A method for improving the enzymatic hydrolysis efficiency of raw starch

A technology of enzymatic hydrolysis efficiency and raw starch, which is applied in the field of starch sugar production, can solve the problems of reduced starch enzymatic hydrolysis efficiency, low enzymatic hydrolysis efficiency, unfavorable starch sugar production cost, etc., to overcome energy consumption, improve enzymatic hydrolysis efficiency, reduce The effect of evaporation energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The assay method of embodiment 1 raw amylase enzymatic activity

[0021] Use 1% soluble starch solution as the substrate (pH 4.0), add 0.5mL enzyme solution to 20mL substrate, react at 40°C for 10min, immediately add 0.5mL 0.1mol / L NaOH solution to terminate the reaction, after the reaction, the reaction solution Centrifuge at 8000r / min for 5min, and measure the glucose content in the supernatant by the dinitrosalicylic acid (DNS) method; use the inactivated enzyme solution as a control. Definition of amylase enzyme activity: In the above reaction system, the amount of glucose produced per minute is defined as one enzyme activity (U).

Embodiment 2

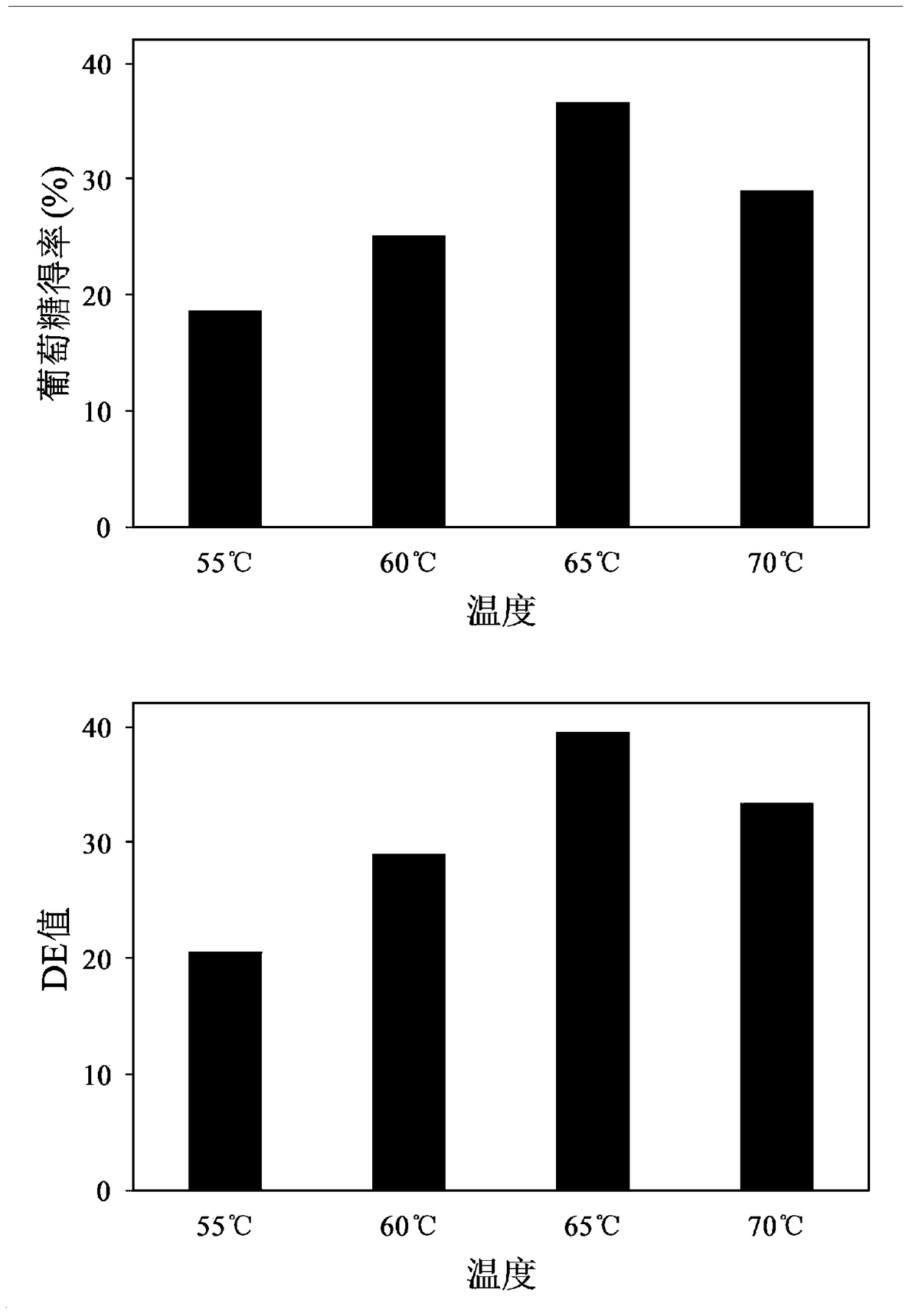

[0022] Example 2 The effect of temperature on the hydrolysis of 30% (w / w) starch milk by raw amylase.

[0023] Prepare 30% starch milk and add it to a four-neck flask, adjust the pH to 4.0 at 55-70°C, add raw amylase to react for 2 hours, and measure the glucose content and reducing sugar content. Such as figure 1 It was shown that when the temperature was controlled at 65°C, the enzymatic hydrolysis effect of raw amylase on 30% starch milk was the best.

Embodiment 3

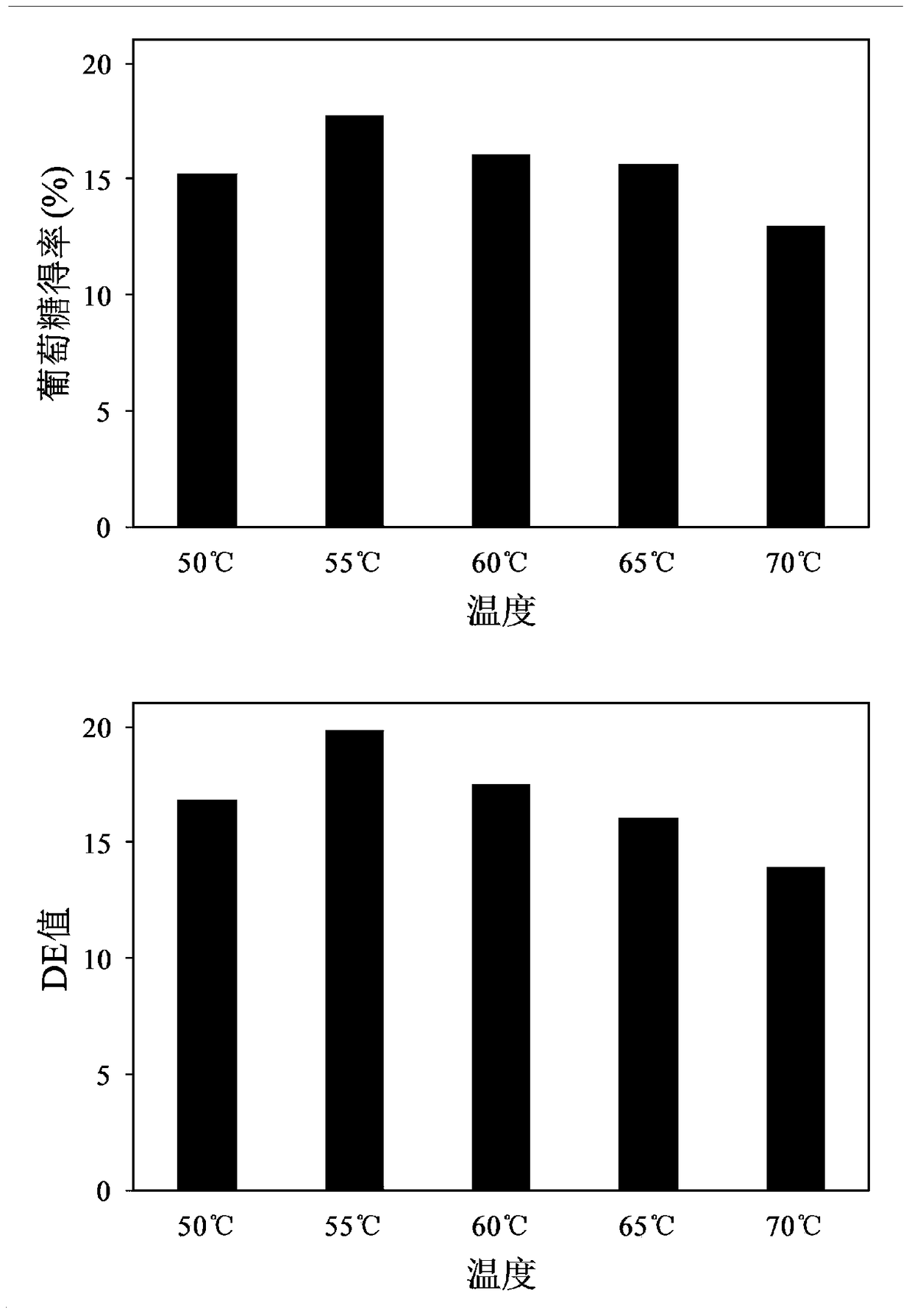

[0024] Example 3 Effect of temperature on enzymatic hydrolysis of 50% (w / w) starch milk by raw amylase.

[0025] Prepare 50% starch milk and add it to a four-neck flask, adjust the pH to 4.0 at 50-70°C, add raw amylase to react for 2 hours, and measure the glucose content and reducing sugar content. Such as figure 2 It was shown that when the temperature was controlled at 55°C, the enzymatic hydrolysis effect of raw amylase on 50% starch milk was the best.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com