Material testing machine measurement and control system

A material testing machine, measurement and control system technology, applied in the direction of analyzing materials, measuring devices, instruments, etc., can solve the problems of poor system scalability and mobility, cumbersome system wiring, high investment and maintenance costs, and achieve simple and efficient circuits. Solve the cumbersome wiring and good real-time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

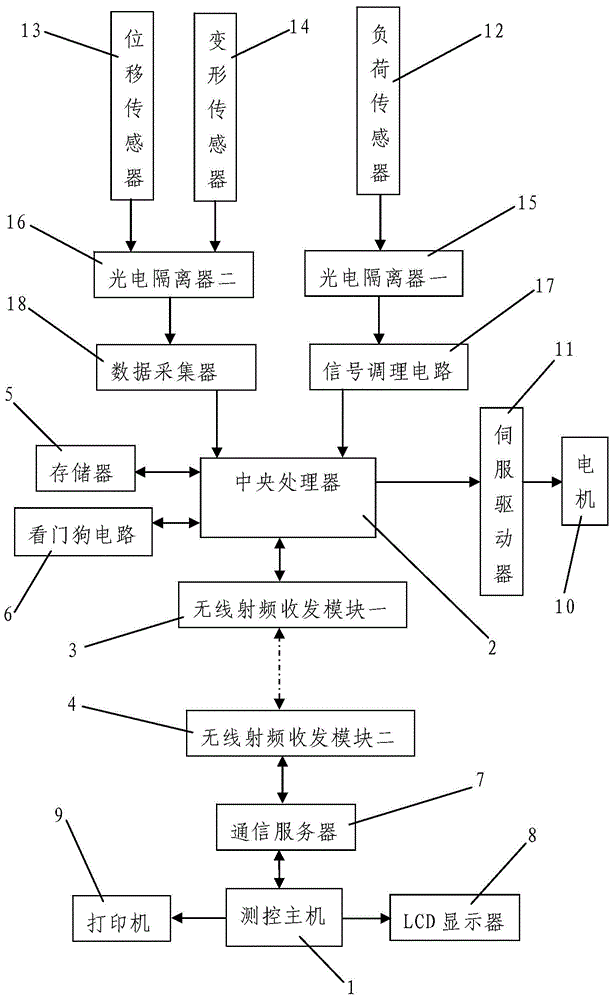

[0022] Such as figure 1 As shown, the present invention includes a measurement and control host 1, a central processing unit 2, a radio frequency transceiver module 1 3, a radio frequency transceiver module 2 4, a photoelectric isolator 15, a photoelectric isolator 2 16, and is used to detect relevant operating parameters of a material testing machine The sensor unit, the memory 5 and the watchdog circuit 6 connected with the central processing unit 2 and the communication server 7, the LCD display 8 and the printer 9 connected with the measurement and control host 1; the central processing unit 2 and the communication server 7 are respectively Connect with the radio frequency transceiver module one 3 and the radio frequency transceiver module two 4, the radio frequency transceiver module one 3 and the radio frequency transceiver module two 4 are wirelessly connected, the material testing machine includes a base, a specimen fixture, a leading screw , a crossbeam and a motor 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com