Study of novel dimeric surfactant/polymer binary compound oil-displacing agent

A Gemini surface and active agent technology, which is applied in the field of binary compound oil displacement, can solve the problems of low oil recovery rate and unrecovered crude oil, and achieve enhanced oil recovery rate, high microcosmic oil displacement efficiency, and expanded spread volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Composition of binary compound oil displacement agent: A, sulfonate ester salt type gemini surfactant B, hydrophobically modified polyacrylamide

[0020] Using the Shengtuo sewage from Shengli Oilfield as the base fluid, the surfactant and polymer mother liquors with a mass fraction of 10% were prepared respectively, and stirred for later use.

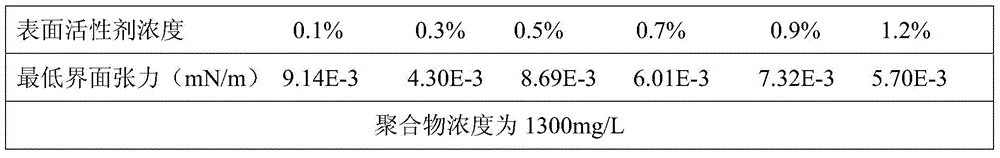

[0021] After diluting the above mother liquor with Shengtuo sewage by a certain number of times, mix the two according to a certain ratio. The polymer concentration in the mixed system is 1300mg / L, and the surfactant concentration is 0.1%, 0.3%, 0.5%, 0.7%, 0.9%. , 1.2%. Adjust the TEXAS-500 spinning drop interfacial tensiometer to 40°C, put the sample tube filled with the above solution into it, and after it stabilizes for half an hour, add about 1 microliter of crude oil from Shengli Oilfield with a micro-syringe, at a speed of 6000

[0022] At revolutions per minute, the lowest interfacial tension value that the measurement ...

Embodiment 2

[0025] Composition of binary compound oil displacement agent: A, carboxylate type gemini surfactant, B, hydrophobically modified polyacrylamide

[0026] Using the sewage from the Shengtuo area of Shengli Oilfield as the base fluid, the surfactant and polymer mother liquors with a mass fraction of 10% were prepared respectively, and stirred for later use.

[0027] After diluting the above mother liquor with sewage from the isolated island area to a certain number of times, mix the two according to a certain ratio. The polymer concentration in the mixed system is 1300mg / L, and the surfactant concentration is 0.1%, 0.5%, 0.7%, 0.9%. Adjust the TEXAS-500 spinning drop interfacial tensiometer to 60°C, put the sample tube filled with the above solution into it, and after it has stabilized for half an hour, add about 1 microliter of crude oil from Shengli Oilfield with a micro-syringe, at a speed of 6000 rpm , the lowest interfacial tension value achievable by the measurement syste...

Embodiment 3

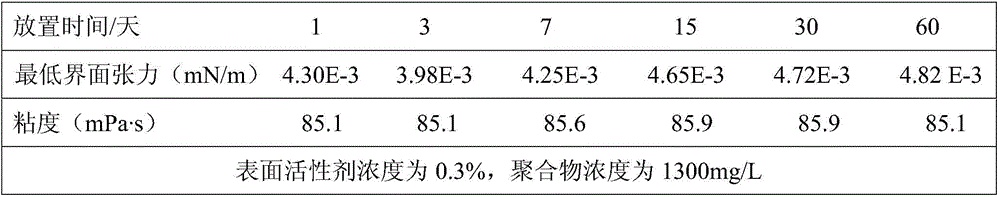

[0030] The binary compound system with specific concentration of polymer and surfactant solution concentration of 0.3% in Example 1 was placed in a thermostat at 60°C for 90 days, and the viscosity and minimum interfacial tension of the binary system were measured during this process value changes.

[0031] Depend on image 3 From the data, it can be seen that the interfacial tension and viscosity of the system will not change much during storage at a constant temperature of 90°C, indicating that the system has good stability under this compounding condition and is suitable for oilfield enhanced oil recovery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com