Steel column mounting operation platform and mounting method thereof

A technology for operating platforms and installation methods, which is applied in construction, building construction, and construction material processing, and can solve problems such as long time periods, excessive hands, time-consuming and labor-intensive, etc., so as to achieve the safety of personnel and speed up the installation progress , the effect of reducing risk factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to illustrate the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

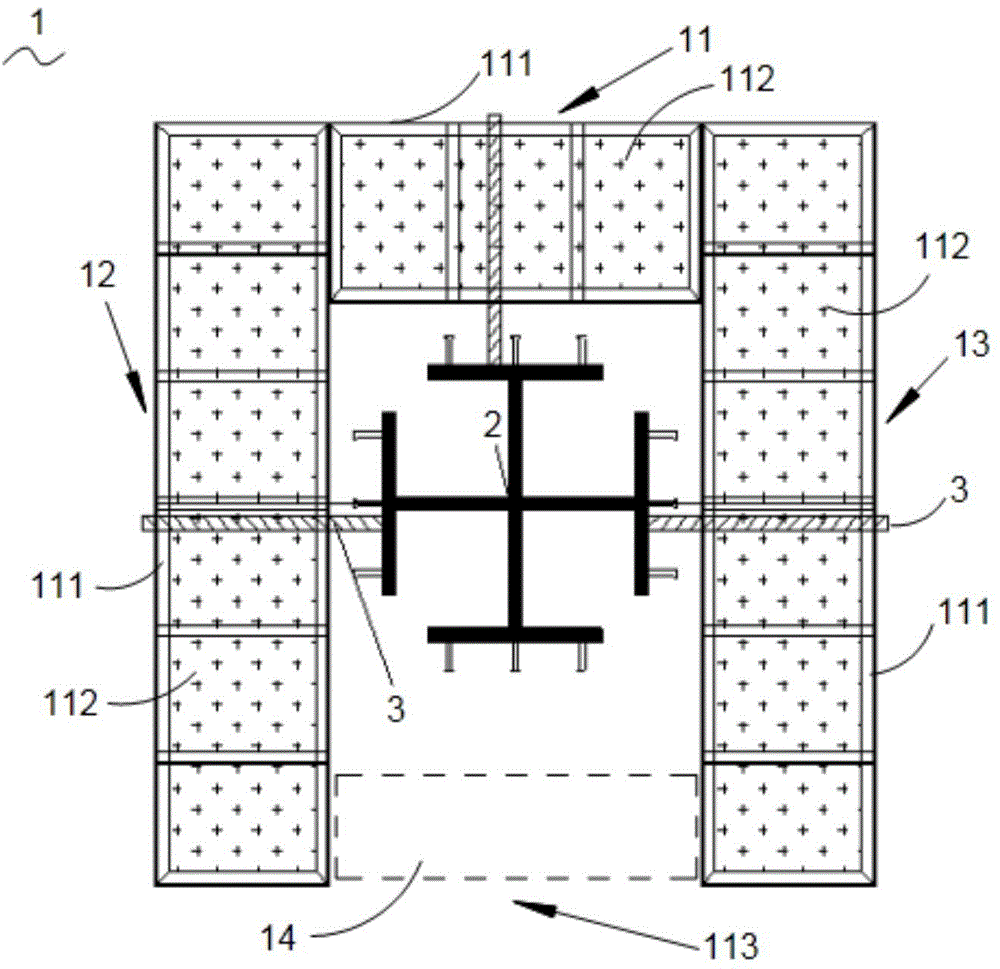

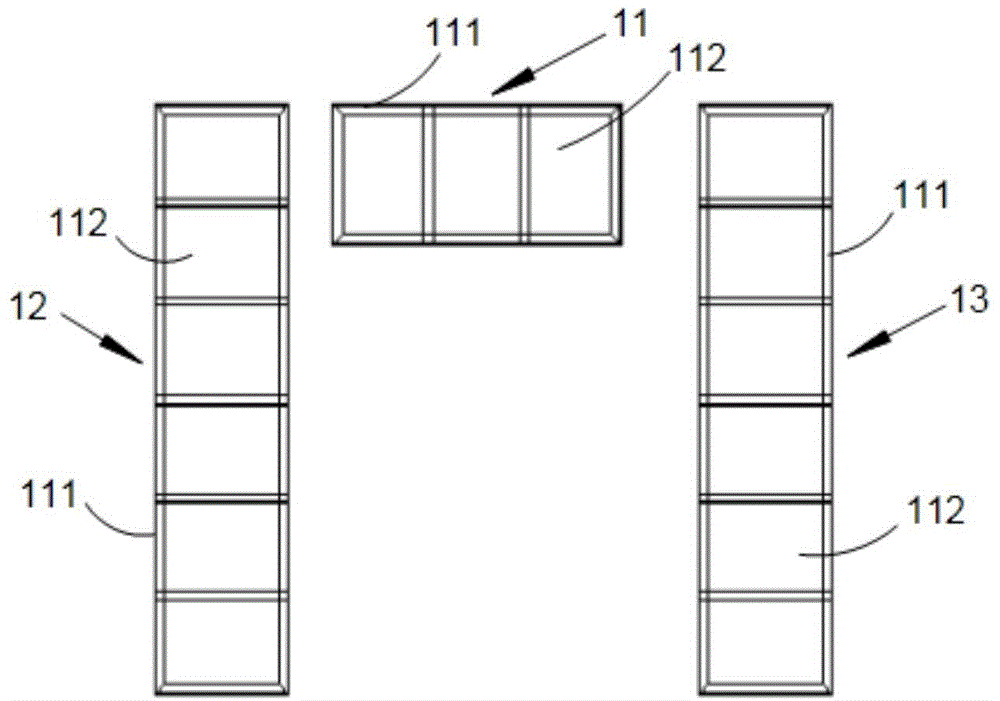

[0028] see figure 1 , figure 2 , figure 1 Shown is a top view of the steel column installation operation platform of the present invention. figure 2 Shown is a schematic exploded view of the structure of the steel column installation and operation platform of the present invention. The shown steel column installation operation platform 1 includes: a first construction operation platform 11, and the first construction operation platform 11 further includes a load-bearing frame 111 for forming a surrounding closed structure, and a frame set on the load-bearing frame 111 The bearing plate 112; the second construction operation platform 12 and the third construction operation platform 13, the second construction operation platform 12 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com