Retractable beam used for elevator shaft formwork platform

A technology of telescopic beams and elevator shafts, applied in the field of telescopic beams, can solve the problems of simple platform safety hazards, heavy workload, labor and time-consuming, etc., and achieve the effects of improving construction efficiency, low production costs, and improving technical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

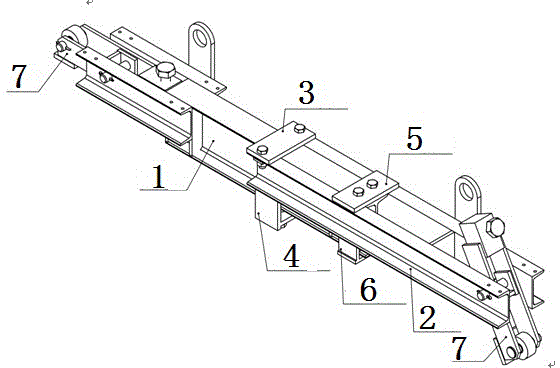

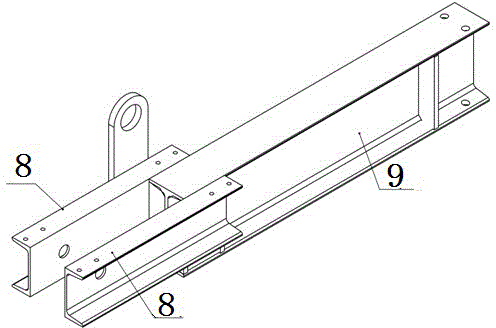

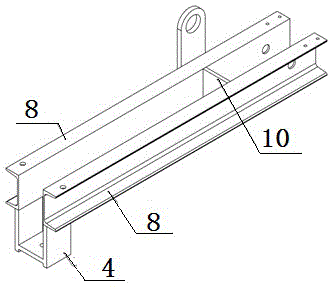

[0022] Referring to the accompanying drawings, the elevator shaft formwork platform telescopic beam of the present invention includes a telescopic beam with automatic return pawls installed at both ends, including a fixed beam, an adjustment beam and an automatic return pawl installed at one end of the adjustment beam; The beam is welded by channel steel and I-steel. The adjustment beam is made of two channel steels spaced back to back and welded with a steel plate in the middle. The I-steel at one end of the fixed beam is set between the two channel steels of the adjustment beam. The first pressing block is welded to the bottom of the adjusting beam, the upper pressing block is locked on the top of the adjusting beam with a bolt assembly, the upper pressing block is locked on the top of the I-beam of the fixed beam with a bolt assembly, and the lower pressing block is locked with a bolt assembly At the bottom of the I-beam of the fixed beam; the automatic return pawl includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com