Simple taper shank puller

A tapered handle, simple technology, applied in the field of mechanical processing tools, can solve the problems of low efficiency, easily damaged equipment, difficult to disassemble, etc., and achieve the effect of high efficiency, convenient production and convenient selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

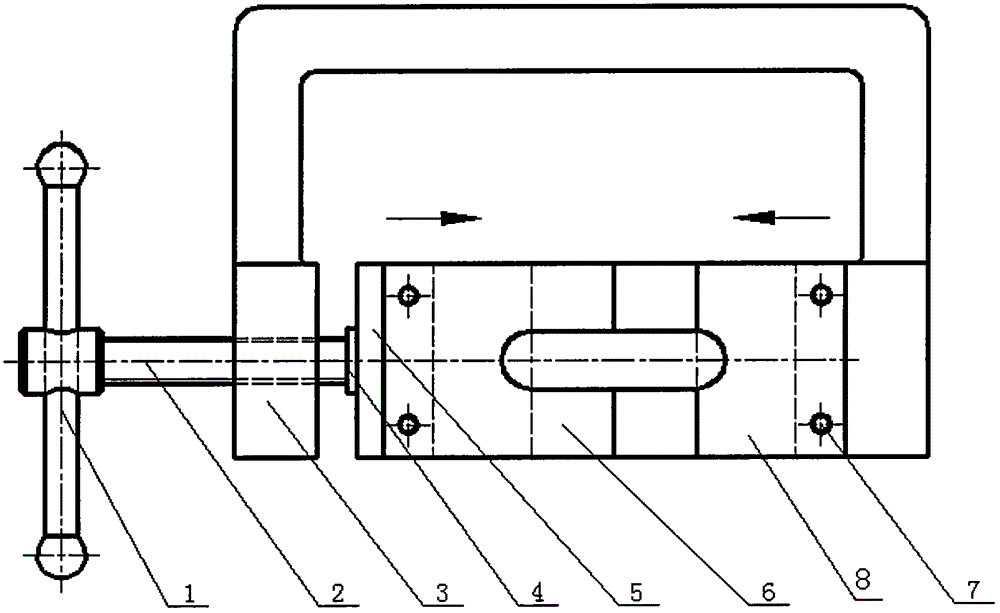

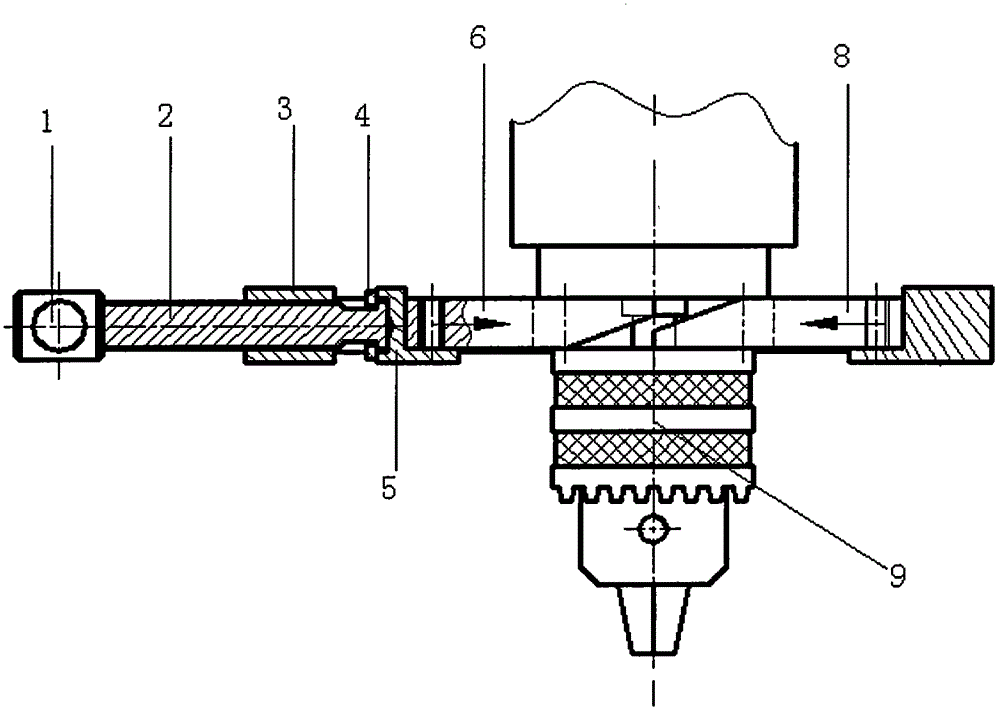

[0010] exist figure 1 , figure 2 In the shown embodiment, a stirring rod (1), a screw rod (2), a support frame (3), a pressing plate (4), a supporting plate (5), a left wedge (6), a cylindrical pin (7), a right Wedge (8), drill chuck (9).

[0011] Implement the simple and easy tapered shank puller of the present invention, comprise bracing frame (3), bracing frame (3) left part installs screw rod (2), screw rod (2) left end fixes stirring rod (1), screw rod (2) left end fixes pressing plate ( 4), the pressure plate (4) is connected to the supporting plate (5), the supporting plate (5) fixes the left wedge (6) with a cylindrical pin (7), and the right wedge (6) is fixed with a cylindrical pin (7) on the right part of the support frame (3) (8). There are U-shaped grooves on the left wedge (6) and the right wedge (8), and the cross-sections of the left wedge (6) and the right wedge (8) are inclined planes with a slope of 1:4 to 1:5 between. A drill chuck (9) is built-in in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com