Unordered automatic pipe grabbing and inserting manipulator for small U-shaped pipes of fin assembly

A U-shaped tube and manipulator technology, applied in manipulators, metal processing, metal processing equipment and other directions, can solve the problems of high labor intensity of operators, stop work waiting for materials, low equipment utilization rate, etc., to achieve a high degree of equipment automation and ensure products. The effect of high quality and equipment utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

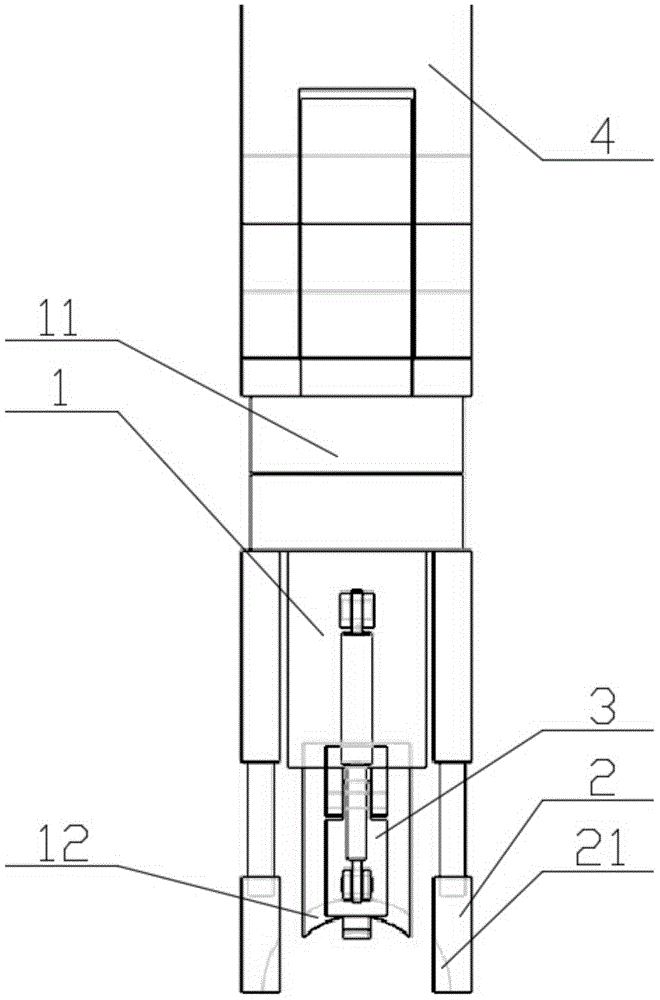

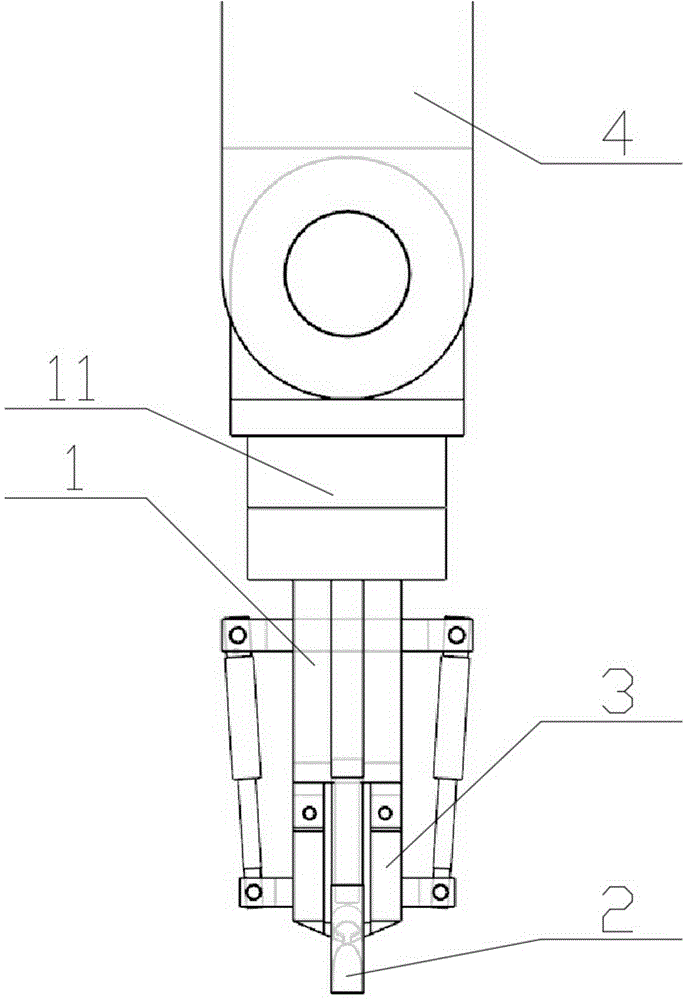

[0025] like Figure 1 to Figure 3 As shown, the small U-shaped tube of the fin assembly disorderly automatically grabs and intubates the manipulator including the main body 1, the gripping finger 2 and the holding finger 3 (the following descriptions take the left and right horizontal directions as X coordinates, and the front and rear horizontal directions as Y Coordinates, take the vertical direction as the Z coordinate, take the direction of rotation along the left and right horizontal axes as the rotation axis as the A coordinate, take the direction of rotation along the front and rear horizontal axes as the rotation axis as the B coordinate, and take the direction of rotation along the vertical axis as the rotation axis direction is the C coordinate).

[0026] The top of the body 1 is connected to the end of the mechanical arm 4 with an X-coordinate drive mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com