Cutting insert and cutting edge replacement-type rotating cutting instrument

A technology for cutting blades and blades, which is applied in the direction of milling cutting blades, manufacturing tools, milling cutters, etc., and can solve problems such as high-frequency vibration, insufficient overall strength, and thin cutting blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

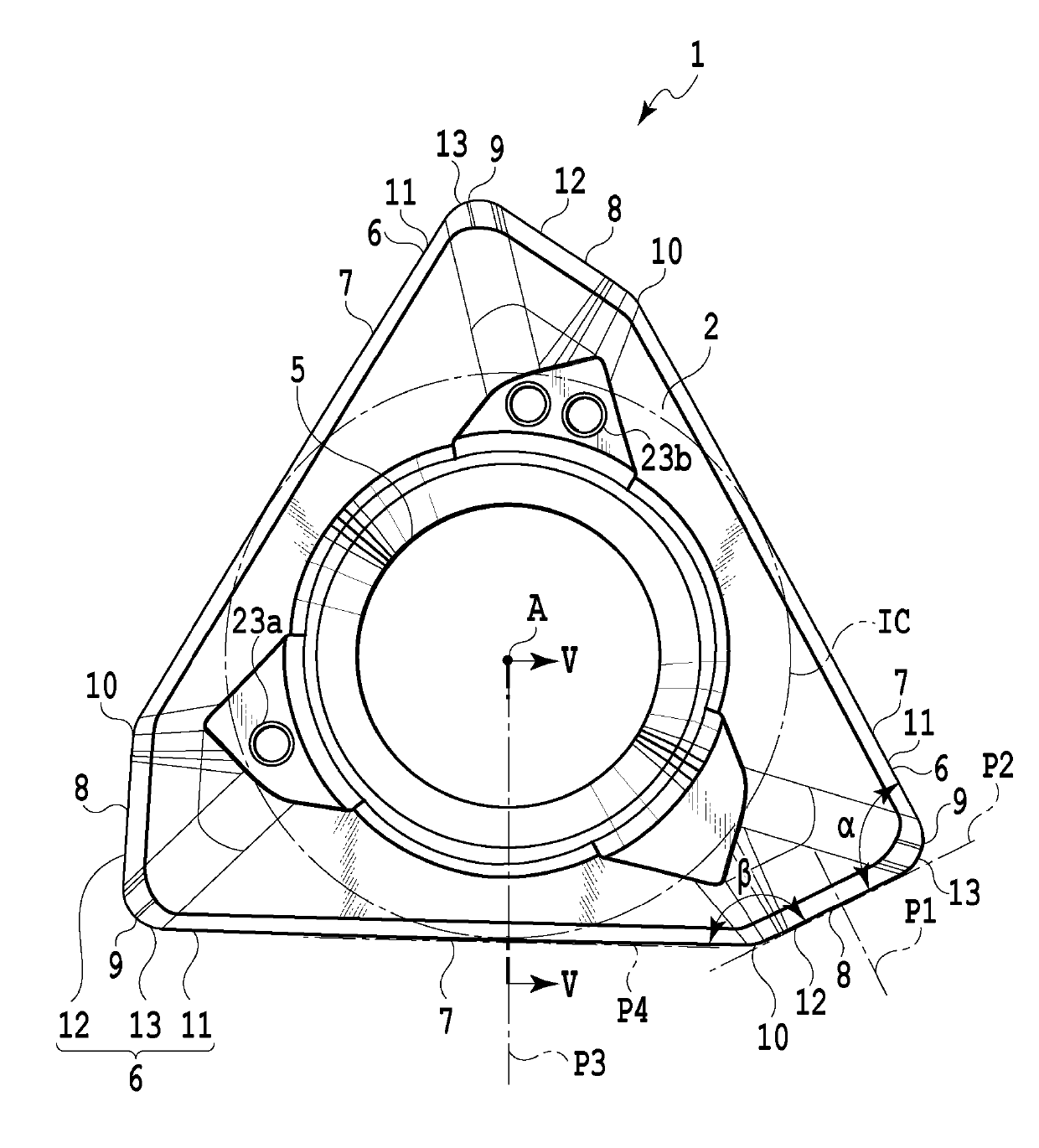

[0039] The cutting insert 1 of the present embodiment is as Figures 1 to 4 As shown, there are two end faces 2, 3 which are opposite or face opposite sides of each other, and a peripheral side 4 which connects them or extends between them. Below, will figure 1 as well as figure 2 One end surface (corresponding to the first end surface of the present invention) 2 facing upward is referred to as the upper surface, and the other end surface (corresponding to the second end surface of the present invention) 3 is referred to as the lower surface. In addition, based on the relative positional relationship between the upper surface and the lower surface, the words "upper" and "lower" may be used in the following description. However, these terms are not intended to limit the orientation or position of the cutting insert, but are used to facilitate understanding,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com