Prefabricated foundation of combination box transformer substation with reactive compensation function

A technology of prefabricated assembly and combined boxes, which is applied in the direction of infrastructure engineering, construction, etc., to achieve the effect of shortening the construction period of the project and reducing maintenance investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

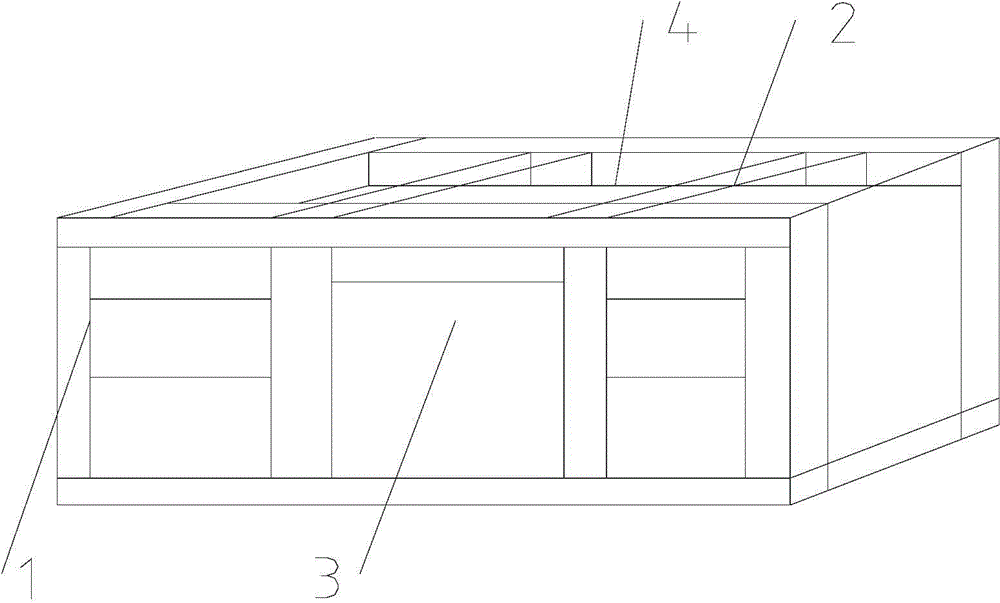

[0012] Example 1 The prefabricated basic composition of a combined box-type substation with reactive power compensation function and the role of each component:

[0013] A prefabricated assembly foundation of a combined box-type substation with reactive power compensation function, including prefabricated pillars (1), prefabricated ring beams (2), prefabricated baffles (3), and prefabricated support beams (4). The prefabricated support beam (1) is hinged to the prefabricated ring beam (2), the prefabricated support beam (4) is hinged to the prefabricated support beam (1), and the prefabricated baffle (3) ) It is connected with the prefabricated pillar (1) with a notch. The lower part of the prefabricated baffle (3) is provided with a high-voltage cable hole. The upper part of the side of the prefabricated pillar (1) is provided with ventilation holes, and the lower part is provided with a low-voltage cable hole. The prefabricated support beam (4) is provided with a lead groove...

Embodiment 2

[0014] Embodiment 2 The specific structure and connection method between the prefabricated pillar (1) and the prefabricated ring beam (2) of the prefabricated assembly foundation of a combined box-type substation with reactive power compensation function:

[0015] The prefabricated pillar (1) adopts a hollow box-shaped section form, with notches on three sides of the section, divided into three sections, each section is connected by a core column, and the upper section is left with inserts to facilitate the connection with the prefabricated ring beam (2) connection. The prefabricated ring beam (2) adopts a square cross-section and a hollow round tube is embedded inside. The column end inserts of the precast pillar (1) extend into the hole at the end of the precast ring beam (2), and then the cement mortar is used to fill it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com