A kind of large single crystal graphene and preparation method thereof

A single crystal graphene, polymethyl methacrylate technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the adverse effects of electrical properties, the small size of the single crystal domain area, the oxidation group Doping and other problems, to achieve the effect of simple and effective preparation method, reduced nucleation density, and high quality of single crystal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

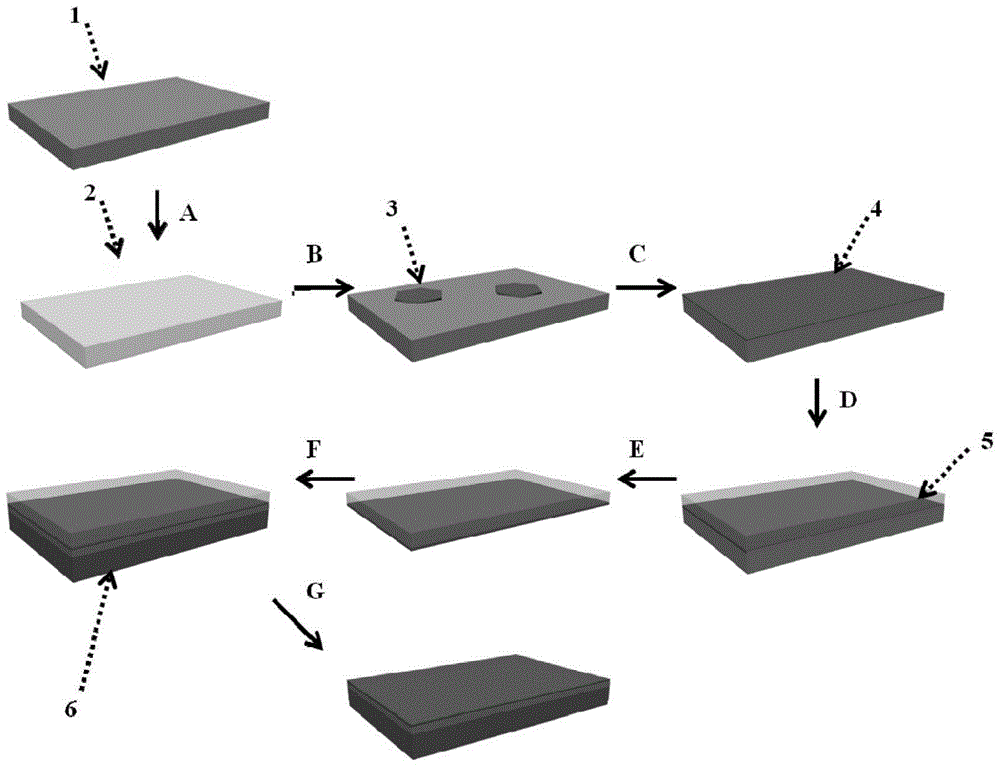

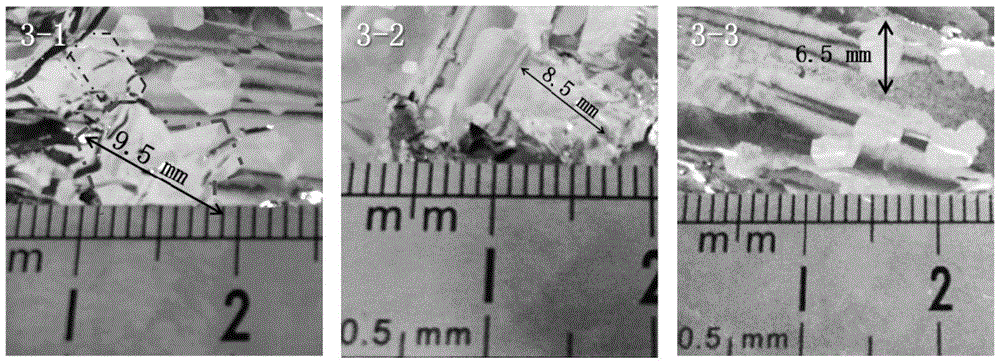

[0050] Embodiment 1, prepare large single crystal graphene

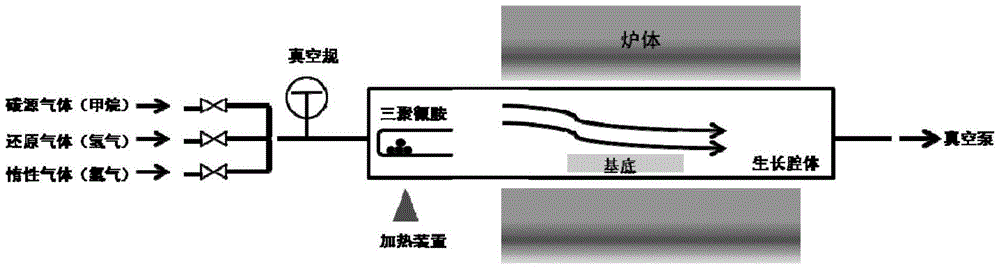

[0051] (1) Use dilute hydrochloric acid with a mass fraction of 5% and deionized water to clean the copper foil (produced by Alfa Aesar, with a purity of 99.8%, and a thickness of 25 μm) in sequence, place the copper foil in a casing with a magnetic control device, and then Put the casing in a tube furnace, under a hydrogen atmosphere with a flow rate of 100 sccm, and a system pressure of 100 Pa, raise the temperature of the furnace body to 1020°C and keep it for 30 minutes;

[0052] (2) Keep the temperature of the furnace body at 1020°C, turn off the hydrogen flow, and feed in the argon gas with a flow rate of 100 sccm. At the same time, heat 2 g of melamine solids (Bailingwei Company, purity 99.8%) in the heating belt, and set the temperature of the heating belt at 120° C. , the system pressure is 100Pa, the treatment time is 10min, and the treatment of the copper foil surface is completed;

[0053] (3) Keep the t...

Embodiment 2

[0060] Embodiment 2, prepare large single crystal graphene

[0061] (1) Using phosphoric acid and ethylene glycol solution with a mass ratio of 3:1 as the electrolyte, copper foil (produced by Alfa Aesar, with a purity of 99.8%, and a thickness of 25 μm) was connected to the positive electrode, and polished at a DC current of 0.5 A for 30 min. Put the copper foil in a sleeve with a magnetic control device, then place the sleeve in a tube furnace, raise the temperature of the furnace body to 1020°C under a hydrogen atmosphere with a flow rate of 300 sccm, and keep the system pressure at 300 Pa. 50min;

[0062] (2) Keep the temperature of the furnace body at 1020°C, turn off the hydrogen flow, and feed in the argon gas with a flow rate of 500 sccm. At the same time, heat 2 g of melamine solids (Bailingwei Company, purity 99.8%) in the heating belt, and set the temperature of the heating belt at 120° C. , the system pressure is 500Pa, the treatment time is 10min, and the treatme...

Embodiment 3

[0069] Embodiment 3, prepare large single crystal graphene

[0070] (1) Using phosphoric acid and ethylene glycol solution with a mass ratio of 3:1 as the electrolyte, copper foil (produced by Alfa Aesar, with a purity of 99.8%, and a thickness of 25 μm) was connected to the positive electrode, and polished at a DC current of 0.5 A for 30 min. Put the copper foil in a sleeve with a magnetic control device, then place the sleeve in a tube furnace, and raise the temperature of the furnace body to 1020°C under a hydrogen atmosphere with a flow rate of 100 sccm, and keep the system pressure at 100 Pa. 30min;

[0071] (2) Keep the temperature of the furnace body at 1020°C, turn off the hydrogen flow, and feed in the argon gas with a flow rate of 500 sccm. At the same time, heat 2 g of melamine solids (Bailingwei Company, purity 99.8%) in the heating belt, and set the temperature of the heating belt at 120° C. , the system pressure is 500Pa, the treatment time is 10min, and the tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com