Full-automatic penholder flocking machine and flocking process thereof

A fully automatic, flocking machine technology, applied in the direction of penholders, printing, writing utensils, etc., to achieve the effect of convenient use, reduced labor costs, and reduced material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing:

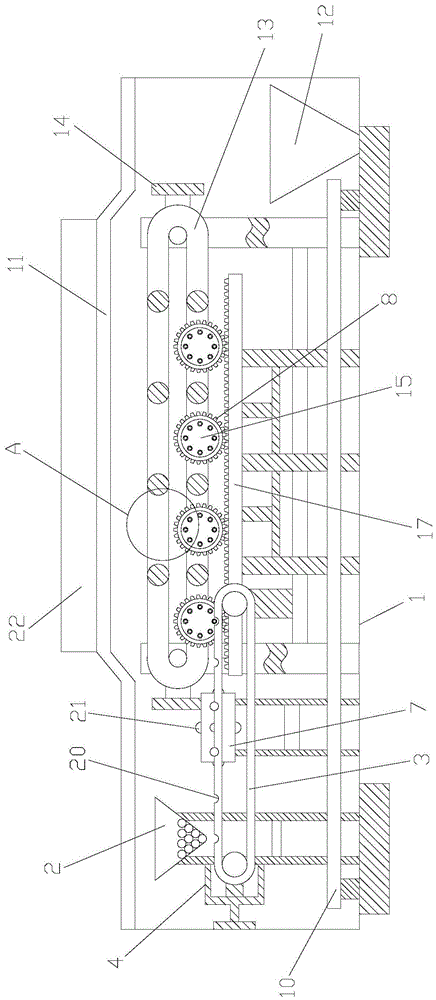

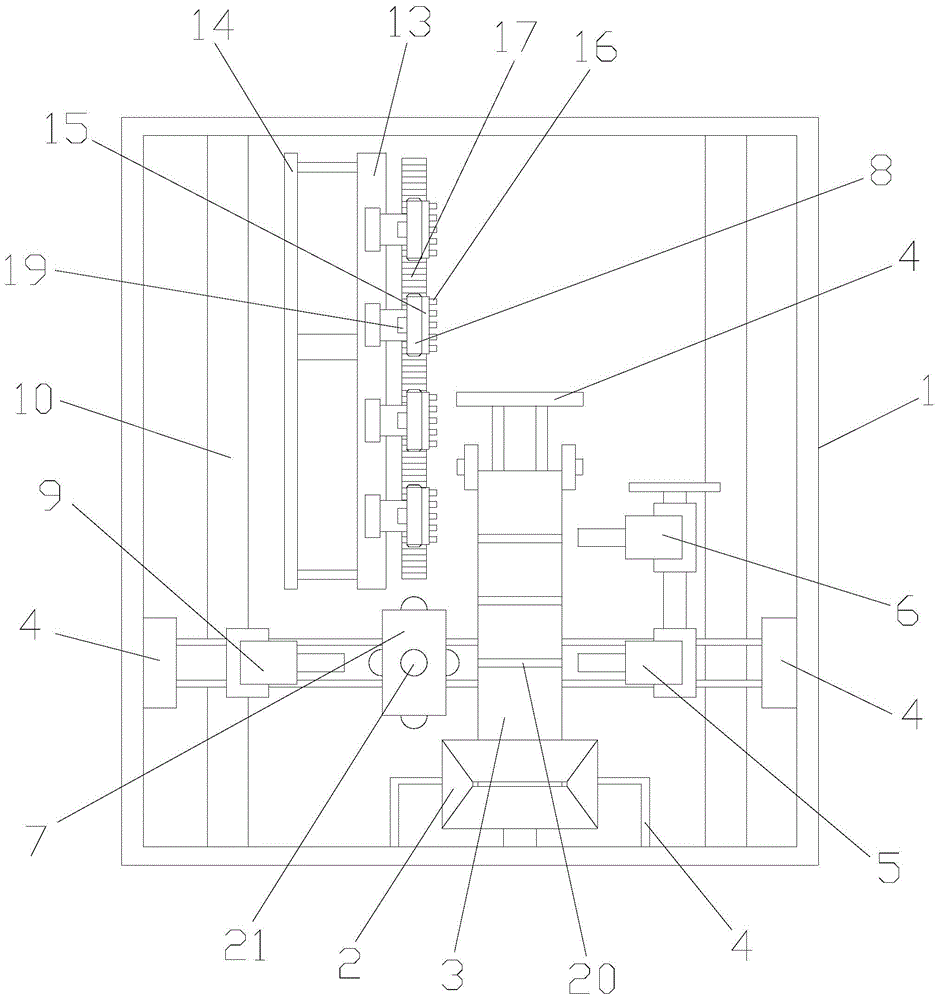

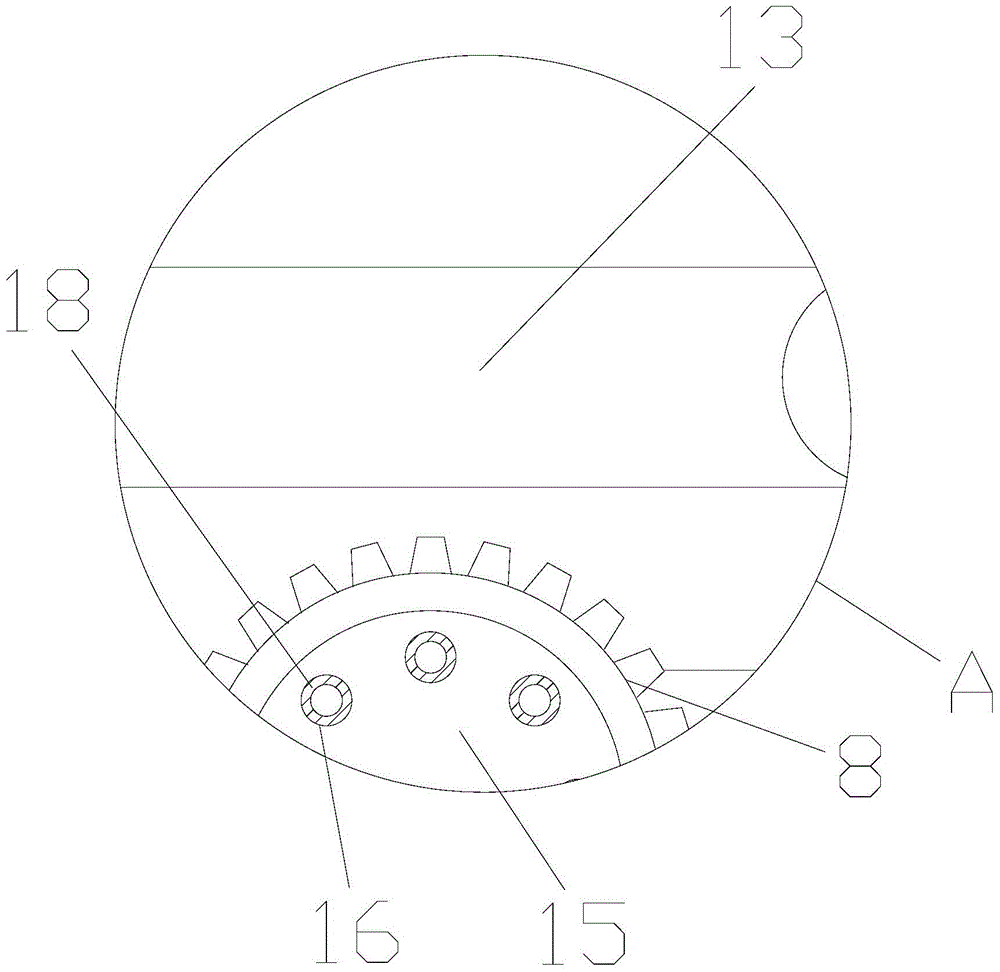

[0029] With reference to accompanying drawing: this fully automatic pen holder flocking machine in the present embodiment comprises a casing 1, and one end in casing 1 is provided with discharge hopper 2, and discharge hopper 2 is installed on the casing 1, and the discharge hopper 2 There is a conveyor belt 3 at the exit, and a bracket 4 is fixed inside the box body 1. The conveyor belt 3 is installed on the bracket 4. The right side of the middle part of the conveyor belt 3 is provided with a first cylinder 5 and a second cylinder 6 in turn. The middle part of the conveyor belt 3 Spraying box 7 and a group of gears 8 are arranged in sequence on the left side of the left side of the machine. The first cylinder 5, the second cylinder 6, and the spraying box 7 are all installed on the bracket 4. The first cylinder 5 and the spraying box 7 are arranged symmetrically, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com