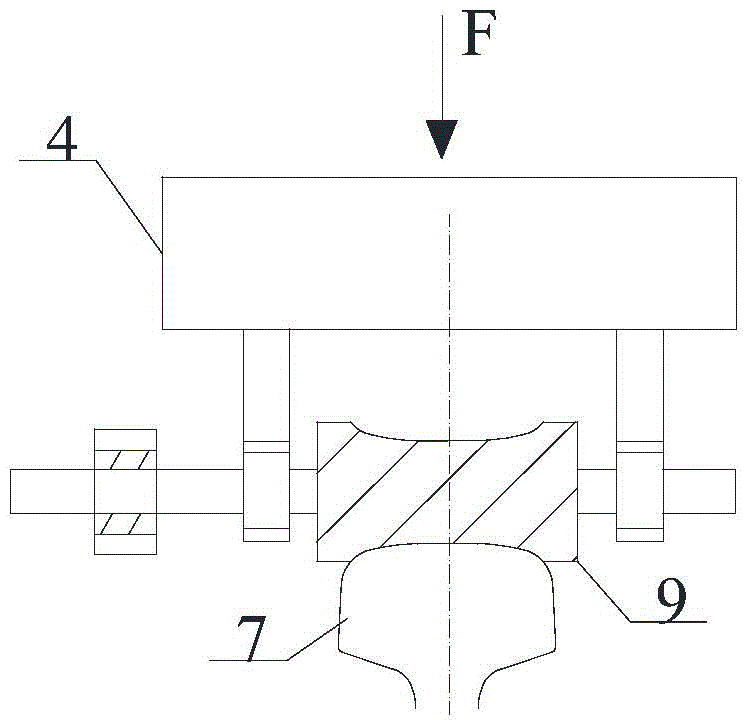

[0037] Such as figure 1 and Figure 6 As shown, the present embodiment provides a portable rail corrugation grinding machine for corrugating and grinding the rail 7, including a support beam 14, one end of the support beam 14 is provided with a support device, and the other end is provided with a grinding device. It includes a grinding mechanism frame 4, a clamping guide assembly for clamping and guiding the rail and a grinding assembly for moving relative to the rail and grinding the rail. There are two clamping guide assemblies, which are respectively located on the grinding mechanism frame 4. At the end, there are multiple grinding components connected to the bottom of the grinding machine frame 4, and sequentially arranged between two clamping guide components. The support beam 14 is vertically arranged with the grinding machine frame 4 .

[0038] The grinding mechanism frame 4 is kept parallel with the standard rail surface, and all devices of the whole grinding machine...

Embodiment 2

[0046] Such as Figure 4 and Figure 5 As shown, in the present embodiment, the transmission wheel 2 of the adjacent grinding assembly is located on the same side of the transmission wheel shaft 5, and the grinding wheel support 3 is fixedly connected to the grinding mechanism frame 4, between the transmission wheel shaft 5 and the bearing 10, between the transmission wheel shaft 5 and the Transmission wheel 2 is all provided with a guide mechanism for guiding the lateral movement of grinding wheel 9, so that the grinding wheel grinding head in the middle has transverse momentum, which is suitable for grinding of a single rail wave-type wear in a curved section with small radius. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com