Immovable string hydraulic sandblasting fracture annulus pressure control method for gas field horizontal well

A technology of annular pressure and control method, which is applied in earthwork drilling, wellbore flushing, wellbore/well components, etc., and can solve problems such as sand discharge in decompression intervals, poor wellbore stability, and low annular pressure. Achieve the effects of ensuring the transformation effect, improving the construction efficiency and ensuring the stability of the shaft wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

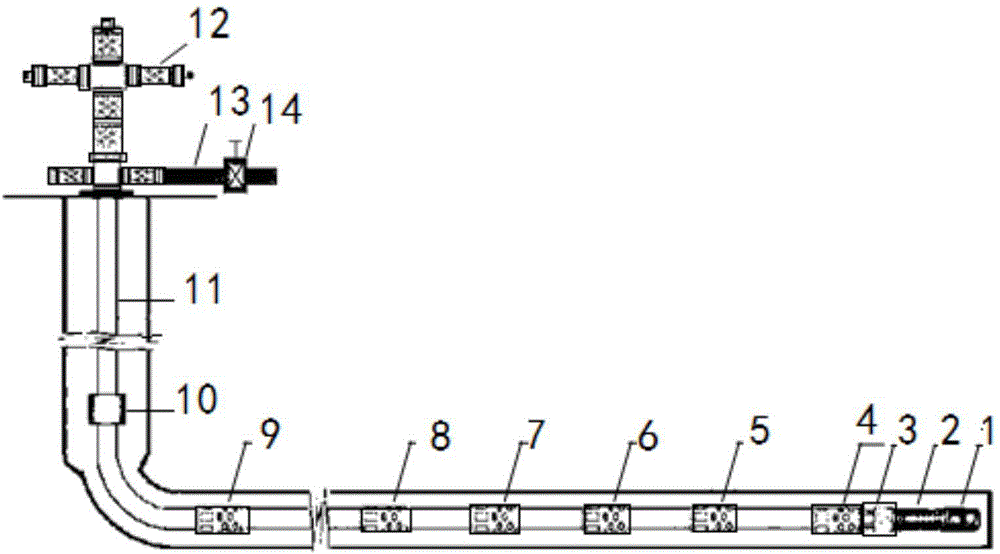

[0023] Embodiment 1: as figure 1 as shown,

[0024] Annulus pressure control device for hydraulic sandblasting fracturing of horizontal wells in gas fields, guide shoe 1 is connected to screen pipe 2, the other end of screen pipe 2 is connected to check valve 3, and the other end of check valve 3 is connected to the first stage injection 4, the other end of the first-stage injector 4 is connected to the second-stage injector 5, the other end of the second-stage injector 5 is connected to the third-stage injector 6, and the other end of the third-stage injector 6 is connected to the fourth-stage Injector 7, the other end of the fourth-stage injector 7 is connected to the fifth-stage injector 8, the other end of the fifth-stage injector 8 is connected to the N-stage injector 9, and the other end of the N-stage injector 9 is connected to the safety joint 10. The other end of the safety joint 10 is connected to the construction oil pipe 11, and the other end of the construction o...

Embodiment 2

[0027] Embodiment 2: as figure 1 as shown,

[0028] The method for controlling the annular space pressure of the hydraulic sandblasting fracturing of the horizontal well in the gas field mainly includes the following steps: running the hydraulic sandblasting fracturing process string of the horizontal well in the gas field without moving the string, and aiming the injectors at the planned reconstruction position ; Install a throttle valve at the outlet of the wellhead casing, and connect the casing pipeline to the mud pool; perform sandblasting and perforation on the target section according to the construction design. pressure; after the perforation is completed, increase the displacement and increase the jet pressure, and at the same time adjust the annular pressure through the throttle valve, press the formation and close the casing gate to carry out the main fracturing construction. During the main fracturing construction of each section, the whole process Inject liquid n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com