A continuous collection method and special device for single-walled carbon nanotube film

A technology of single-walled carbon nanotubes and special devices, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the uneven distribution of carbon nanotube films and the limitations of single-piece filter membrane collection methods Due to the types of substrates, pollutants and other issues, it can achieve good adaptability, easy disassembly and installation, and high quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

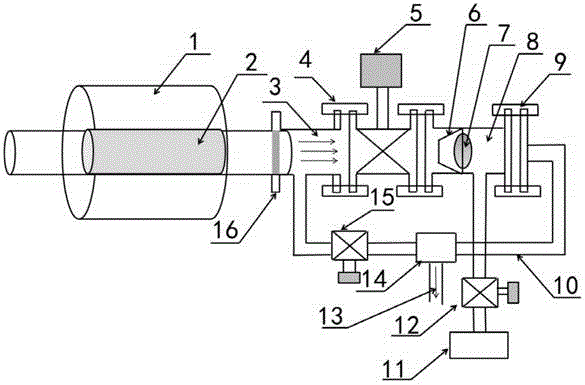

[0048] A horizontal chemical vapor deposition carbon nanotube growth furnace is adopted. The carrier gas flow rate of the chemical vapor deposition carbon nanotube growth furnace 1 is 2000ml / min. The film substrate is collected by filter paper, and the filter paper with a diameter of 50mm is placed in the film-forming collection fixture. 6, the edge of the filter paper is fixed by using the pressing sheet in the film-forming collection and fixing device 6, and after the film-forming and collecting and fixing device 6 is placed in a suitable position inside the pipeline of the film collecting chamber 8, the film-forming and collecting and fixing device 6 is clamped by the inside of the pipeline. slot fixed. First, open the ball valve switch 5, close the vacuum pump gas circuit switch 12 and the bypass gas circuit switch 15, and collect the single-walled carbon nanotube film; after the collection, close the ball valve switch 5, turn on the vacuum pump gas circuit switch 12 and th...

Embodiment 2

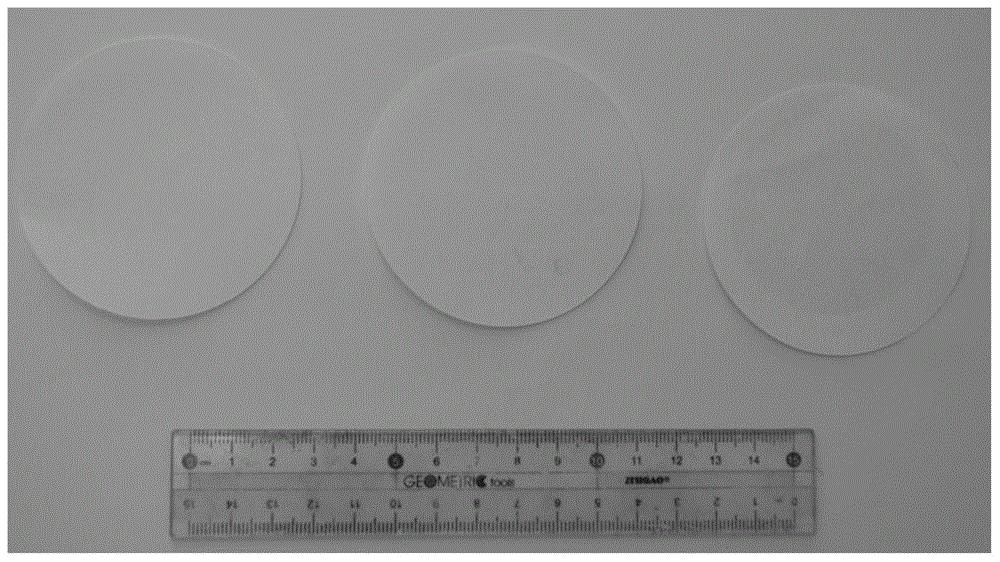

[0050] A vertical chemical vapor deposition carbon nanotube growth furnace is adopted. The carrier gas flow rate of the chemical vapor deposition carbon nanotube growth furnace 1 is 4000ml / min, and the film substrate is collected by a microporous filter membrane. The experimental steps of Example 1 were repeated, and the film samples whose growth time was 1 minute, 2 minutes, and 3 minutes were collected respectively, such as image 3 shown. Same as Example 1, the color of the film becomes darker with the increase of collection time, but all three films are very uniform.

Embodiment 3

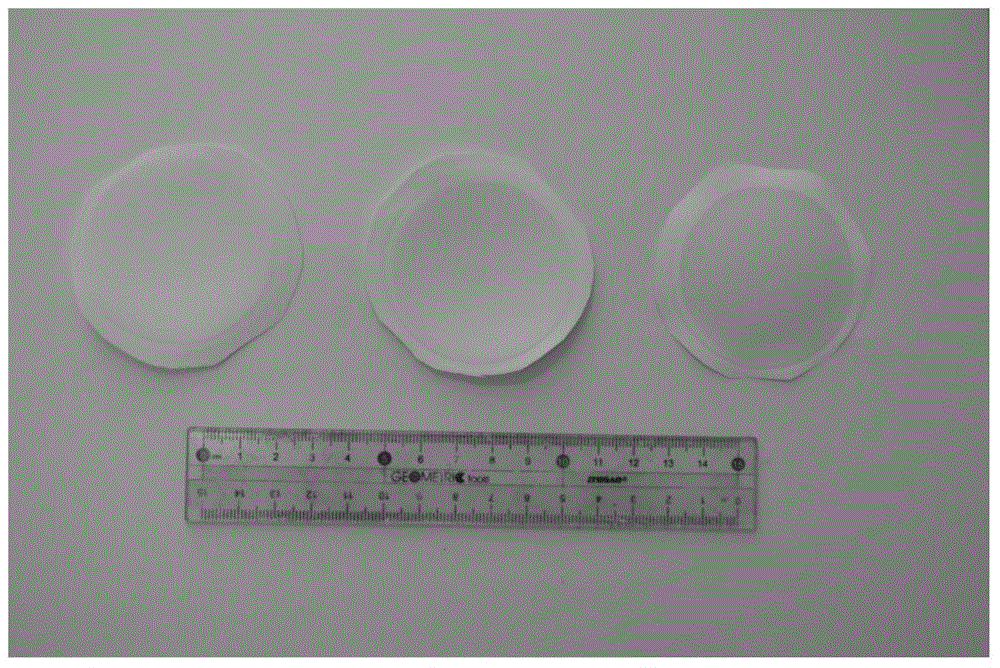

[0052] A vertical chemical vapor deposition carbon nanotube growth furnace was adopted, the carrier gas flow rate of the chemical vapor deposition carbon nanotube growth furnace 1 was 1000ml / min, and the film substrate was collected with aluminum foil. Repeat the experimental procedure of embodiment 1, collected the thin film sample that growth time is 1 minute, as Figure 4 shown. The aluminum foil loaded with the carbon nanotube film is darker in color (right) compared to the aluminum foil without the carbon nanotube film (left).

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com