Double-station horizontal core shooting device

A double-station, horizontal technology, applied in the direction of manufacturing tools, metal processing equipment, casting molding equipment, etc., can solve the problem of reducing the work efficiency of staff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

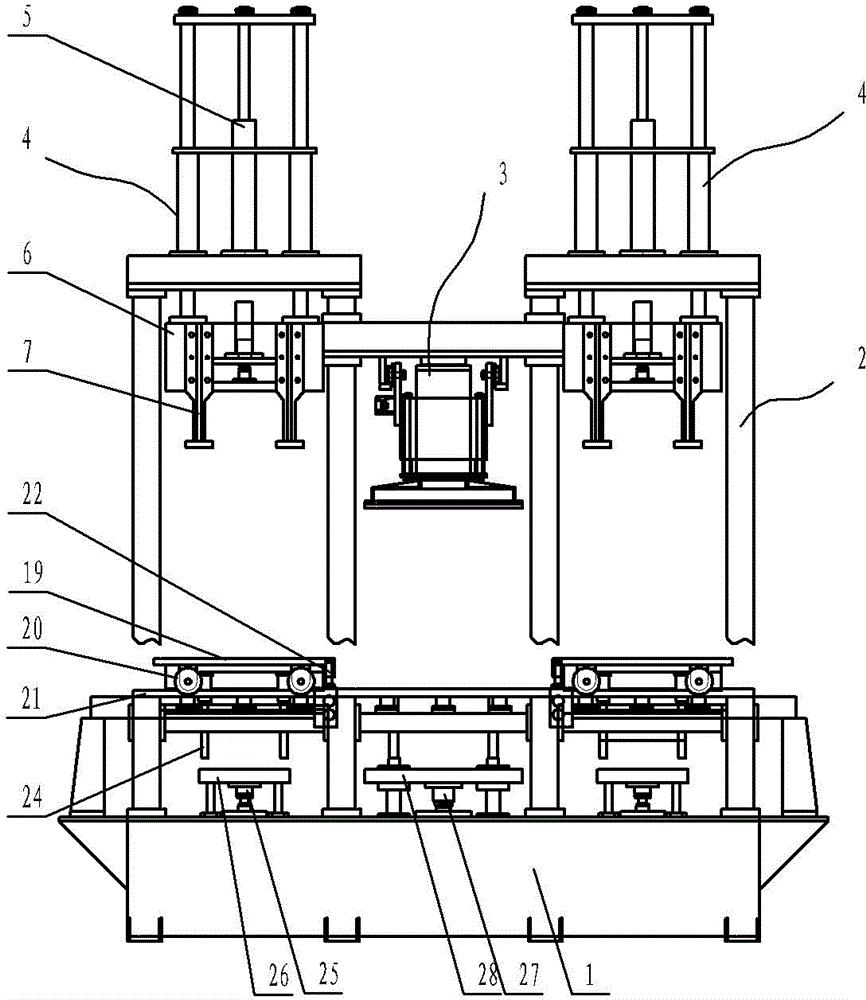

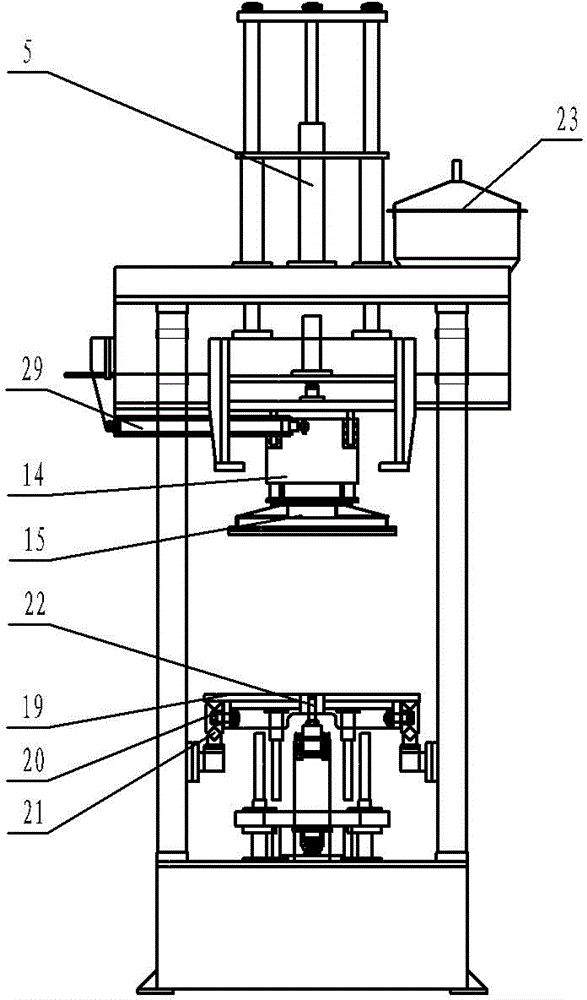

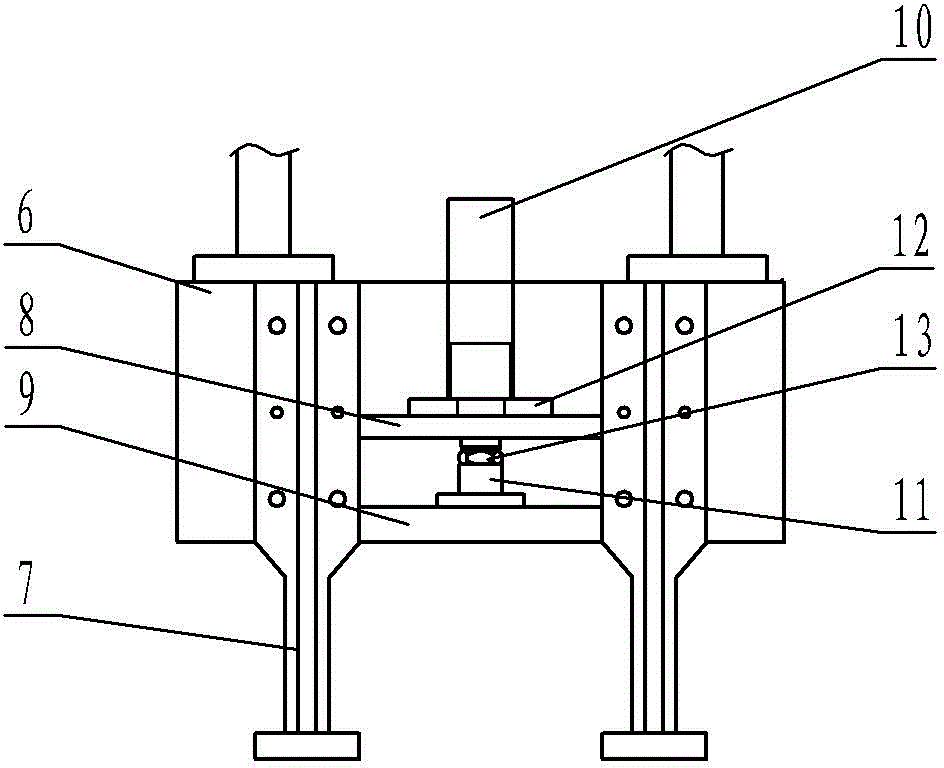

[0015] Such as Figure 1 to Figure 4 As shown, the double-station horizontal core shooting device includes a frame 2 and a base 1. The frame 2 is provided with a sand shooting mechanism 3 and a mold clamping mechanism 4. Both sides of the mechanism 3 are located in the connecting direction of the two combined mold mechanisms 4. The base 1 is provided with a guide rail 21, which also includes two sets of workbenches 19 and two sets of positioning mechanisms 22. The workbench 19 is arranged on the guide rail 1 21. , and be provided with the roller 20 that is rollingly connected with guide rail one 21, the positioning hole that cooperates with positioning mechanism is provided on the workbench, and positioning mechanism is installed on the base 1.

[0016] The sand-shooting forming mechanism 3 includes a sand-filling funnel 23, a shooting head 15 and a sand cylinder 14. Hanging feet 16 are respectively arranged on both sides of the upper end of the sand cylinder 14. The top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com