A kind of method utilizing ferulic acid to regulate and prepare calcium carbonate crystal particles

A technology of ferulic acid and calcium carbonate, applied in the directions of calcium carbonate/strontium/barium, chemical instruments and methods, calcium/strontium/barium compounds, etc., can solve the problems of difficult control of reaction conditions, complicated preparation process, and high cost of organic matter sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

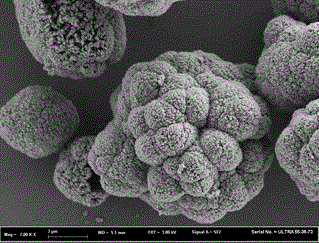

Image

Examples

Embodiment 1

[0019] 1) Under the action of mechanical stirring, dissolve ferulic acid in distilled water and add 0.1mol / LBa(OH) 2 Adjust the pH value of the solution to form a ferulic acid organic matter solution of 10g / L, pH11;

[0020] 2) Under the action of mechanical stirring, add 30mL of 1.5mol / LpH=7.2 CaCl to 30mL of ferulic acid organic matter solution obtained in step 1) 2 solution, forming ferulic acid-CaCl 2 mixed growth system;

[0021] 3) Under the condition of stirring speed of 150r / min and 50℃, ferulic acid-CaCl obtained in step 2) 2 Add 30mL of 1.5mol / L Na at pH=7.2 dropwise to the mixed growth system 2 CO 3 In the solution, after the dropwise addition, cool the above solution to 23°C at room temperature to form ferulic acid-CaCl 2 with Na 2 CO 3 mixture;

[0022] 4) At 23°C, ferulic acid-CaCl obtained in step 3) 2 with Na 2 CO 3 The mixed solution was allowed to stand for crystallization for 20 hours, and the reaction system was vacuum filtered to obtain crystals...

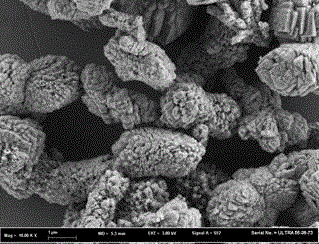

Embodiment 2

[0024] 1) Under the action of mechanical stirring, dissolve ferulic acid in distilled water and add 0.1mol / LBa(OH) 2 Adjust the pH value of the solution to form a ferulic acid organic matter solution of 20g / L, pH13;

[0025] 2) Under the action of mechanical stirring, add 30mL of 1.5mol / LpH=7.2 CaCl to 30mL of ferulic acid organic matter solution obtained in step 1) 2 solution, forming ferulic acid-CaCl 2 mixed growth system;

[0026] 3) Under the condition of stirring speed of 100r / min and 40℃, ferulic acid-CaCl obtained in step 2) 2 Add 30mL of 1.5mol / L Na at pH=7.2 dropwise to the mixed growth system 2 CO 3 In the solution, after the dropwise addition, cool the above solution to 23°C at room temperature to form ferulic acid-CaCl 2 with Na 2 CO 3 mixture;

[0027] 4) At 23°C, ferulic acid-CaCl obtained in step 3) 2 with Na 2 CO 3 The mixed solution was allowed to stand for crystallization for 20 hours, and the reaction system was vacuum filtered to obtain crystals...

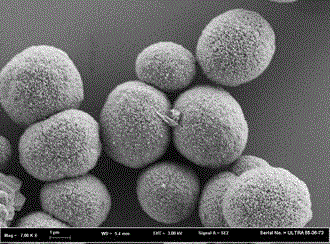

Embodiment 3

[0029] 1) Under the action of mechanical stirring, dissolve ferulic acid in distilled water and add 0.1mol / LBa(OH) 2 Regulate solution pH value, form the ferulic acid organic matter solution of 30g / L, pH7;

[0030] 2) Under the action of mechanical stirring, add 30mL of 1.5mol / LpH=7.2 CaCl to 30mL of ferulic acid organic matter solution obtained in step 1) 2 solution, forming ferulic acid-CaCl 2 mixed growth system;

[0031] 3) Under the condition of stirring speed of 250r / min and 30℃, ferulic acid-CaCl obtained in step 2) 2Add 30mL of 1.5mol / L Na at pH=7.2 dropwise to the mixed growth system 2 CO 3 In the solution, after the dropwise addition, cool the above solution to 23°C at room temperature to form ferulic acid-CaCl 2 with Na 2 CO 3 mixture;

[0032] 4) At 23°C, ferulic acid-CaCl obtained in step 3) 2 with Na 2 CO 3 The mixed solution was left to stand for crystallization for 20 hours, and the reaction system was vacuum filtered to obtain crystals, which were w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com