A five-axis linkage food 3D printer

A 3D printer and five-axis linkage technology, applied in the field of food 3D printers, can solve the problems of reducing printing efficiency, increasing printing costs, and low printing efficiency, and achieve the effect of improving printing efficiency, reducing printing costs, and easily realizing printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

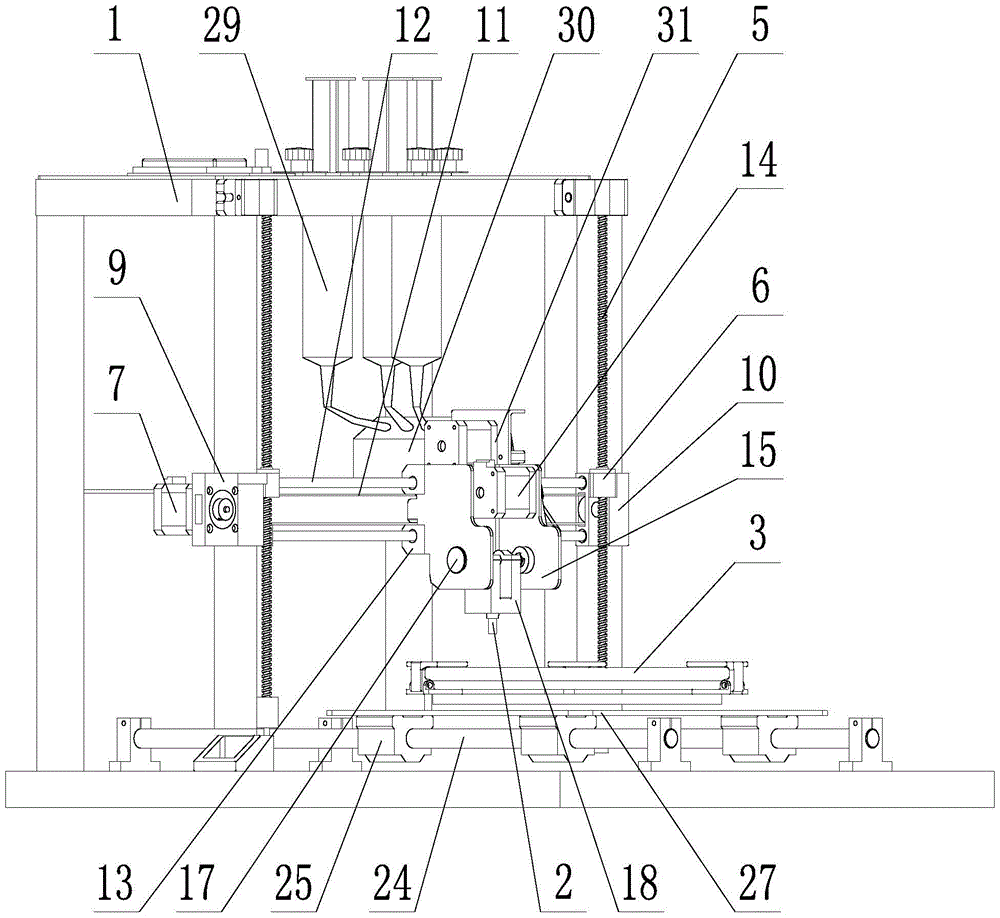

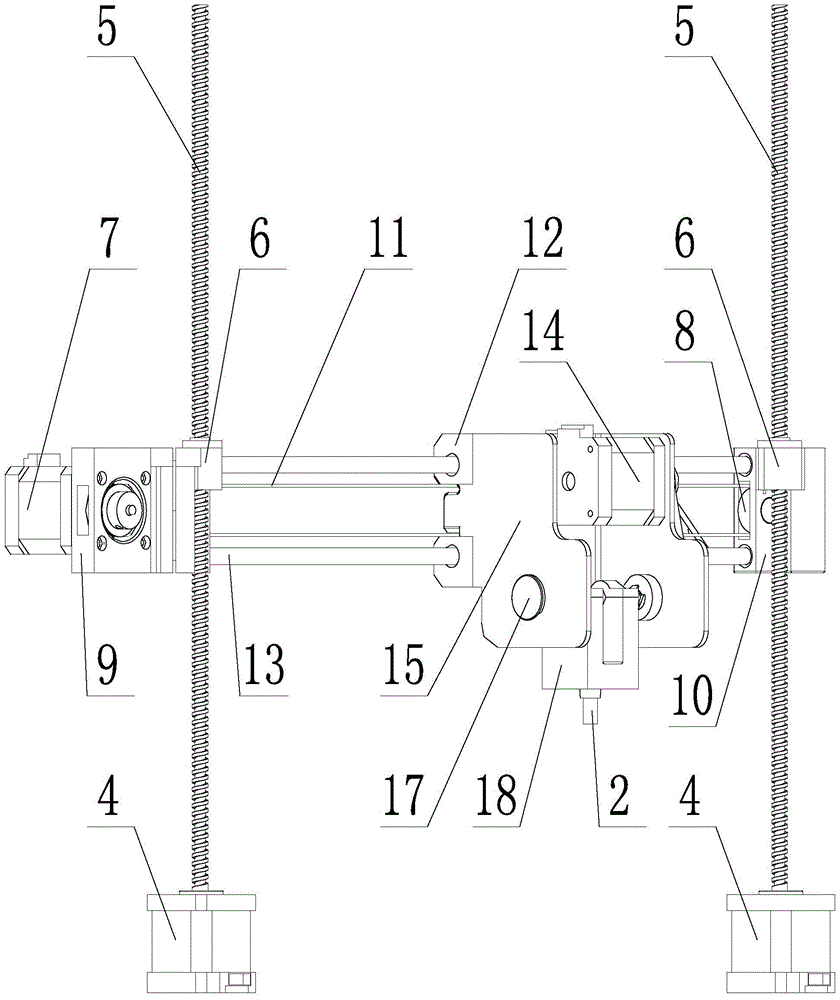

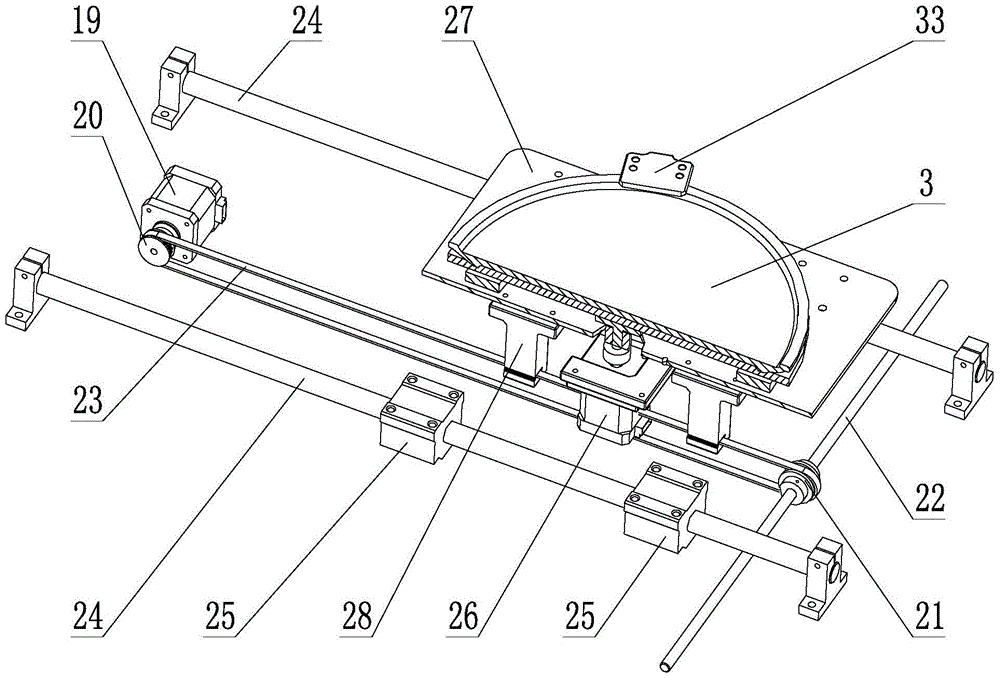

[0022] Such as figure 1 , 2 As shown in , 3 and 4, a five-axis linkage food 3D printer includes a frame 1, a print head 2, a material receiving tray 3, an X-direction drive assembly, a Y-direction drive assembly, a Z-direction drive assembly, and an A-direction print head. Pendulum drive assembly, B-direction material receiving tray rotation drive assembly and storage and delivery assembly;

[0023] The Z-direction drive assembly includes a Z-direction drive motor 4, a Z-direction screw 5 and a Z-direction nut 6, the Z-direction drive motor 4 is connected to one end of the Z-direction screw 5, and the Z-direction nut 6 is set on the Z On the screw rod 5, the Z-direction drive motor 4 and the Z-direction screw rod 5 are installed on the frame 1; there are two sets of Z-direction drive assemblies, and the Z-direction screw rods 5 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com