Improved drilling die

A technology for drilling dies and pressing plates, applied in the field of tooling and fixtures, can solve problems such as affecting the assembly of other parts, affecting the operability of products, and difficult processing operations, and achieving the effects of extending the service life, preventing fluff, and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

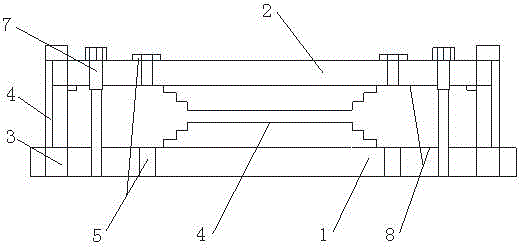

[0019] Such as figure 1 As shown, an improved drilling mold of the present invention includes a base 1 and a pressing plate 2 arranged in parallel on the base 1 and having a certain distance from the base 1. The left and right sides of the pressing plate 2 are connected to the base 1 through fixing rods 3. The fixed rod 3 is provided with a groove 4 for the displacement of the pressure plate 2, and a plurality of through holes 5 penetrating the upper and lower surfaces of the pressure plate 2 and the base 1 are opened on the corresponding positions of the pressure plate 2 and the base 1. The lower surface of the pressure plate 2 and the base 1 The alignment position of the upper surface is provided with a positioning boss 6 suitable for the inner hole of the workpiece to be processed.

[0020] Preferably, as an embodiment, the improved drilling mold of the present invention further includes fasteners 7 for fixing the workpiece to be processed between the base 1 and the pressin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com