Locking clamping track instrument

A rail clamp and locking technology, which is applied in the direction of travel mechanism, load hanging element, transportation and packaging, etc., can solve the problems of personal casualties of ground workers, easy slippage and deformation of the rail clamp, and overturning of the rail clamp. , to achieve the effect of increasing the contact area, simple and convenient installation and disassembly, and avoiding slippage and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

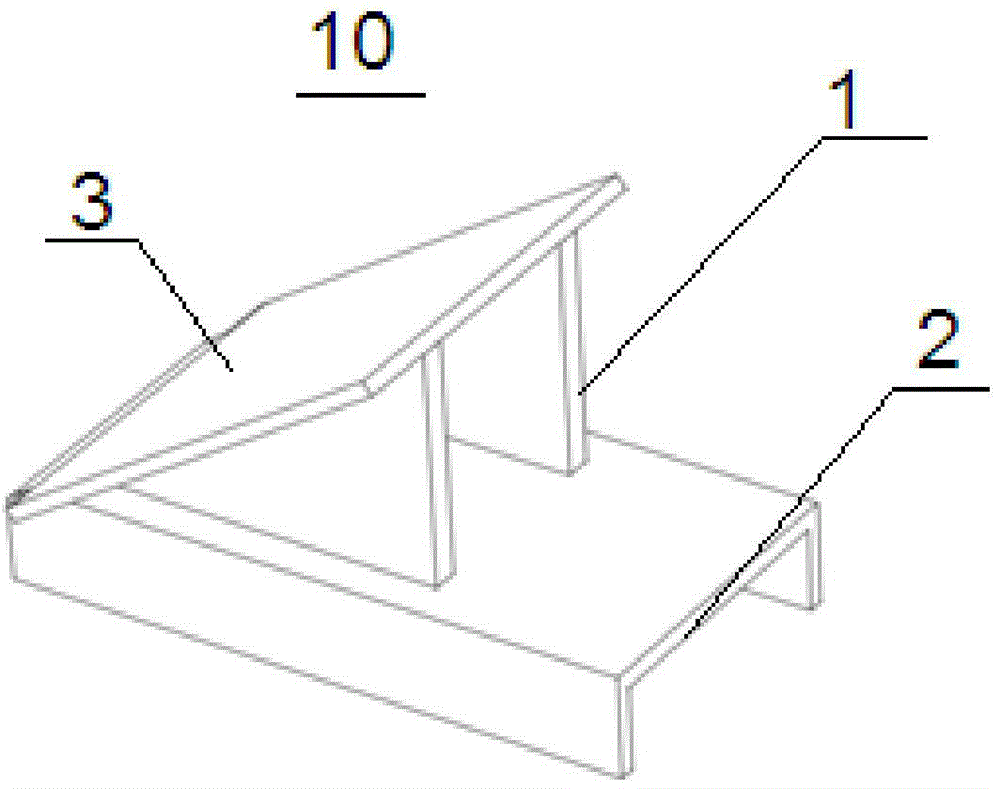

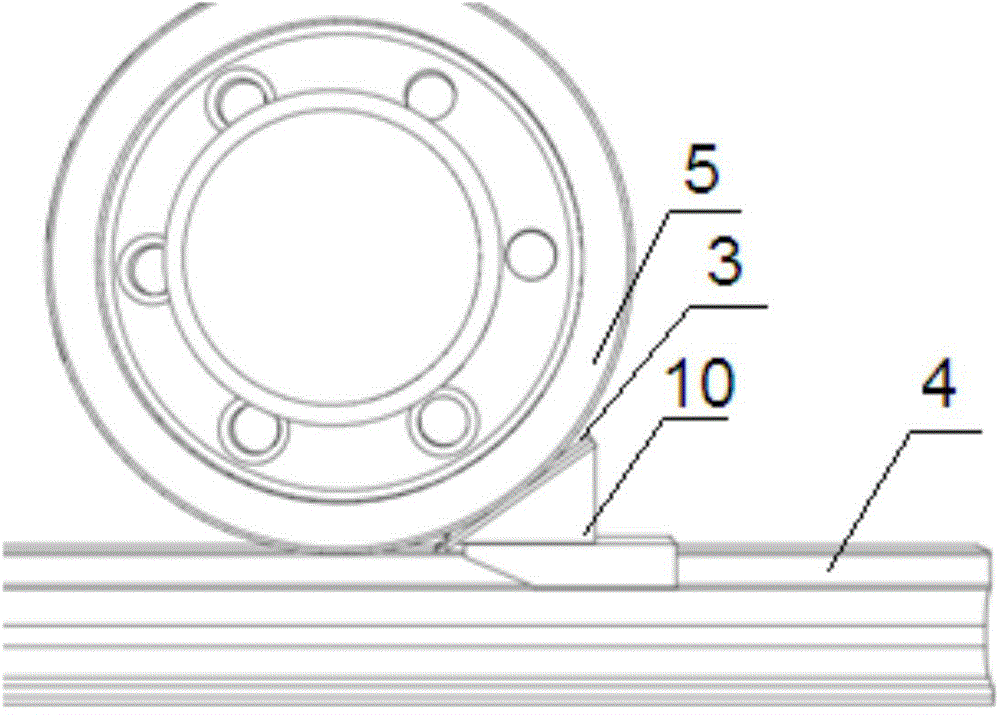

[0044]The following will further explain and describe the locking rail device of the present invention with reference to the accompanying drawings and specific embodiments, but the explanation and explanation do not constitute an improper limitation to the technical solution of the present invention.

[0045] image 3 The assembly structure of the locking rail device according to the present invention in one embodiment is shown, Figure 4 and Figure 5 Then the structures of the base and the handle in the locking rail device are respectively shown.

[0046] like image 3 , Figure 4 and Figure 5 As shown, the locking rail 20 includes: a base 21 with an inverted U-shaped cross section, which can be sleeved on the rail; an arc panel 22, which is fixed on the base 21, and the arc surface of the arc panel can be connected with the wheel The handle locking seat 23 is fixed on the base 21, and the handle locking seat 23 has a locking groove 231; When the handle 24 is locked, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com