Method and device for quick blockage of piping in deep foundation pit

A plugging device and a technology for deep foundation pits, which are used in infrastructure engineering, construction, etc., can solve the problems of low grouting success rate, increase construction costs, damage impermeable layers, etc., and achieve high plugging success rate and safety. and high stability, less time-consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

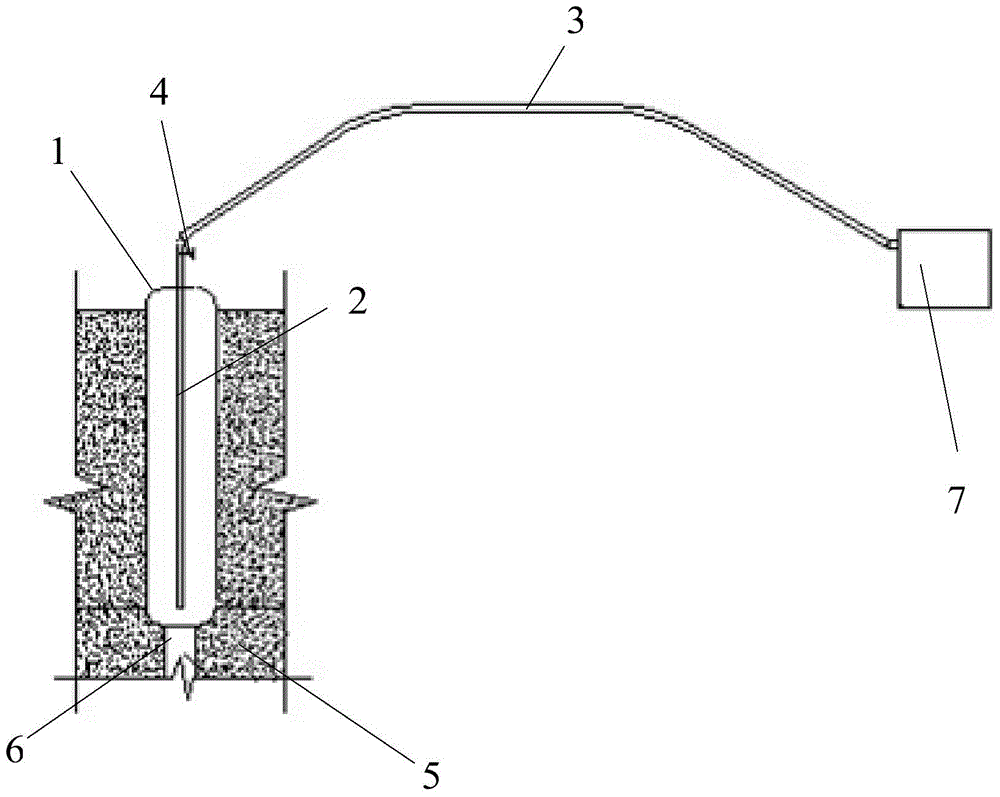

[0023] The present invention provides a method for quick plugging of piping in deep foundation pits, which is mainly used for piping plugging in deep foundation pits in open seas. The height of the bottom surface makes the geotechnical bag 1, and the diameter of the geotechnical bag 1 should be slightly larger than the aperture size of the piping hole 6, so that the piping path can be completely blocked after the geotechnical bag expands; step 2, in the geotechnical bag 1 Insert the grouting pipe 2, the length of the grouting pipe 2 is the same as the height of the geotechnical bag 1, the grouting pipe 2 stretches into the bottom of the geotechnical bag 1, and the geotechnical bag 1 is followed by the grouting pipe 2 Insert the foundation impermeable layer 5 along the piping path, and use the grouting pump 7 to inject the cement slurry into the geotechnical mold bag 1 through the grouting pipe 2; step 3, in the process of injecting cement slurry, the geotechnical mold bag 1 beg...

Embodiment 2

[0027] Compared with Embodiment 1, in step 3 of this embodiment, after stopping the injection of cement slurry into the geotechnical bag 1, the quick-setting agent is injected into the geotechnical bag 1 through the grouting pipe 2, so as to speed up the process in the geotechnical bag 1. The setting speed of cement slurry. Preferably, the quick-setting agent is water glass (sodium silicate). By injecting water glass into the geomembrane bag 1, the solidification of the cement slurry can be accelerated and the construction period can be shortened.

[0028] In the above-mentioned embodiment, the water glass enters the geotechnical bag 1 through the grouting pipe 2. After the water glass enters the geotechnical bag 1, the cement slurry in the geotechnical bag 1 solidifies rapidly, so the grouting pipe 2 There is no way to take it out. At this time, the connecting pipe and the grouting pipe 2 are disconnected, and the grouting pipe 2 is always put into the geotechnical bag 1; Ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com