Material cutting push device of candy molding machine

A molding machine and material technology, used in confectionery, confectionery industry, food science and other directions, can solve the problems of adding machine operators, frequent occurrence of material jams, and material waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

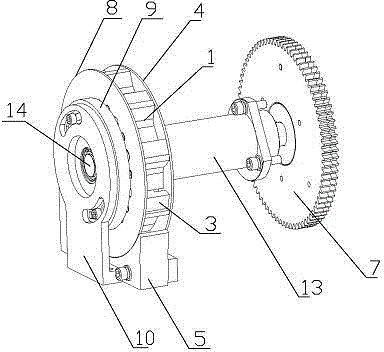

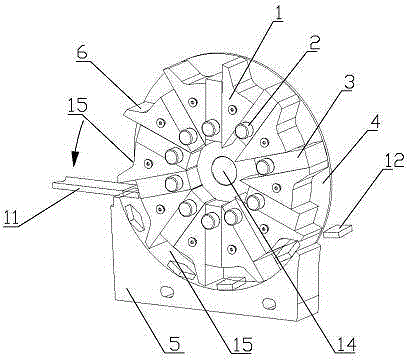

[0014] exist figure 1 and figure 2 Among them, the transmission shaft seat 13 is fixedly connected to the fuselage, and the transmission shaft 14 is rotatably connected in the transmission shaft seat 13. The transmission shaft 14 passes through the inner hole of the transmission shaft seat 13 and extends outward. At one end of the transmission shaft 14 The transmission gear 7 is fixedly installed, and the other end of the transmission shaft 14 is fixedly installed with the cutting disc 1, and the rear stop disc 4 and the front stop disc 8 are respectively installed on the two sides of the cut disc 1. The sheet 4, the front blocking disc 8 and the cutting disc 1 are arranged coaxially, and ten cutting heads 6 are evenly distributed on the disc surface of the cutting disc 1 . Between the adjacent cutting heads 6, there are chutes along the radial direction of the cutting disc 1, and the pusher slider 3 is slidably connected in the chute, and the pusher slider 3 passes throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com