Automated three-dimensional warehouse for placing round goods and goods incoming and outgoing method thereof

A three-dimensional warehouse and cargo technology, applied in storage devices, transportation and packaging, etc., can solve problems such as unstable operation, safety accidents, and rolling goods, and achieve the effects of not easy confusion, high efficiency in incoming and outgoing, and stable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

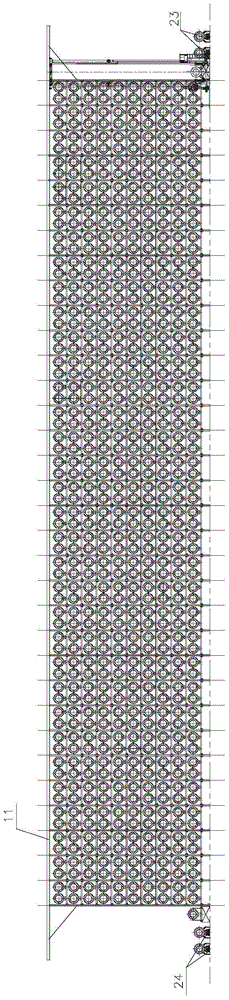

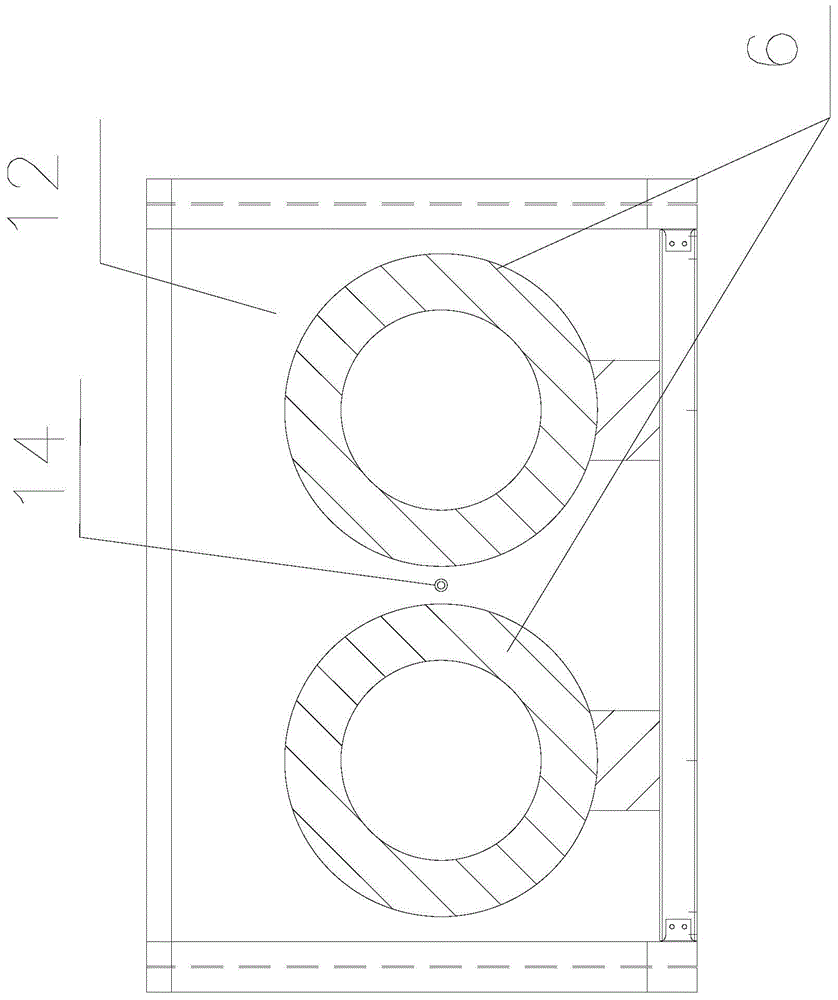

[0057] In order to achieve the purpose of the present invention, as Figure 1 to Figure 15 As shown, in one of the embodiments of the present invention, an automated three-dimensional warehouse for placing circular goods and its import and export method are provided for accessing steel coils 6 .

[0058] An automatic three-dimensional warehouse for placing round goods includes: a three-dimensional warehouse 1, a transport trolley 2, a stacker 3, a temporary storage device 4 and a warehouse-out device 5.

[0059] Such as Figure 1-4 As shown, the three-dimensional warehouse 1 includes four rows of shelves 11, and the shelves 11 include columns and beams. The columns and beams are made of H-shaped steel, which has good strength and is easy to manufacture. The shelf 11 adopts the on-site bolt connection method, which is convenient for material t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com