Vibrating Suction Bucket Foundation Leveling Device

A barrel-shaped foundation and leveling device technology, applied in infrastructure engineering, construction and other directions, can solve the problems of low control accuracy, inclination of suction barrel-shaped foundations, and high requirements for barrel-shaped basic structures, so as to weaken frictional resistance and improve The effect of deep penetration and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

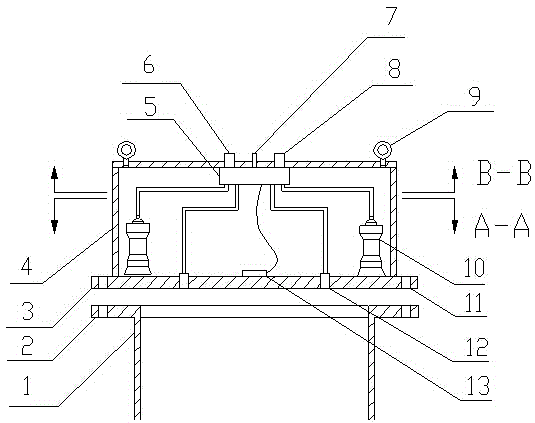

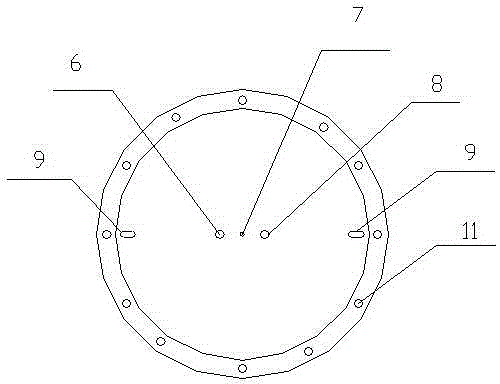

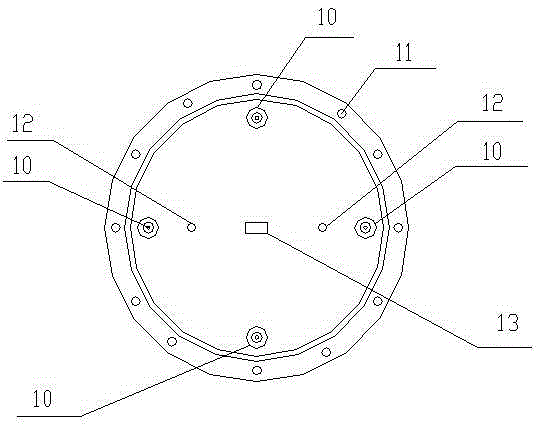

[0023] Such as Figure 1 to Figure 5 As shown, the present invention comprises base plate 3, bung 4, vibrating mechanism 10, two-way angle sensor 13 and electromagnetic valve control module 5; Base plate 3 is covered with bung 4, is positioned at base plate 3 in bung 4 and is evenly distributed on the same circumference There are a plurality of vibrating mechanisms 10, and two base plate negative pressure ports 12 are opened on the base plate 3 located in the plurality of vibrating mechanisms 10, and a bidirectional angle sensor 13 is installed in the center of the base plate; 7 and bung cover negative pressure port 8, positive pressure port 6 are respectively connected with a plurality of electromagnetic valve 16 input ports in the electromagnetic valve control module 5, and a plurality of electromagnetic valve 16 output ports are respectively connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com