Synthesis method of s-triazine clean-series weedicide

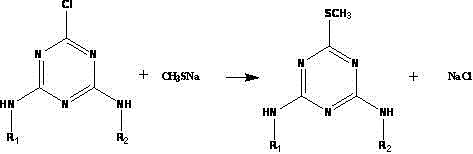

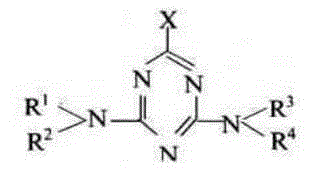

A technology of s-triazine and synthesis method, which is applied in the synthesis of s-triazine net series herbicides and the synthesis field of s-triazine herbicides, which can solve the problem of difficult control of sodium methyl mercaptan odor, waste water Deal with difficult problems, achieve considerable economic and social benefits, good product quality, and reduce power and raw material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In a 1L reaction kettle, put 350mL of isopropanol, 245.88g of 20wt% sodium methyl mercaptide liquid and 160.00g of 97wt% atrazine respectively. After sealing, stir and mix and heat up to 115°C for 50min. The pressure was 0.34 MPa, and the temperature was lowered to 60° C. after the reaction. Stand still, divide the water, and the water layer is almost odorless after the solvent is recovered by distillation. The oil layer was transferred to a 500mL four-neck flask to distill and recover the solvent, and the residue was poured into a tray, cooled, crystallized and pulverized to obtain 163.02g of white powder. The content of arazine was 97.62% as determined by HPLC, and the yield based on atrazine was 97.31%.

Embodiment 2

[0034] In a 1L reaction kettle, put 350mL of isopropanol, 247.14g of 20wt% sodium methyl mercaptide liquid and 160.00g of 97% atrazine respectively. After sealing, stir and mix and heat up to 120°C for 45min. The pressure was 0.37MPa, and the temperature was lowered to 62°C after the reaction. Stand still, separate the water, and the water layer has no peculiar smell after the solvent is recovered by distillation. The oil layer was transferred to a 500mL four-neck flask to distill and recover the solvent, and the residue was poured into a tray, cooled, crystallized and pulverized to obtain 164.81g of white powder. The content of arazine was 96.88% as detected by HPLC, and the yield based on atrazine was 97.63%.

Embodiment 3

[0036] In a 1L reaction kettle, put 350mL of isopropanol, 249.66g of 20wt% sodium methyl mercaptide liquid and 160.00g of 97% atrazine respectively. After sealing, stir and mix and heat up to 118°C for 50min. The pressure is 0.35 MPa, and the temperature is lowered to 60° C. after the reaction. Stand still, divide the water, and the water layer is almost odorless after the solvent is recovered by distillation. The oil layer was transferred to a 500mL four-neck flask to distill and recover the solvent, and the residue was poured into a tray, cooled, crystallized and pulverized to obtain 165.48g of white powder. The content of arazine detected by HPLC was 96.97%, and the yield based on atrazine was 98.12%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com