Novel garbage sorting machine

A garbage sorter, a new type of technology, is used in the separation of solids, the separation of solids from solids by air flow, chemical instruments and methods, etc. , The overall structure is simple and easy to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

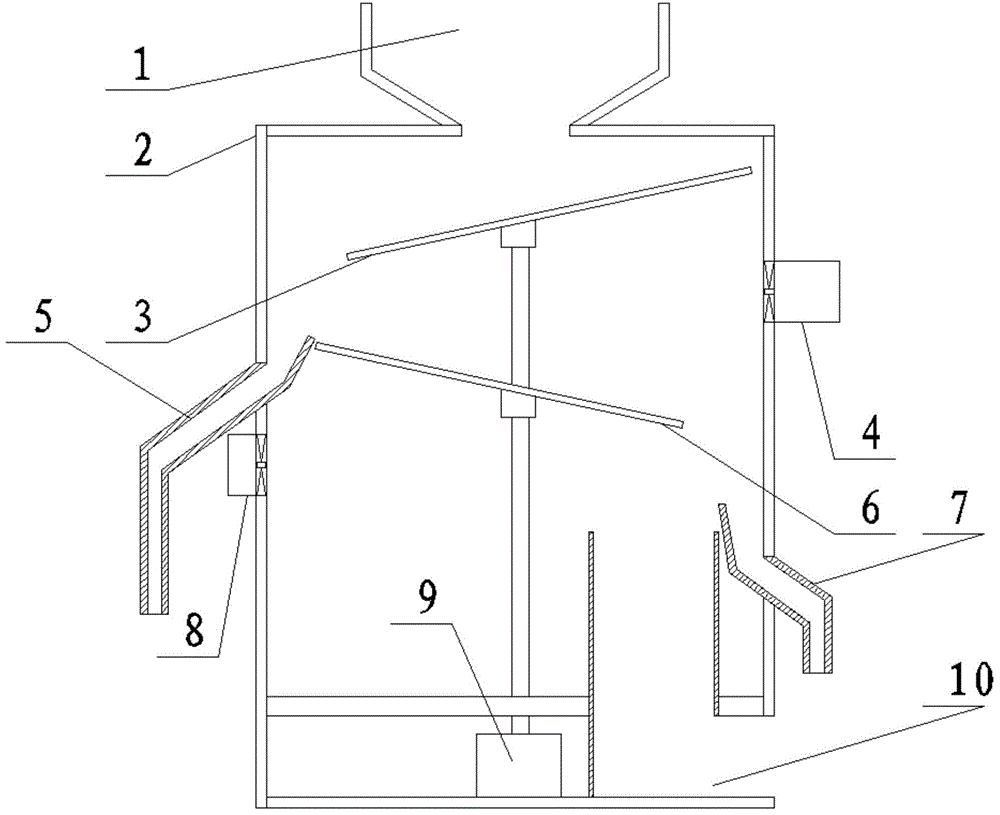

[0014] figure 1 Shows the specific implementation of the present invention, the present invention is a new type of garbage sorting machine, including a hollow shell 2, the top center of the shell 2 is provided with a garbage inlet 1, and the bottom of the garbage inlet 1 inside the shell 2 is set to tilt to the left The first distribution plate 3 of the housing 2 is equipped with a first outlet 5 on the side wall near the left end of the first distribution plate, and the side wall at the other end of the housing 2 is located at the right end of the first distribution plate and the first The first distribution fan 4 is installed at the position between the upper edges of the outlet 5, and the air outlet of the first distribution fan 4 faces the inside of the housing 2;

[0015] Inside the above-mentioned housing 2, a second distribution plate 6 is arranged obliquely to the right below the first outlet 5, and a second outlet 7 is installed on the side wall of the housing 2 near ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com