Can containing egg milk and peanuts, and preparation method of can

A production method and custard technology, applied in the fields of application, food preparation, food science, etc., can solve the problems of high cholesterol content in egg yolk, smell of rotten eggs, application restrictions, etc., and achieve improved absorption and digestion, nutritional value, and good color and fragrance , the effect of long storage period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

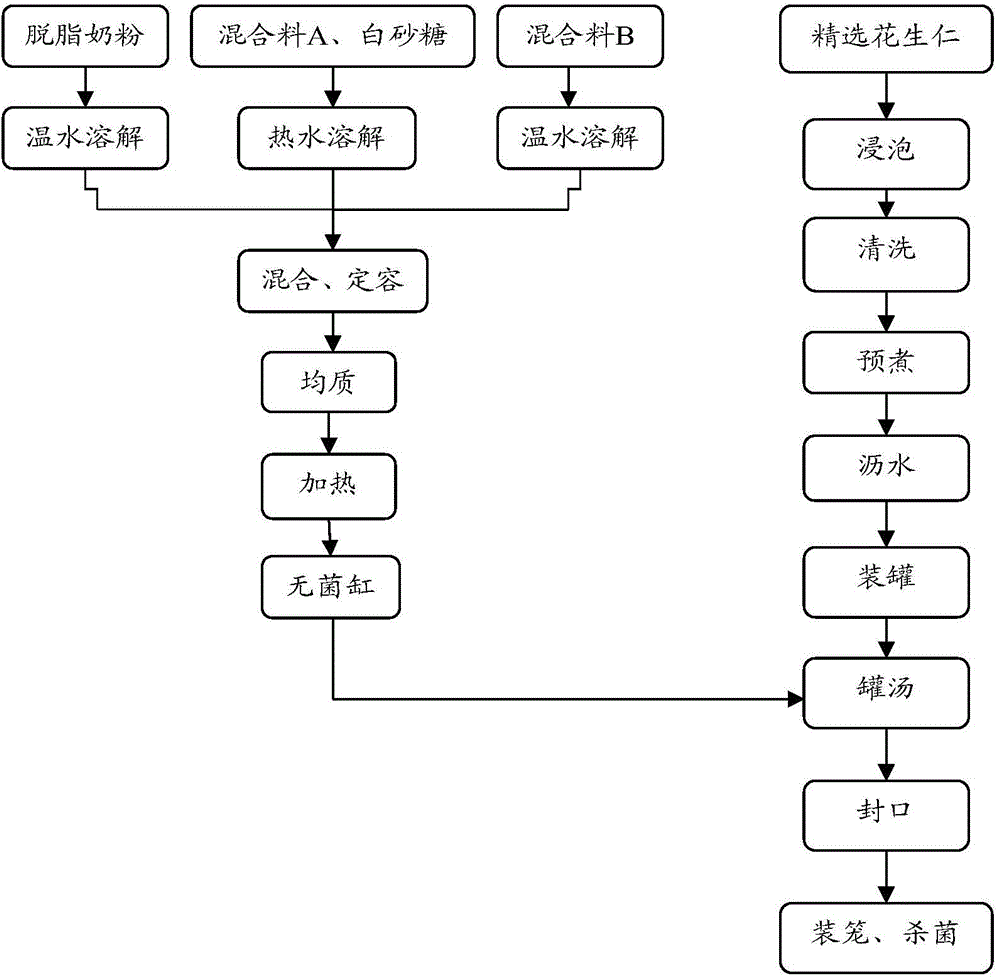

Image

Examples

Embodiment 1

[0021] A canned peanut with custard contains 100 parts by weight: 40 parts of custard solution and 60 parts of peanut kernels.

[0022] The above-mentioned custard solution is dissolved in 1000 liters of water with the following components by weight: white granulated sugar 100kg, skimmed milk powder 20kg, whole egg powder 20kg, D-sodium erythorbate 250g, xanthan gum 600g, lecithin 2kg, phosphate 400g.

[0023] The preparation of above-mentioned custard solution is accomplished through the following steps:

[0024] (1) Take skim milk powder and dissolve it in warm water, heat the warm water until the skim milk powder can be completely dissolved, and seal it for later use after dissolving; (2) Mix xanthan gum, lecithin, and phosphate to form mixture A, and mix the mixture Add A and white sugar slowly to the stirring water, heat to 95-100°C, and keep warm for 10-15 minutes for later use; (3) Take whole egg powder and D-sodium erythorbate to form mixture B, mix the mixture B is d...

Embodiment 2

[0028] A canned custard peanut, the composition of which is based on 100 parts by weight: 45 parts of custard solution and 55 parts of peanut kernels.

[0029] The above-mentioned custard solution is dissolved in 1000 liters of water with the following components by weight: white granulated sugar 125kg, skimmed milk powder 26kg, whole egg powder 35kg, D-sodium isoascorbate 350g, xanthan gum 850g, lecithin 2.5kg, phosphate 500g .

[0030] The preparation of above-mentioned custard solution is accomplished through the following steps:

[0031] (1) Take skim milk powder and dissolve it in warm water, heat the warm water until the skim milk powder can be completely dissolved, and seal it for later use after dissolving; (2) Mix xanthan gum, lecithin, and phosphate to form mixture A, and mix the mixture Add A and white sugar slowly to the stirring water, heat to 95-100°C, and keep warm for 10-15 minutes for later use; (3) Take whole egg powder and D-sodium erythorbate to form mixtu...

Embodiment 3

[0035] A canned peanut with custard contains 100 parts by weight: 50 parts of custard solution and 50 parts of peanut kernels.

[0036] The above-mentioned custard solution was dissolved in 1000 liters of water with the following components by weight: 150 kg of white granulated sugar, 30 kg of skimmed milk powder, 45 kg of whole egg powder, 500 g of sodium D-isoascorbate, 900 g of xanthan gum, 5 kg of lecithin, and 700 g of phosphate.

[0037] The preparation of above-mentioned custard solution is accomplished through the following steps:

[0038] (1) Take skim milk powder and dissolve it in warm water, heat the warm water until the skim milk powder can be completely dissolved, and seal it for later use after dissolving; (2) Mix xanthan gum, lecithin, and phosphate to form mixture A, and mix the mixture Add A and white sugar slowly to the stirring water, heat to 95-100°C, and keep warm for 10-15 minutes for later use; (3) Take whole egg powder and D-sodium erythorbate to form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com