Solar energy-saving greenhouse plant and manufacturing method

A technology of sunlight and workshops, applied in greenhouse cultivation, energy-saving measures, botanical equipment and methods, etc., can solve problems such as environmental pollution and large economic expenditures, and achieve the effects of ensuring heat preservation effects, saving cooling costs, saving energy and manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

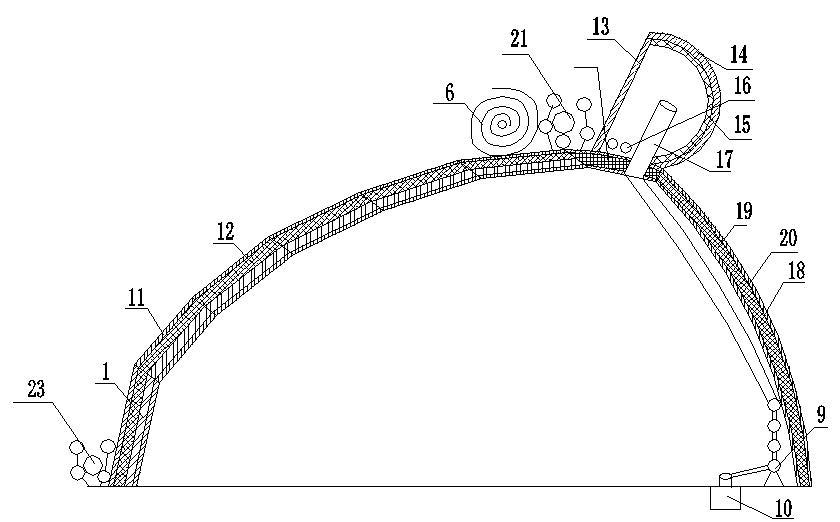

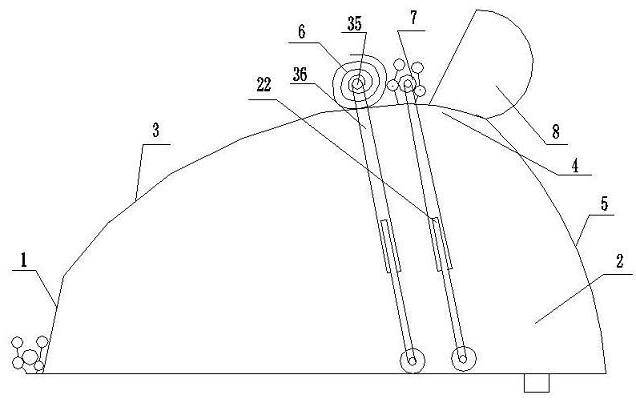

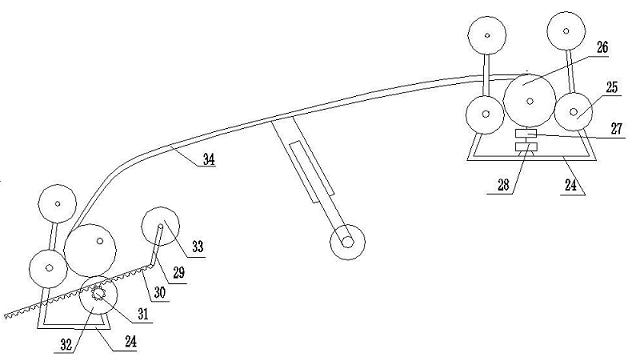

[0025] A solar energy-saving greenhouse factory building, which consists of: a foundation 1, a side insulation wall panel 2, the foundation 1 is equipped with an obliquely forward light-transmitting roof 3, and the obliquely forward light-transmitting roof 3 is connected to the insulation roof 4 , the heat preservation roof 4 is connected with the rear arch insulation wall panel 5, and the heat preservation roof 4 is equipped with heat preservation quilt 6, greenhouse automatic rainproof sunshade and snow removal device 7, and sunlight energy storage device 8 in sequence. The solar energy storage device 8 is connected to the cooling fins 9, the cooling fins 9 are connected to the underground water cellar 10, and the foundation 1 is connected to the side thermal insulation wall panels 2 on both sides of the rear arched thermal insulation wall panel 5.

Embodiment 2

[0027] In the solar energy-saving greenhouse factory building described in Embodiment 1, the oblique front roof 3 includes a group of oblique steel frames 11 , and the oblique steel frames 11 are equipped with a group of light-transmitting glass 12 .

Embodiment 3

[0029] In the solar energy-saving greenhouse factory building described in Example 1, the solar energy storage device 8 includes a transparent wall panel 13, and the transparent wall panel 13 is connected to a concave wall 14, and the concave wall 14 is connected to a concave reflective layer 15. The solar energy storage device is equipped with a hot water tank 16 and a set of solar heat storage tubes 17 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com