Complete device for coal liquefaction

A complete set of equipment, coal liquefaction technology, applied in the preparation of liquid hydrocarbon mixture, petroleum industry, etc., can solve the problems of low red mud catalyst activity, large equipment investment, low system pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

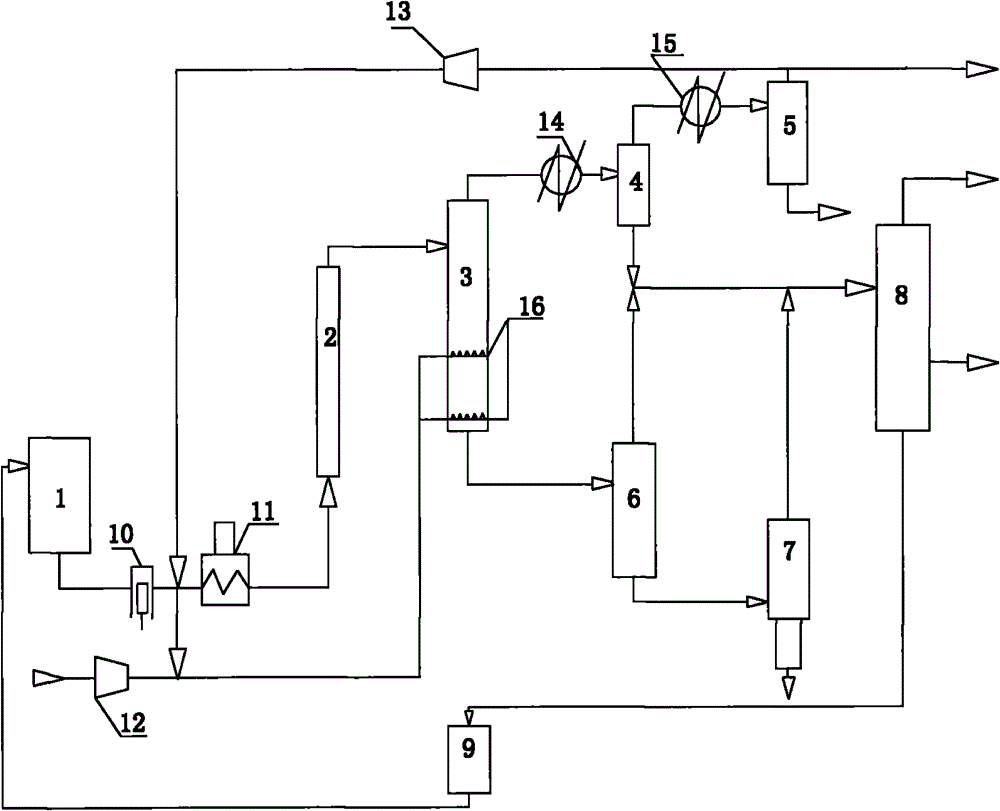

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] Depend on figure 1 It can be seen that the present invention includes a slurry tank 1, a first reactor 2, a second reactor 3 connected in series with the first reactor 2 and a fractionation tower 8, and the two reactors connected in series are all bubbling bed reactors The second reactor 3 top is provided with a separation space, and its bottom is provided with a gas distributor 16 for deep hydrogenation. The gas distributor 16 is connected with the hydrogen compressor 12 through a pipeline, and the gas distributor 16 can be installed in the second reactor. 3 The lower part is set with 1-5 pieces. The slurry tank 1 is connected to the bottom of the first reactor 2 through the high-pressure coal slurry pump 10 and the coal slurry preheating furnace 11, the output end of the first reactor 2 is connected to the input port on the upper side of the second reactor 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com