A kind of canned oyster with low purine and preparation method thereof

A technology for oysters and purines, which is applied in the field of low-purine canned oysters and their preparation, can solve the problem of high purine content, and achieve the effects of low purine content and meeting high-level demands.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

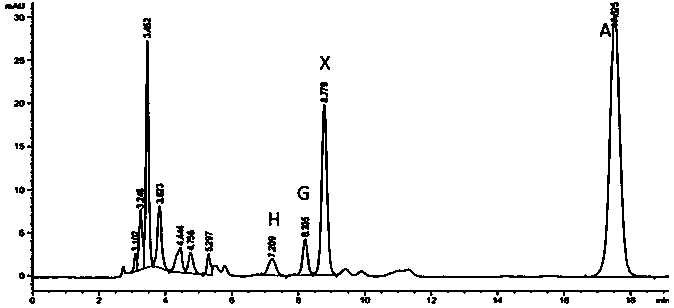

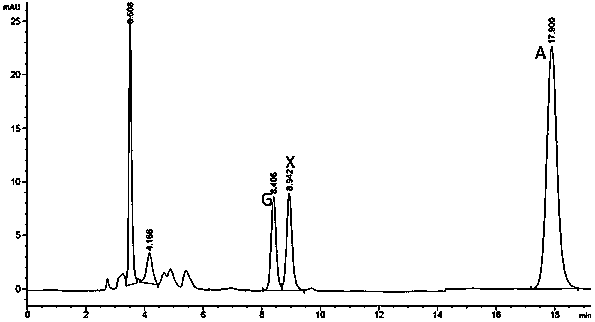

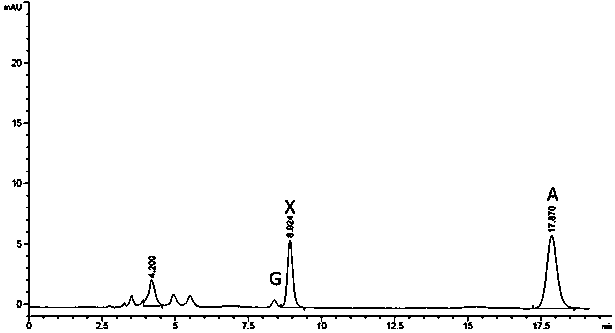

Image

Examples

Embodiment 1

[0027] 1. Shell the fresh oysters and wash the sediment;

[0028] 2. Soak the oysters in vinegar with an acidity of 2.0 mg / mL for 30 minutes;

[0029] 3. Boil oysters and vinegar for 10 minutes;

[0030] 4. Rinse the cooked oysters with clean water and put them in cans;

[0031] 5. Sauce adjustment: Heat 5 parts by mass of peanut oil to 140°C, add 0.5 parts by mass of shallots, 1 part by mass of garlic, and 1 part by mass of ginger and stir-fry until fragrant, add 30 parts by mass of soy sauce, 0.5 parts by mass of star anise and 5 parts by mass of star anise Parts by mass of white sugar and simmer on low heat until the soup is thick;

[0032] 6. Pour the adjusted sauce into the tank and seal it with air;

[0033] 7. Sterilize the tank under the conditions of 100°C, 20 min, and 0.1 MPa to obtain low-purine canned oysters.

Embodiment 2

[0035] 1. Shell the fresh oysters and wash the sediment;

[0036] 2. Soak oysters in hydrochloric acid solution with an acidity of 3.0 mg / mL for 30 min;

[0037] 3. Boil the oysters together with the hydrochloric acid solution for 5 minutes;

[0038] 4. Rinse the cooked oysters with clean water and put them in cans;

[0039] 5. Sauce adjustment: Heat 7 parts by mass of olive oil to 150°C, add 1 part by mass of green onion, 1 part by mass of garlic, and 1 part by mass of ginger, stir-fry until fragrant, add 40 parts by mass of soy sauce, 1 part by mass of star anise and 6 parts by mass of white sugar and simmer on low heat until the soup is thick;

[0040] 6. Pour the adjusted sauce into the tank and seal it with air;

[0041] 7. Use the conditions of 120°C, 20 min, and 0.2 MPa to sterilize the can to obtain low-purine canned oysters.

Embodiment 3

[0043] 1. Shell the fresh oysters and wash the sediment;

[0044] 2. Soak the oysters in a tartaric acid solution with an acidity of 4.0 mg / mL for 35 minutes;

[0045] 3. Boil oysters together with tartaric acid solution for 6 minutes;

[0046] 4. Rinse the cooked oysters with clean water and put them in cans;

[0047] 5. Sauce adjustment: Heat 8 parts by mass of rapeseed oil to 150°C, add 0.5 parts by mass of green onions, 1 part by mass of garlic, and 1 part by mass of ginger, stir-fry until fragrant, add 35 parts by mass of soy sauce, and 1 part by mass of star anise and 5 parts by mass of white sugar and cook slowly until the soup is thick;

[0048] 6. Pour the adjusted sauce into the tank and seal it with air;

[0049] 7. Use the conditions of 100°C, 30 min, and 0.15Mpa to sterilize the can to obtain low-purine canned oysters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com