Method for sewing business wear sleeve meeting bending degree of human body elbow

A technology for business wear and sleeves, which is applied in the field of garment processing, can solve the problems affecting the overall appearance and aesthetics of clothing that affect the comfort of wearing, and achieve the effect of simple operation and improved product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

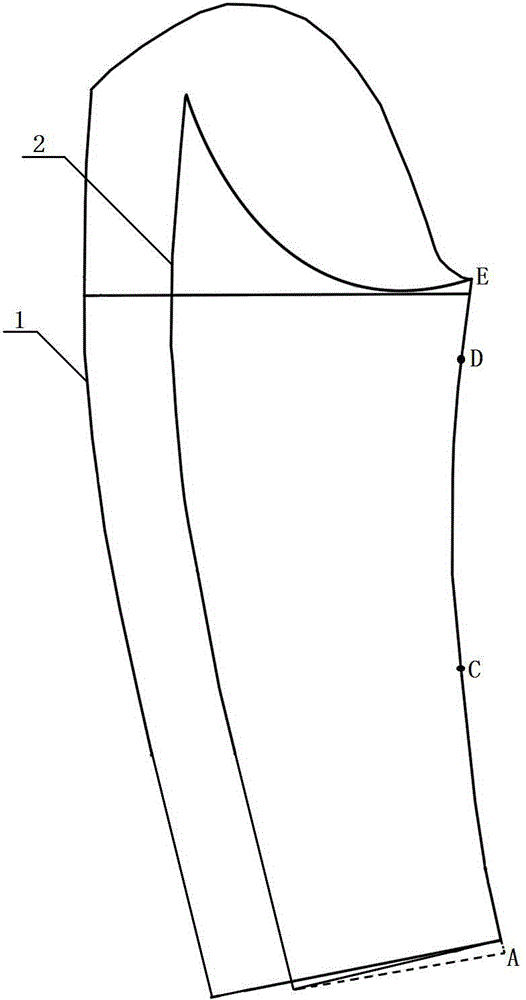

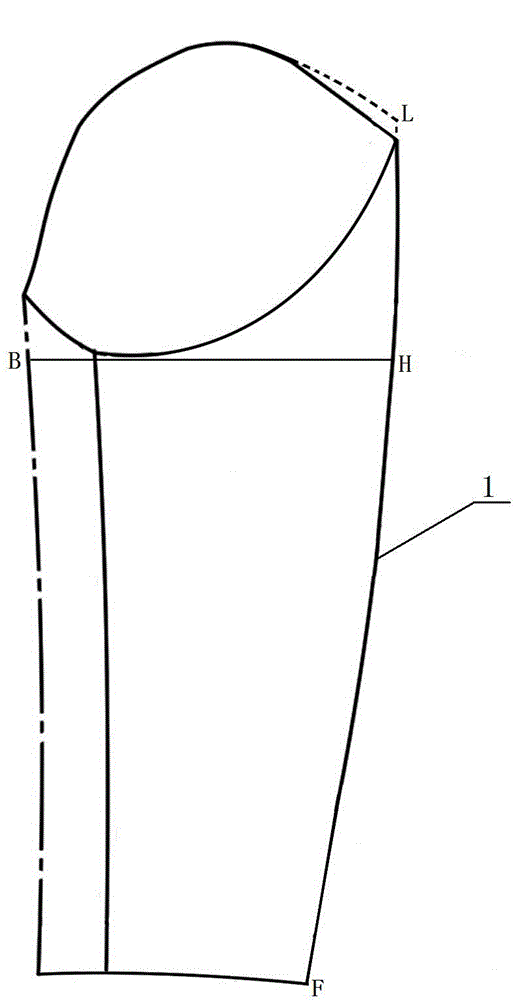

[0015] like figure 1 , 2 Shown, the present invention adopts following processing steps:

[0016] 1. Cutting: Cut the large sleeve piece 1 and the small sleeve piece 2 so that the bottom seam of the small sleeve piece 2 is 0.5-0.7cm longer than the sleeve bottom seam of the big sleeve piece 1 at the cuff, so that the large sleeve piece 1 is outside the sleeve than the small sleeve piece 2 The length of the top of the seam is 0.2-03 cm;

[0017] 2. Determine the sleeve bottom seam point: the cuff end point of the sleeve bottom seam of the small sleeve piece 2 is point A, the intersection point of the armpit end point of the small sleeve piece 2 sleeve and the sleeve bottom seam is point E, and the 13-14 cm upward along point A is the sleeve bottom seam At point C, the AC line is the first cut-off line when suturing the small sleeve piece 2; point D is the sleeve bottom seam point 5 cm down from point E, and the CD line is the second cut-off line when the small sleeve piece 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com