Hydraulic power clamp

A hydraulic power and fixture technology, applied in the direction of clamping, clamping devices, manufacturing tools, etc., can solve the problems of high error of plate parts, low work efficiency, increased economic expenditure, etc., to improve processing efficiency and accuracy, High clamping and dismantling effect, and the effect of reducing economic expenditure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

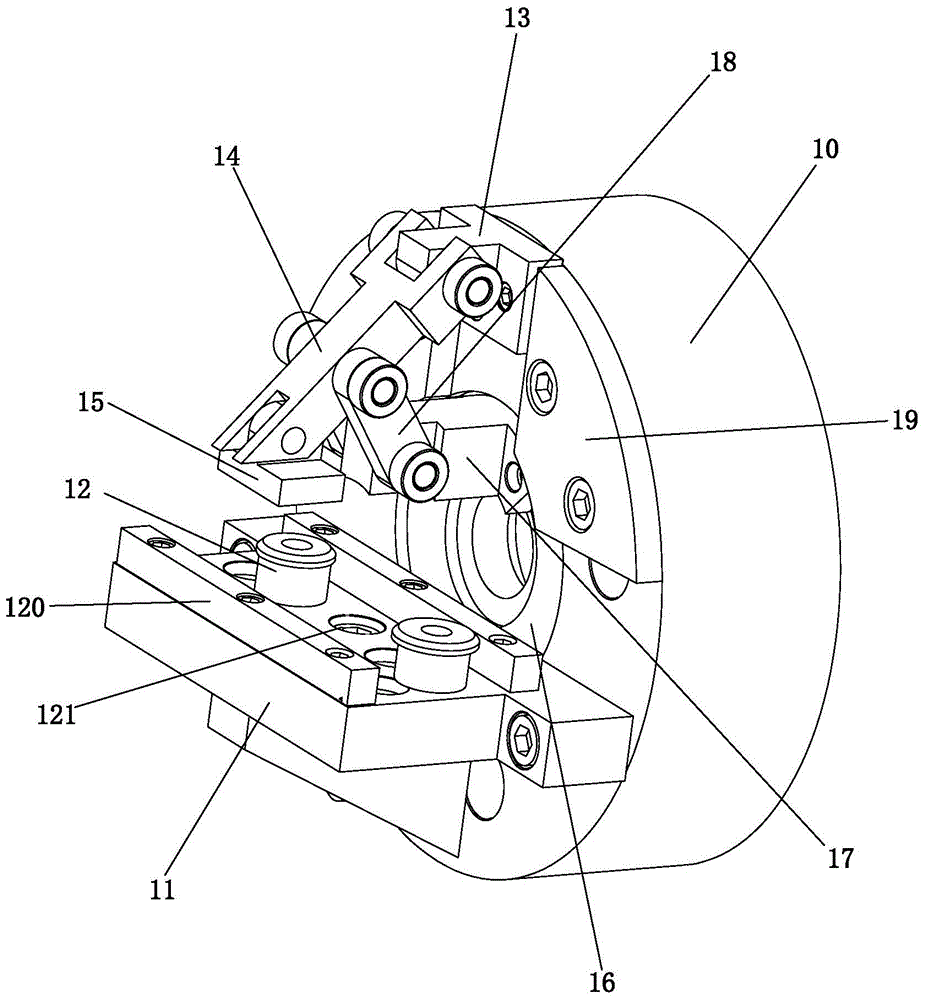

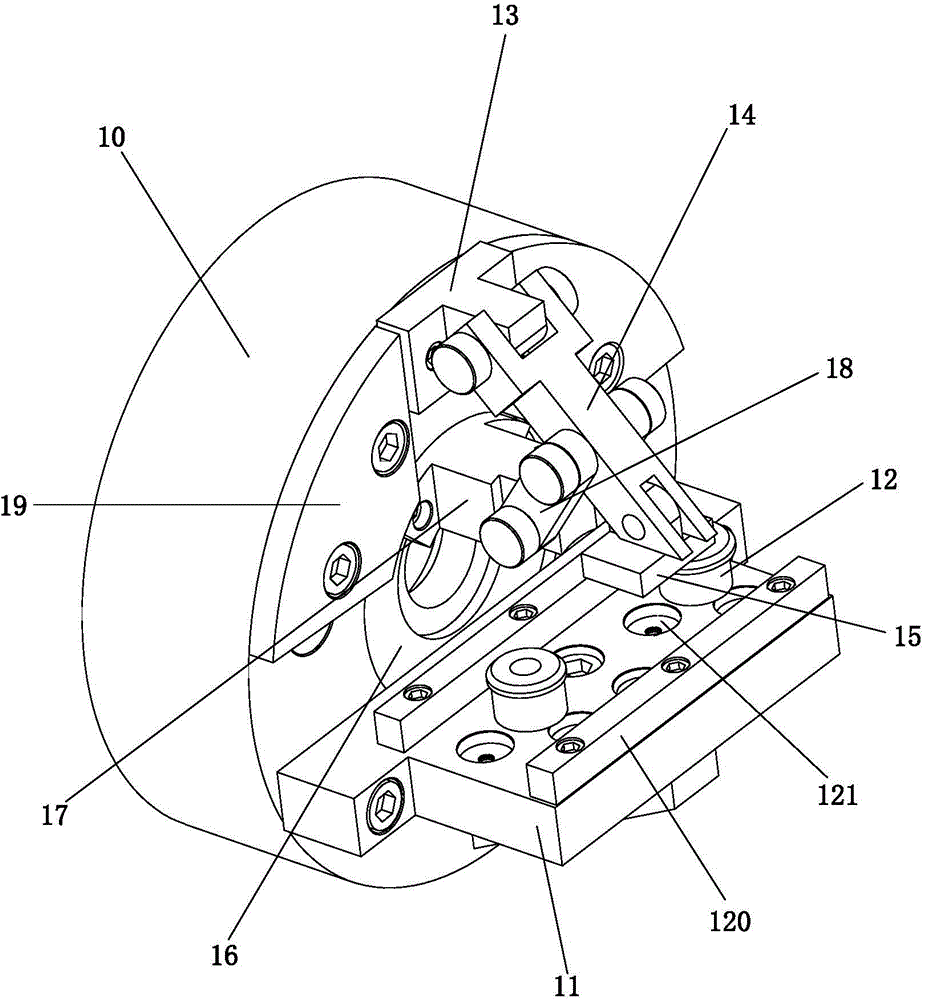

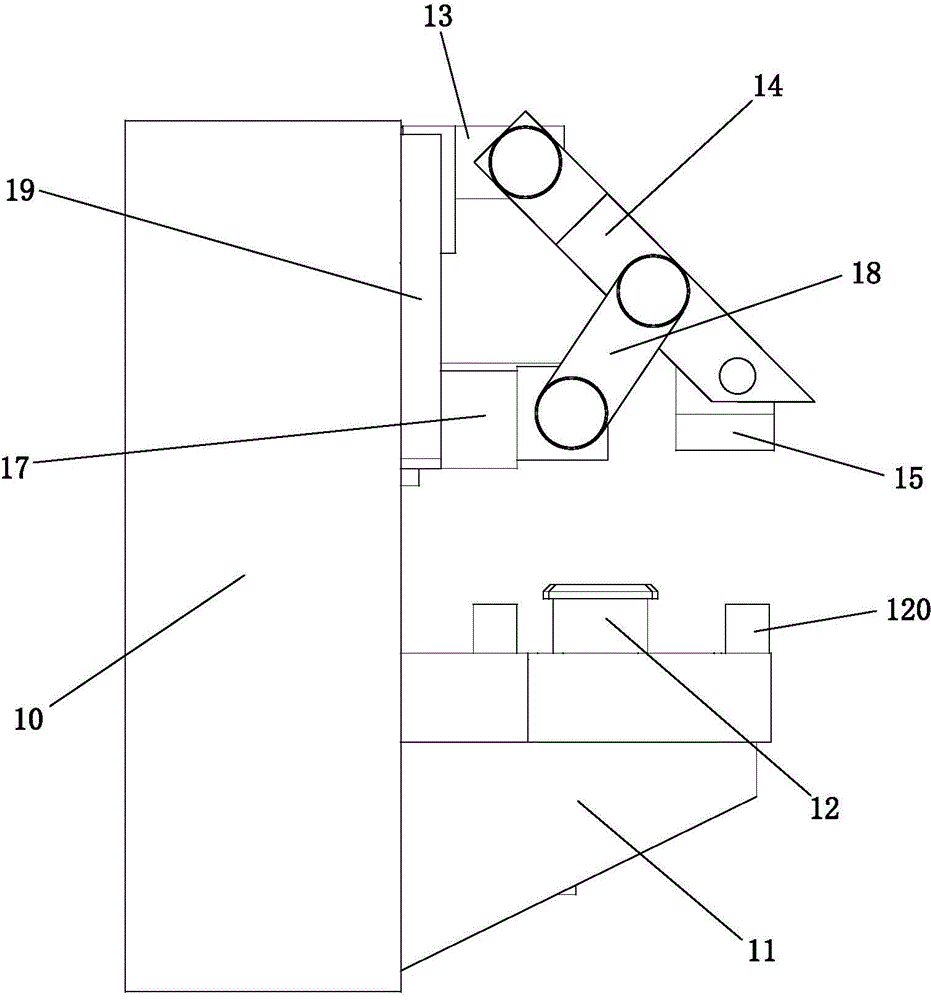

[0016] Such as Figure 1 to Figure 4 As shown, it is a hydraulic power clamp disclosed by the present invention, one side of the mounting base 10 is provided with a bent plate 11, and the side of the curved plate 11 perpendicular to the mounting base 10 is provided with replaceable two parallel clamps at intervals. The support block 120, the support block 120 is fixed on the bent plate 11 by means of screw fixing, of course, it can also be fixed by welding, or a positioning groove or a positioning hole is set at the position where the support block 120 is installed on the bent plate, The opposite surface of the support block 120 is provided with a positioning hole or a positioning groove matched with the positioning groove or the positioning hole for fixing, but for stability, the preferred screw fixing method, the replaceable setting of the support block 120 is mainly for convenience and adaptability. Different support blocks are selected for different workpieces to be proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com