Lightgage steel joist composite wall body and construction technology

A light steel keel and composite wall technology, which is applied in the field of keel composite walls, can solve the problems of poor concrete fluidity, unfavorable pouring concrete flow, and increased construction time, so as to achieve strong fastening, prevent bending deformation, The effect of speeding up the progress of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

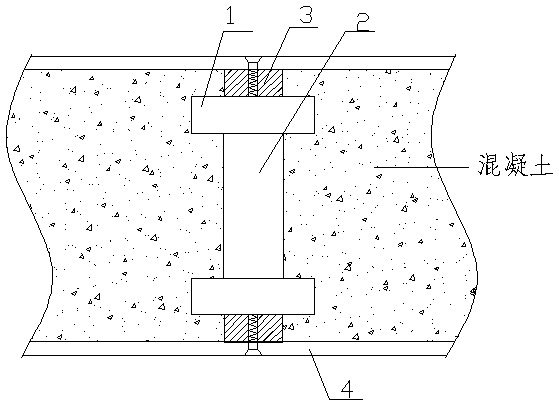

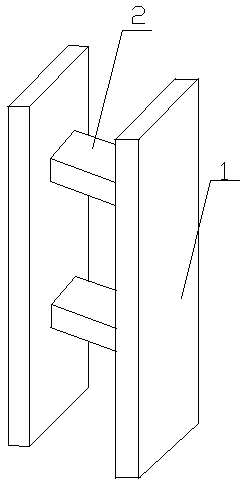

[0032] Such as figure 1 and figure 2 Shown: the present invention provides a light steel keel composite wall, including the keel and panels 4 on both sides of the wall, the keel includes a ground keel, a top keel, a column keel and a vertical keel, and the column keel is set Both ends of the composite wall are connected with the building structure wall, and several vertical keels are evenly arranged between the panels 4, and the vertical keels include two vertical steel plates 1 and several horizontal steel plates evenly arranged between the vertical steel plates 2. Bridge break pads 3 are set between the vertical keel and the panel 4 . The vertical keel is a structure combined with square tubes, which avoids the shortcomings of the original C-shaped or U-shaped keel with poor concrete circulation. The structure uses square tubes to form two vertical steel keels, and square tube steel plates are used between the steel keels As a fastening connection, the gap between the squ...

Embodiment 2

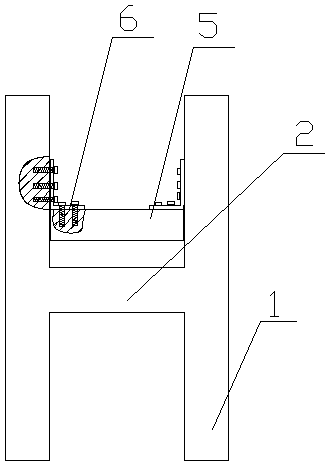

[0035] Such as image 3Shown: the present invention also provides a light steel keel composite wall, including the keel and panels 4 on both sides of the wall, the keel includes a ground keel, a top keel, a column keel and a vertical keel, and the column keel It is arranged at both ends of the composite wall and connected with the building structure wall. Several vertical keels are evenly arranged between the panels 4, and the vertical keels include two vertical steel plates 1 and several horizontal keels evenly arranged between the vertical steel plates. A steel plate 2, a broken bridge cushion block 3 is arranged between the vertical keel and the panel 4, and a cross-bracing keel 5 is arranged between the vertical keels, and the cross-bracing keel 5 and the vertical keel are connected through corner brackets 6 . When the composite wall is high, cross-bracing keels are arranged between the vertical keels to ensure the firmness of the vertical keels and prevent the keels from ...

Embodiment 3

[0037] The present invention also provides a construction method of a light steel keel composite wall, comprising the following steps:

[0038] 1) According to the architectural design drawing, pop up the center line and side line of the partition wall on the floor of the interior floor, and lead to the two main structural walls or columns and the bottom surface of the floor. Measure to the two main structural walls or columns and the bottom of the floor, and pop up the opening line of the door and window at the same time to determine the installation position and structure of the composite wall, the size of the project, and make preparations before the installation of the composite wall to prevent the wall from being skewed. ;

[0039] 2) Install the ground keel, fix it with nails or drill holes first and connect and fix it with expansion bolts;

[0040] 3) Install the top transverse keel, fix it with nails or drill holes first and connect and fix it with expansion bolts;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com