Method for installing abnormal-shaped extremely-large overhung steel truss under process monitoring construction

A technology of process monitoring and installation method, applied in the processing of building materials, construction, building structure, etc., can solve the problems of inconvenient processing and manufacturing of special-shaped steel pipe trusses, and achieve the effects of uniform force, prevention of heat concentration, and difficulty in deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

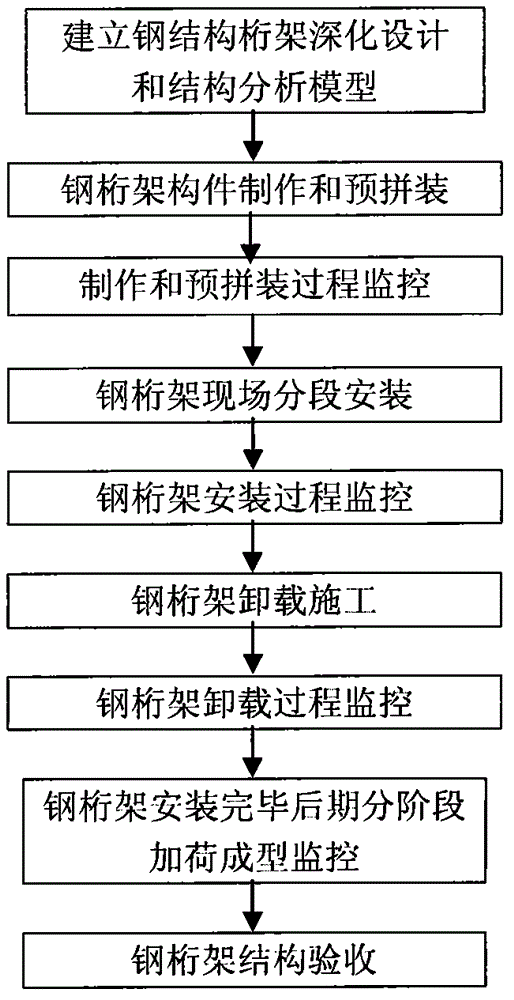

[0031] Embodiment 1: as attached figure 1 As shown, the sequence of steps in the installation method is: establishment of steel structure truss detailed design and structural analysis model, steel truss component fabrication and pre-assembly, fabrication and pre-assembly process monitoring, steel truss site segmental installation, steel truss installation process monitoring, steel truss Truss unloading construction, steel truss unloading process monitoring, steel truss installation stage loading and forming monitoring, steel truss structure acceptance.

[0032] The specific process includes:

[0033] ①Establish the detailed design and structural analysis model of the steel truss structure;

[0034] Establish the detailed design model of steel truss structure. Through the analysis and deepening of the design model, guide the factory's CNC blanking, component assembly, welding forming, pre-assembly and other processes; determine the steel truss production and installation plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com