Micro suction pump

A suction pump, miniature technology, applied in the direction of pumps, pumps with flexible working elements, liquid displacement machinery, etc., can solve the problems of poor reliability, low suction efficiency, poor noise suppression effect, etc., to achieve linkage Good, the effect of improving airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

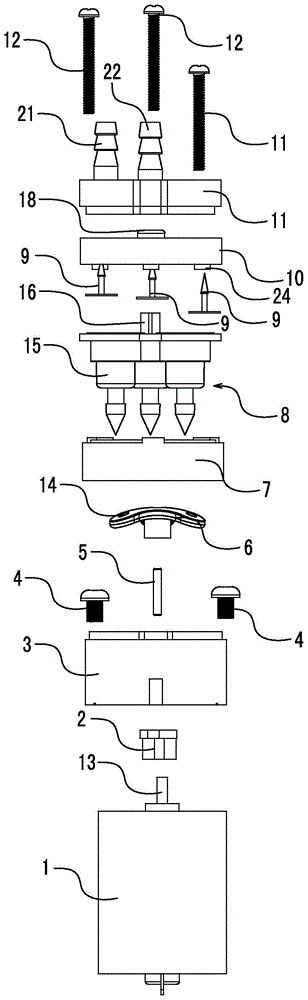

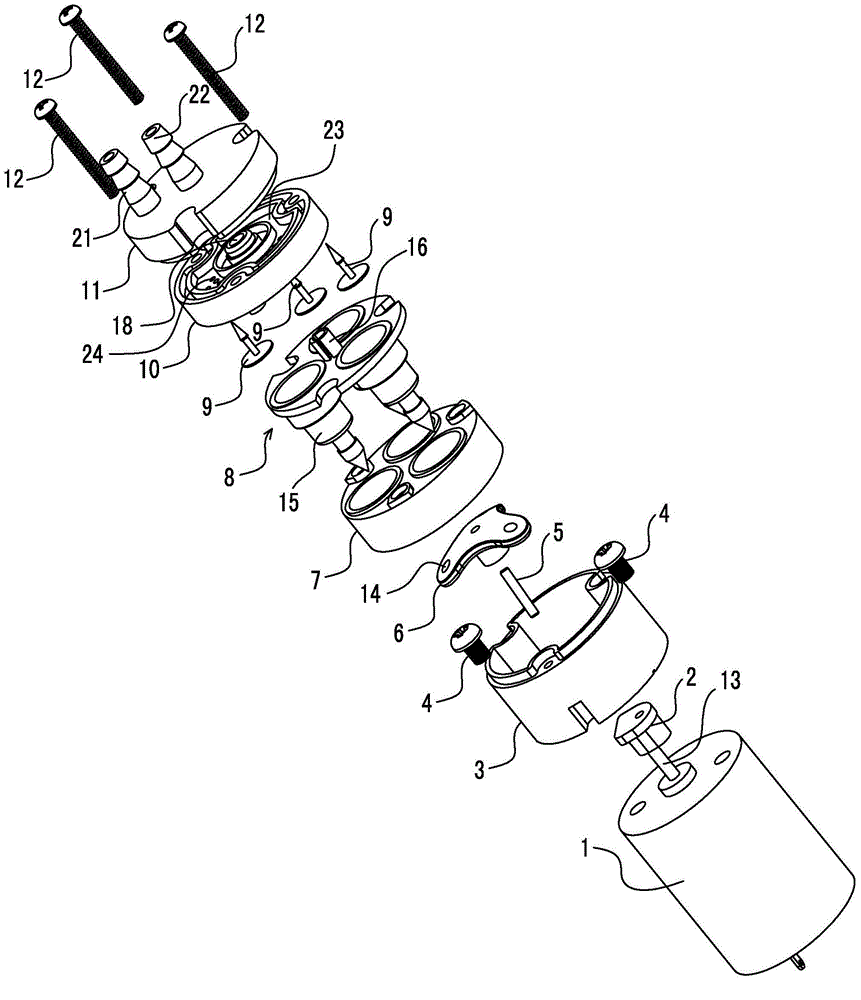

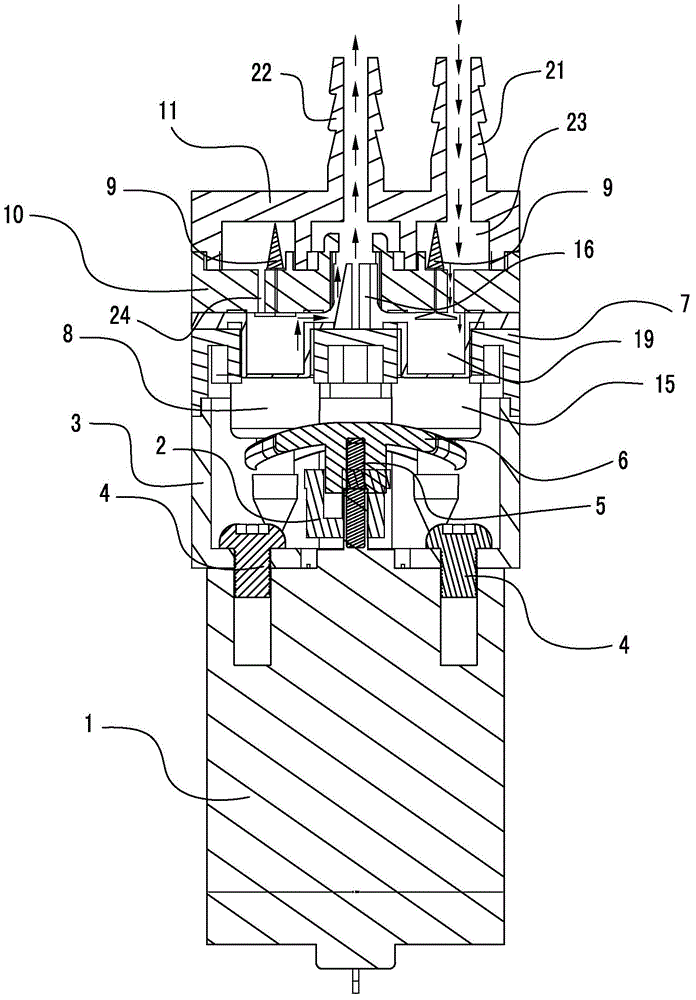

[0035] Example: see attached Figure 1~5 Shown, a kind of miniature suction pump comprises air pump assembly and motor 1; Described air pump assembly and motor 1 are arranged up and down along the vertical direction, and the rotating shaft 13 of described motor 1 is connected with described air pump assembly upwards; Said air pump The assembly includes a rocker arm frame, a flexible diaphragm group 8 and a valve assembly 10 arranged from bottom to top; wherein,

[0036]The rocker arm frame is composed of two parts, a rocker arm 5 and a disc-shaped frame body 6. The rocker arm 5 is vertically arranged at the disc-shaped center of the disc-shaped frame body 6, and the other end of the rocker arm 5 passes through an eccentric structure 2 Connected with the rotating shaft 13 of the motor 1, the eccentric structure 2 is specifically an eccentric wheel (it can also be other eccentric structures that can realize this function, which will not be described here), so as to drive the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com