Multi-beam light synthesis focus control system and control method

A focus control, multi-beam technology, applied in manufacturing tools, laser welding equipment, welding equipment, etc., can solve the problems of low single-beam energy, inability to texture, and inability to realize random distribution of micro pits, etc. The effect of optimizing the area, increasing the processing speed, and controlling the pit spacing in real time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

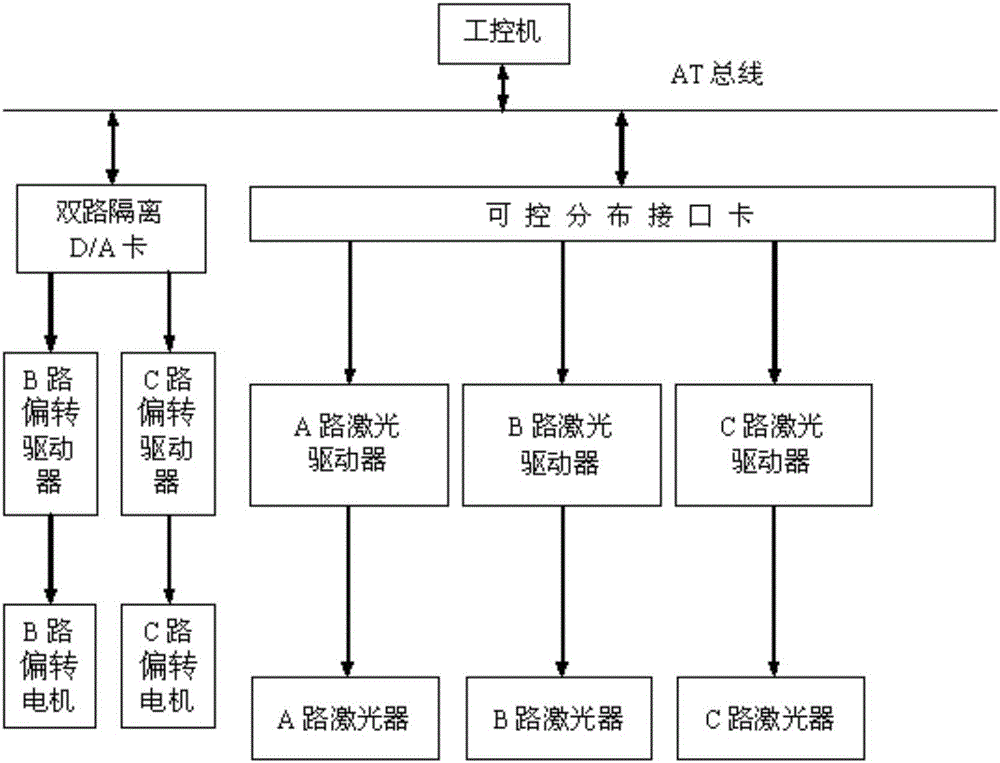

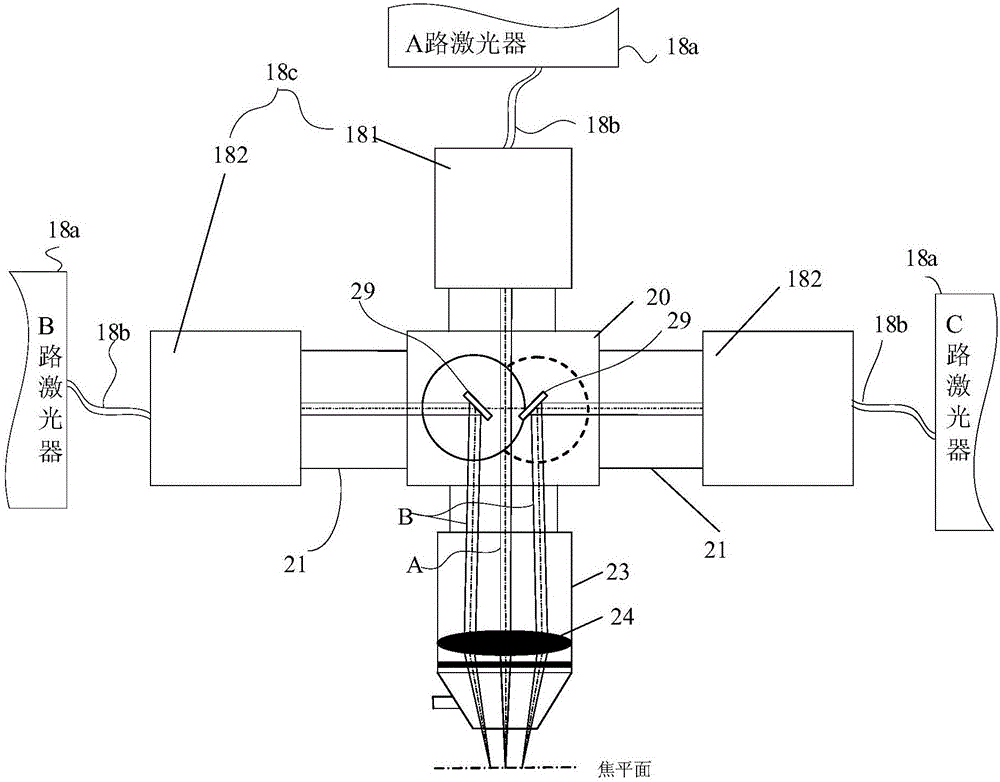

[0032] like Figure 1-6 As shown, the embodiment of the present invention provides a multi-beam light synthesis focusing control system, including:

[0033] The industrial computer is connected to the controllable distribution interface card and the two-way electrical isolation interface card respectively through the AT bus;

[0034] At least one laser control device includes at least two laser drivers; the input ends of the laser drivers are connected to the controllable distribution interface card, and the output ends of each laser driver are connected to the laser; the laser drivers are connected according to the industrial computer The laser command controls the working state and working parameters of the laser connected to it;

[0035]At least one deflection assembly control device, including at least one deflection driver, the input ends of the deflection driver are all connected to a dual-circuit electrical isolation interface card, and the output ends of the deflectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com