Cutter head structure of detachable electric shaver

A separate shaver technology, applied in metal processing and other directions, can solve problems such as damage, inconvenient cleaning, and inability to replace, and achieve the effects of easy manufacturing, economical savings, and reasonable and practical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

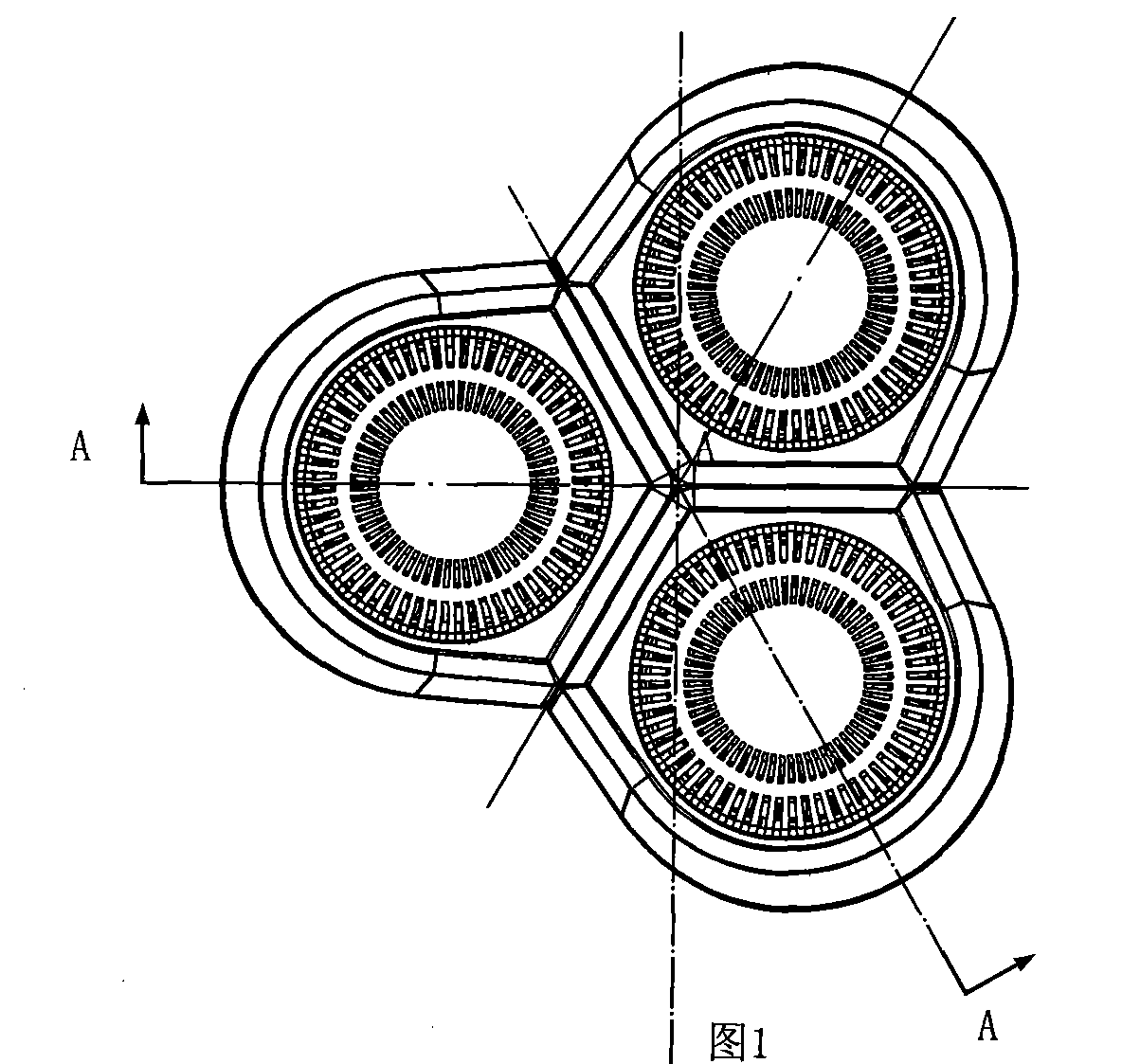

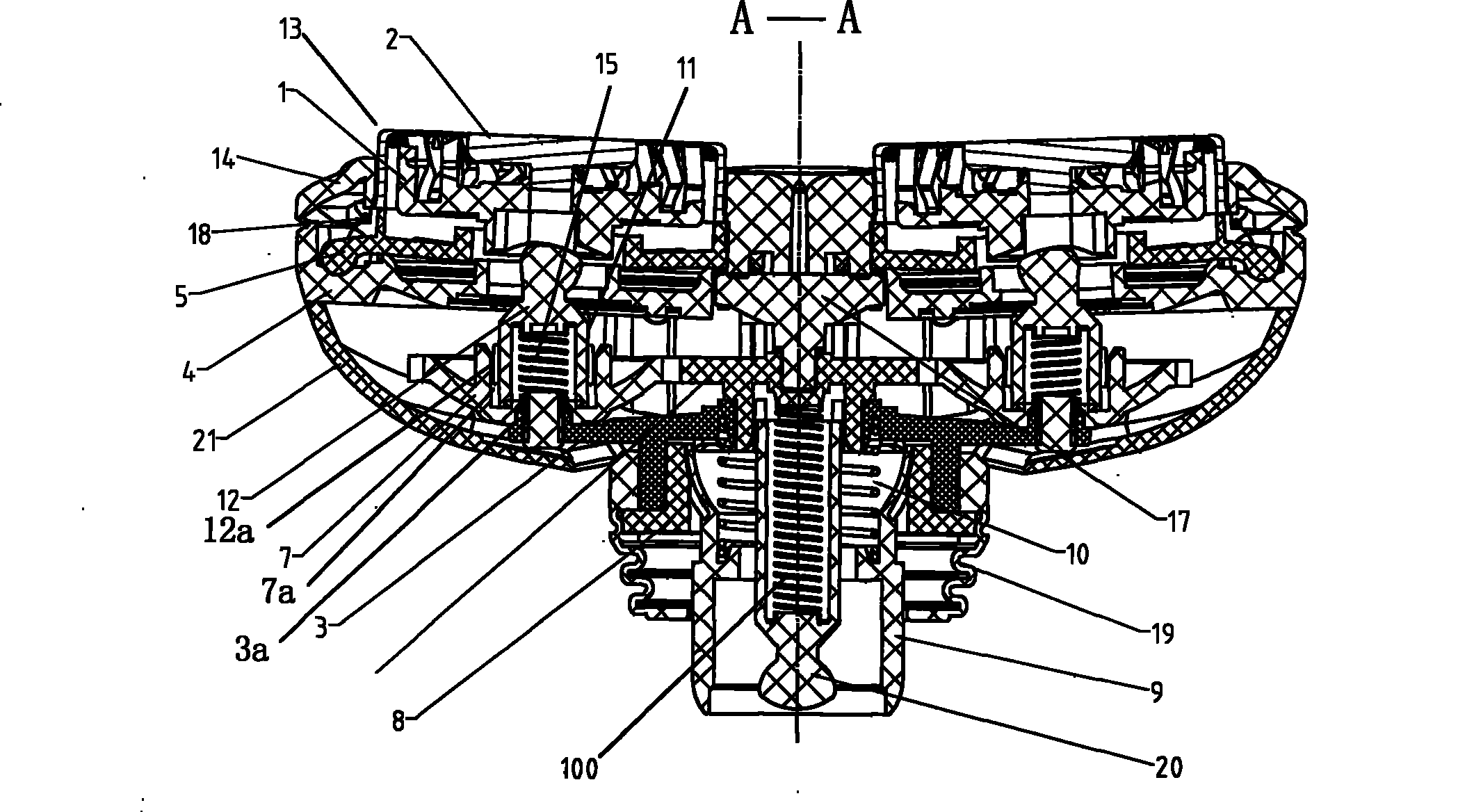

[0038] As shown in Figure 1-16, a cutter head structure of a separate electric shaver includes a plurality of rotatable blades 1, a knife net 2, a main bracket 3, a rotating bracket 4, a pressing frame 5, and a center rotating Main parts such as bull gear 6, transmission pinion 7.

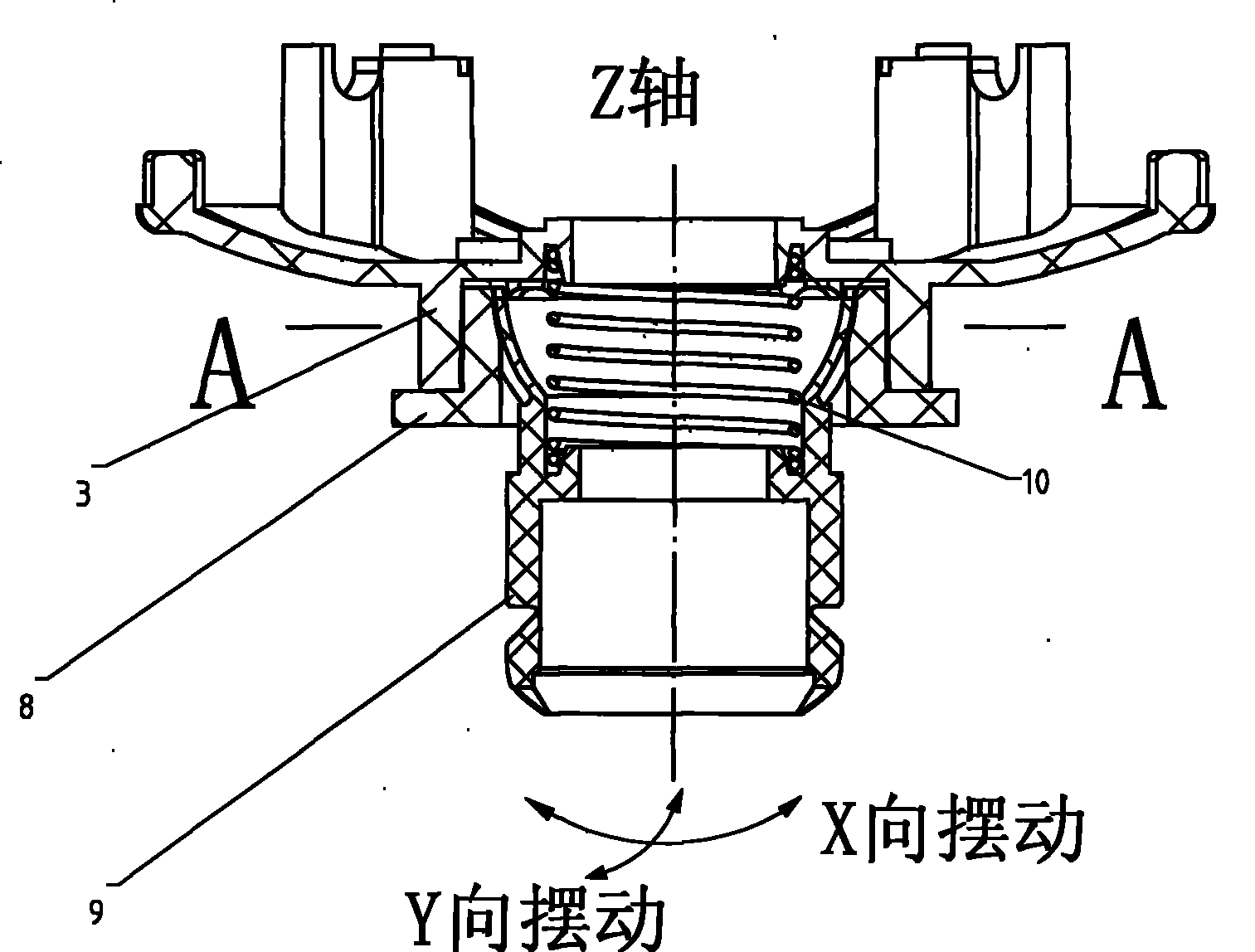

[0039] See figure 2 -5, the main bracket 3 is set on the lower cover 8 of the main bracket and connected with buttons, and a spherical installation cavity is formed inside the lower cover 8 of the main bracket, correspondingly, a partial spherical surface is formed on the outer surface of the cutter head connecting seat 9, thereby passing Spherical fit, the main bracket lower cover 8 is connected with the cutter head connecting seat 9, and the elastic element 10 is supported between the fixing groove of the main bracket 3 and the fixing groove of the cutter head c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com