A kind of waterborne fluorocarbon coating and preparation method thereof

A water-based fluorocarbon and water-based fluorocarbon emulsion technology, applied in the field of coatings, can solve the problems of human body and environmental toxicity, no ozone resistance, poor product stability, etc., and achieve the effects of simple operation, improved ozone resistance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

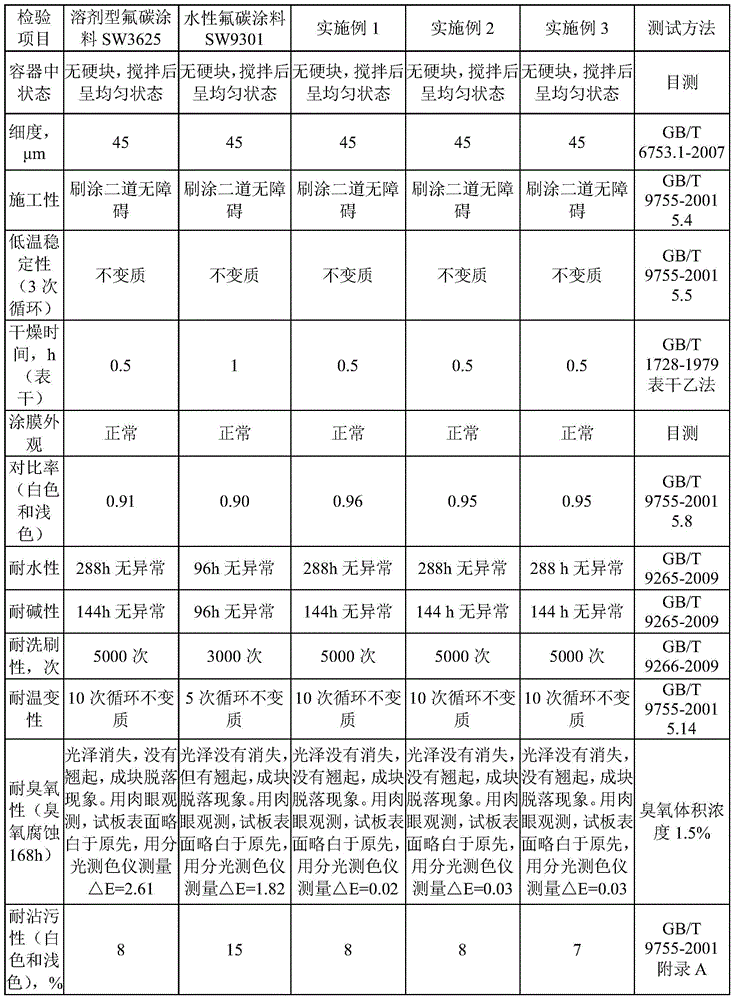

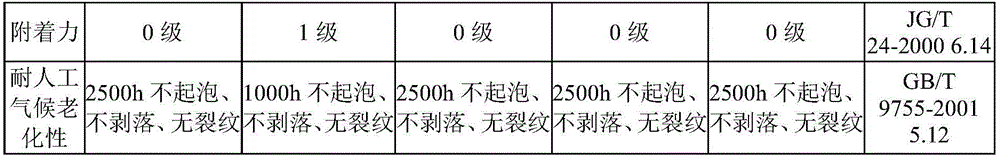

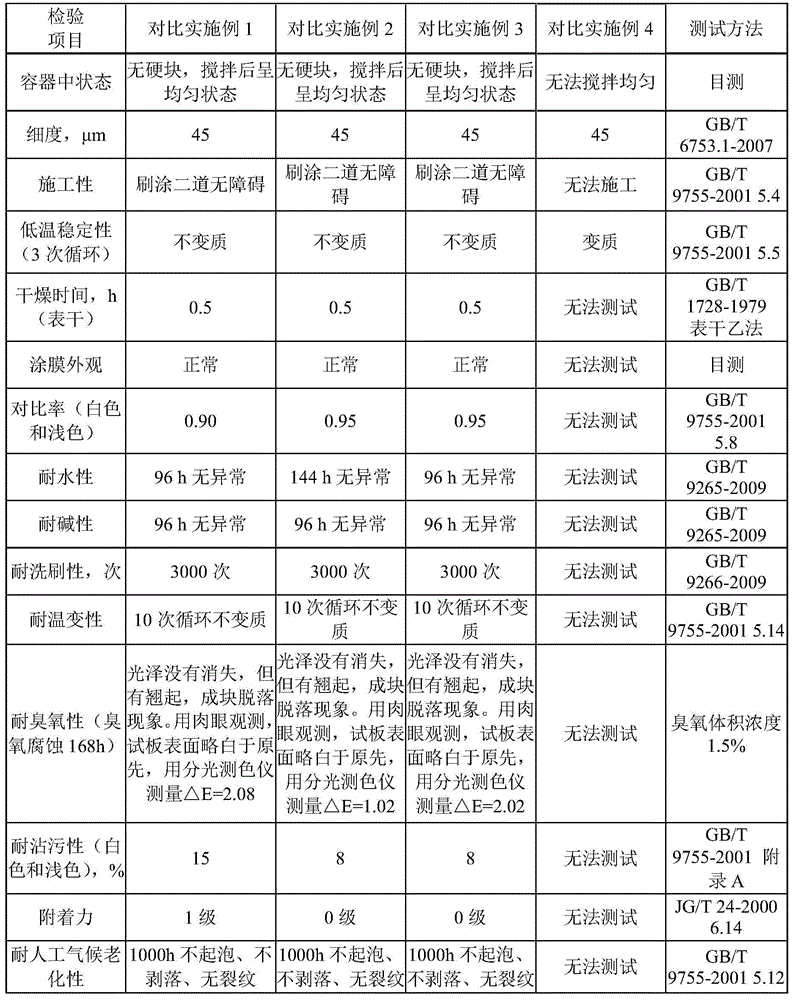

Examples

Embodiment 1

[0068] The raw material formula (wt%) of the ozone-resistant waterborne fluorocarbon coating is shown in Table 1 below.

[0069] The raw material formula (wt%) of the ozone-resistant waterborne fluorocarbon coating of table 1 embodiment 1

[0070] Water-based fluorocarbon emulsion HK8333-45 16.0% Hydroxyethyl cellulose HS30000YP2 3.2% Pigment: rutile titanium dioxide R996 19.0% Filler: heavy calcium carbonate CC-1250 23.0% Filler: calcined kaolin MXK201 8.0% High purity ozone resistant agent BHEB 3.0%

[0071] Wetting and dispersing agent WA200Rhodia 2.2% Multifunctional additive AMP-95 0.9% Defoamer RH-900 0.6% Thickener R278 3.3% MIRECIDE-KW / 600 fungicide 0.4% Coalescent Texanol 0.5% Antifreeze Propylene Glycol 4.0% Deionized water 15.9%

[0072] The preparation method of ozone-resistant water-based fluorocarbon coating is as follows:

[0073] (1) Stir hydroxyethyl cellulose...

Embodiment 2

[0077] The raw material formula (wt%) of the ozone-resistant waterborne fluorocarbon coating is shown in Table 2 below.

[0078] The raw material formula (wt%) of the ozone-resistant waterborne fluorocarbon coating of table 2 embodiment 2

[0079] Water-based fluorocarbon emulsion 4303 48.4% Hydroxyethyl Cellulose 250HBR 1.2% Pigment: carbon black M1300 10.7% Filler: sericite powder GA-4 17.2% Liquid Ozone Resistant Agent AO-30 3.0%

[0080] Wetting and dispersing agent CF-10 0.5% Multifunctional additive AMP-95 0.4% Defoamer BD-405 0.2% Thickener R278 0.3% MIRECIDE-KW / 600 fungicide 0.4% Coalescent Texanol 2.9% antifreeze glycol 0.9% Deionized water 13.9%

[0081] The preparation method of ozone-resistant water-based fluorocarbon coating is as follows:

[0082] (1) Stir hydroxyethyl cellulose and 25.0wt% deionized water at a speed of 1100rpm, mix and dissolve to obtain solution A; ...

Embodiment 3

[0086] The raw material formula (wt%) of the ozone-resistant waterborne fluorocarbon coating is shown in Table 3 below.

[0087] The raw material formula (wt%) of the ozone-resistant waterborne fluorocarbon coating of table 3 embodiment 3

[0088] Water-based fluorocarbon emulsion CYWF-1128Y 34.0% Hydroxyethyl Cellulose HS100000YP2 1.3% Pigment: Cobalt Green (P.G.50) 10.7% Filler: calcined kaolin BM V60 10.1% Filler: sericite powder GA-4 11.1%

[0089] Anti-ozone agent MEC-75 4.5% Wetting and dispersing agent X-405 0.7% Multifunctional additive AMP-95 0.4% Defoamer BD-109 0.3% Thickener R278 1.1% MIRECIDE-KW / 600 fungicide 4.0% Coalescent Texanol 1.1% Antifreeze Propylene Glycol 0.8% Deionized water 19.9%

[0090] The preparation method of ozone-resistant water-based fluorocarbon coating is as follows:

[0091] (1) Stir hydroxyethyl cellulose and 30.0wt% deionized water at a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| minimum film forming temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| cloud point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com