Toothpick automatic packing machine

An automatic packaging machine and toothpick technology, applied in packaging, multiple packages, transportation and packaging, etc., can solve the problems of threatening the health of users, low production efficiency, easy to cause pollution, etc., to ensure relative continuity, improve Productivity, Hygiene Improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

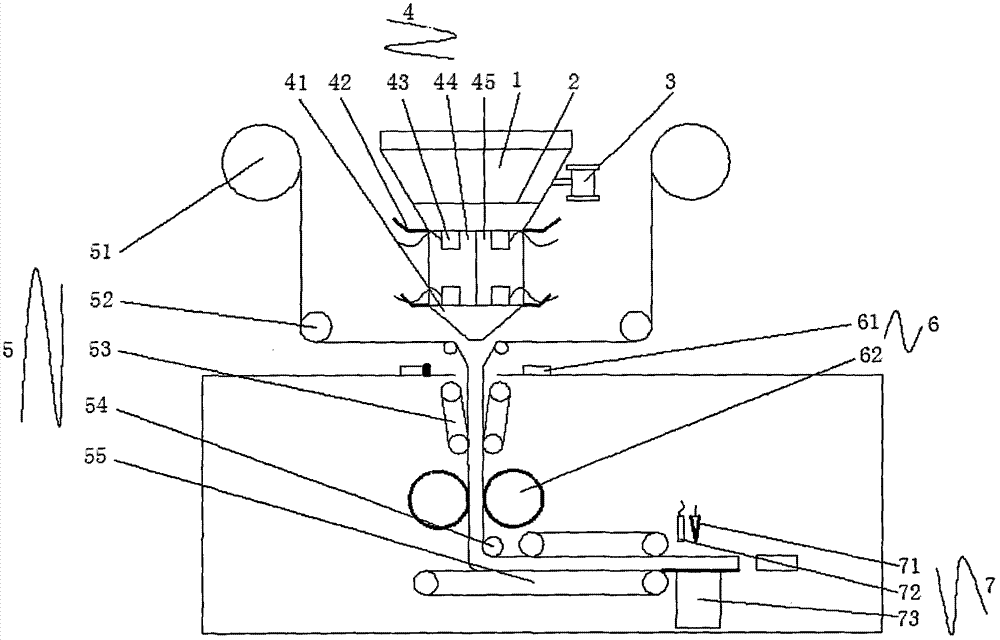

[0028] Such as figure 1 As shown, an automatic packaging machine for toothpicks includes: a frame, a trapezoidal hopper 1, an arrangement grid 2, a vibrator 3, a toothpick metering mechanism 4, a plastic film feeding mechanism 5, a film bag sealing mechanism 6, and a film bag cutting mechanism 7 , Power mechanism and automatic control mechanism.

[0029] The bottom of the trapezoidal hopper 1 is provided with a rectangular opening, and the trapezoidal hopper 1 is set on the frame; the arrangement grid 2 is horizontally arranged in the middle of the trapezoidal hopper 1, and the grid of the arrangement grid 2 is a rectangular grid along the toothpick storage direction. To correct a small amount of toothpicks disorder caused by artificial toothpicks; the vibrator 3 is arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com