Battery tab connection device and method

A connection device and tab technology, which is applied in the field of lithium ion cell tab connection devices, can solve problems such as poor welding, failure, and soldering pollution, and achieve the effects of preventing tin from turning into ash, preventing offset, and protecting the environment

Active Publication Date: 2017-09-15

骆驼集团蓄电池研究院有限公司

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the traditional process, the connection method of lithium-ion battery tabs is usually soldering. With the development of science and technology, the shortcomings of soldering are gradually exposed: first, soldering will produce pollution, due to the smoke generated during the soldering process It will cause harm to the human body and the environment. In Europe, the protection of welding workers and the protection of the environment have been enforced in the form of legislation. Welding without any protective measures is not allowed; secondly, the characteristics of tin are not Suitable for connecting battery lugs, there are 3 allotropes of tin, namely white tin, gray tin and brittle tin

When the temperature drops below 13.2 degrees Celsius, the volume of white tin suddenly expands, and the space between atoms increases, so it becomes another crystalline form of gray tin. If the temperature drops sharply to minus 33 degrees Celsius, it will produce " Tin plague", that is, crystal tin will turn into powder tin. In most parts of northern my country, the outdoor temperature is very low in winter, and the welding of battery tabs is very easy to fail at this temperature; again, tin welding is harmful to workers. The technical requirements are relatively high, and the welding workers must be specially trained workers. Once the operation is wrong, it is very easy to have missing welding, virtual welding, poor welding, etc., and there will be hidden dangers in the connection of the battery tabs, or even failure.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

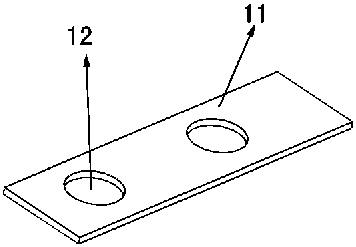

A device and method for connecting battery tabs, including a series-parallel board, and a connecting piece that cooperates with the series-parallel board to compress the battery tabs; There is a cross-shaped rib on the upper surface of the parallel board, and the cross-shaped rib divides the upper surface of the parallel board into four rectangular lug accommodation units; each lug accommodation unit is provided with a thin strip lug leading out near the retaining bar. holes; each lug accommodation unit is provided with a threaded hole for connecting the connecting piece and the lug; the connecting piece is provided with a protrusion corresponding to the rib on the parallel board, and the connecting piece on both sides of the protrusion is respectively connected to the string. Mounting holes for fixing parallel boards; also includes edge pressing parts for pressing tabs; edge pressing parts have connection holes fixed with series and parallel boards; series and parallel boards are made of insulating materials; connectors, edge pressing Fasteners are conductors. The invention can well complete the series-parallel connection of the electric cores, and the connection is firm, which fundamentally eliminates the hidden dangers of tin turning into ashes and connection failure in a low-temperature environment.

Description

Battery tab connection device and method technical field The invention belongs to the technical field of flexible packaging lithium-ion batteries, and in particular relates to a lithium-ion battery tab connection device that replaces traditional soldering. Background technique In the traditional process, the connection method of lithium-ion battery tabs is usually soldering. With the development of science and technology, the shortcomings of soldering are gradually exposed: first, soldering will produce pollution, due to the smoke generated during the soldering process It will cause harm to the human body and the environment. In Europe, the protection of welding workers and the protection of the environment have been enforced in the form of legislation. Welding without any protective measures is not allowed; secondly, the characteristics of tin are not It is suitable for connecting the tabs of the battery core. There are 3 allotropes of tin, namely white tin, gray tin and ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01M2/26H01M50/54

CPCH01M10/0525H01M50/54Y02E60/10

Inventor 张郁茹刘勇夏嘉岱

Owner 骆驼集团蓄电池研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com