High-speed structured light three-dimensional surface shape vertical measurement method

A three-dimensional surface, vertical measurement technology, applied in measurement devices, optical devices, instruments, etc., can solve the problems of complex measurement system, slow measurement speed, frequency domain spectrum aliasing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings, working principles and embodiments.

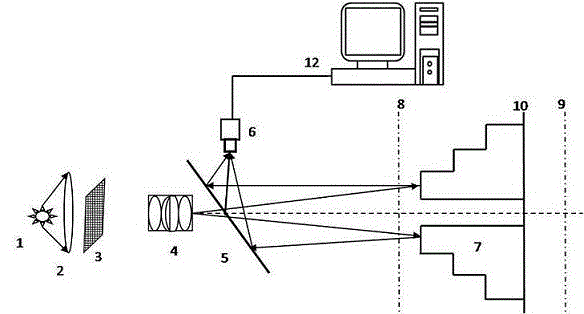

[0021] The principle diagram of the present invention is as figure 1 As shown, Figure (a) is the schematic diagram for establishing height mapping: 1 is the projection lighting source, 2 is the condenser lens, 3 is the orthogonal grating carrier, 4 is a special projection lens composed of an ordinary projection lens and a cylindrical lens , 5 is a half-mirror, 6 is a camera, 8 is the start position plane of scanning, 9 is the end position plane of scanning measurement area, and 11 is a translation platform; Figure (b) is the principle diagram when measuring an object: 7 is the object to be measured, and 10 is the reference plane when measuring.

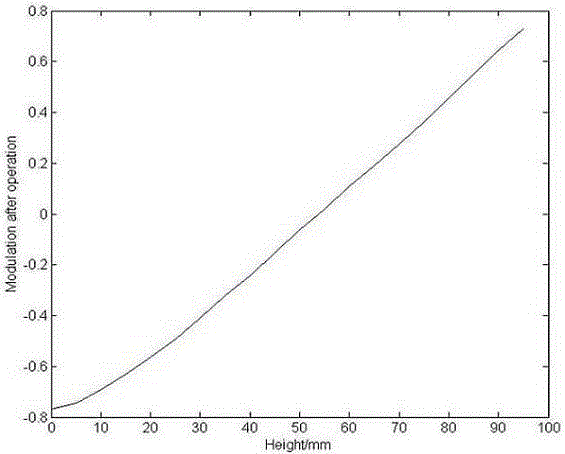

[0022] Under the paraxial approximation of geometric optics, a sinusoidal grating is placed at the position of the object plane of the projection lens. Considering the ideal imagi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com